Water Supply Pipeline Safety revolutionized with Environmentally-Friendly Sensors

The Intelligent Wave Engineering Team of the Korea Research Institute of Standards and Science (KRISS) and the Electro Ceramics Laboratory of the Department of Materials Science and Engineering at Korea University (KU, Principal Dong-won Kim) have collaborated to develop a cutting-edge ultrasound sensor that ensures the safety of large structures, especially water supply pipelines.

The inspection of water supply pipelines using guided waves is a non-destructive testing method used to detect damage such as corrosion within the pipes. The key advantage of this method lies in its capacity to cover a wide range with minimal sensor deployment.

The problem, however, is that most of the guided wave sensors are made from piezoelectric materials which contain lead, a well-known hazardous metal. The RoHS, an eco-friendly certification system in Europe, strictly restricts the use of lead in electronic products and other applications because of its dangerousness.

The KRISS-KU joint research team finally developed the guided wave sensors using lead-free piezoelectric materials. They address the concerns related to health and environmental hazards as well as show superior performance compared to existing lead-based sensors.

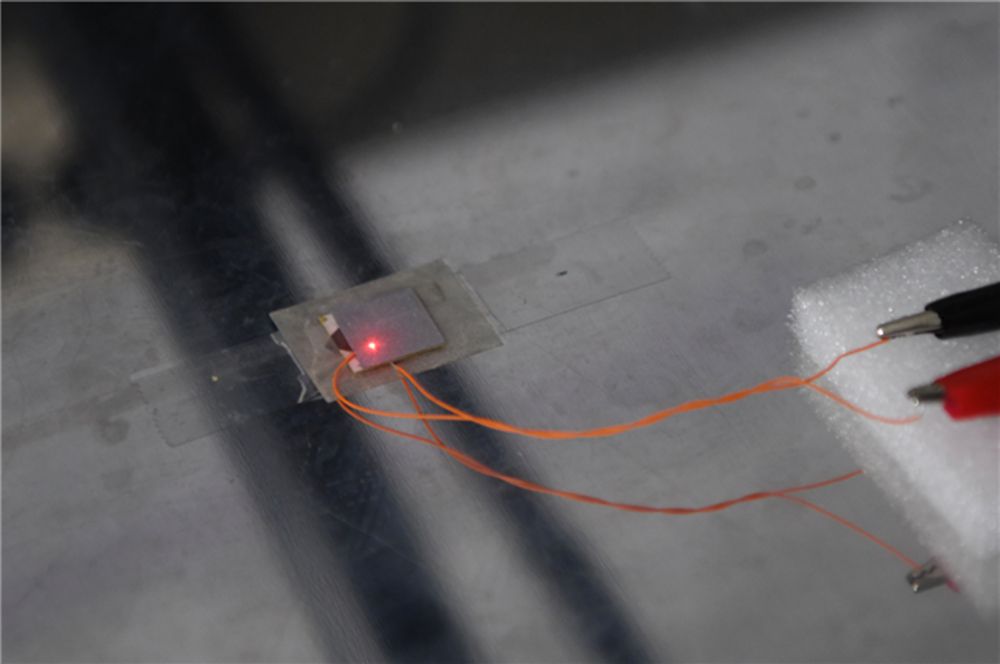

The newly developed sensor is a 360-degree omnidirectional sensor that emits signals evenly in all directions. Operating in the shear wave mode of ultrasound, it is highly effective for inspecting pipelines even when the water is flowing inside the pipes without the loss of energy.

To maximize the output efficiency in the shear wave mode, the research team creatively redesigned the sensor component using a unique trapezoidal shape. This, combined with the lead-free materials, resulted in a remarkable increase in output intensity of the shear wave mode, surpassing that of traditional lead-based sensors by more than 15 %.

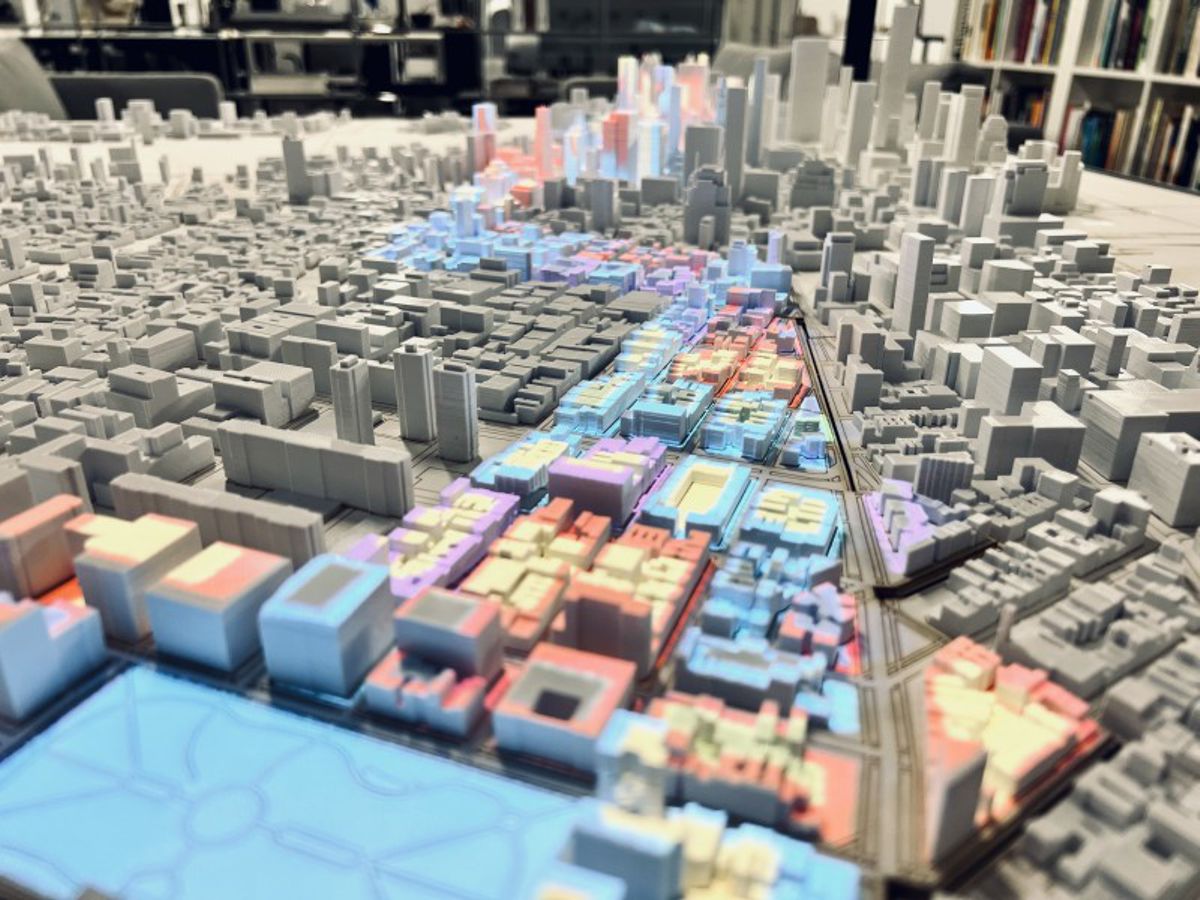

This achievement is expected to transform the method of inspection of pipelines. The conventional spot inspection was carried out by the visit of inspectors at regular intervals, but unmanned continuous monitoring which covers a broad area can be feasible. Unmanned monitoring of pipelines using guided wave non-destructive testing is already being introduced in English-speaking and European countries.

Dr. Hong Min Seung, a senior researcher from the Intelligent Wave Engineering Team of KRISS, said, “The newly developed lead-free sensor is made from environmentally-friendly materials, ensuring its safe use even when installed in pipelines for a long time because it does not affect surrounding environment or water quality.

Additionally, this technology will contribute to strengthening the competitive edge of domestic companies in the global non-destructive testing market, spanning industries such as manufacturing, construction, and more.