Cutting-Edge Technologies: CNC Laser versus Waterjet

In the dynamic world of modern manufacturing, two cutting technologies stand out: CNC Laser and CNC Waterjet cutting. These advanced methods have revolutionized material processing, offering precision, versatility, and efficiency.

This comprehensive guide delves deep into each technology, comparing their capabilities, applications, and suitability for various industrial needs.

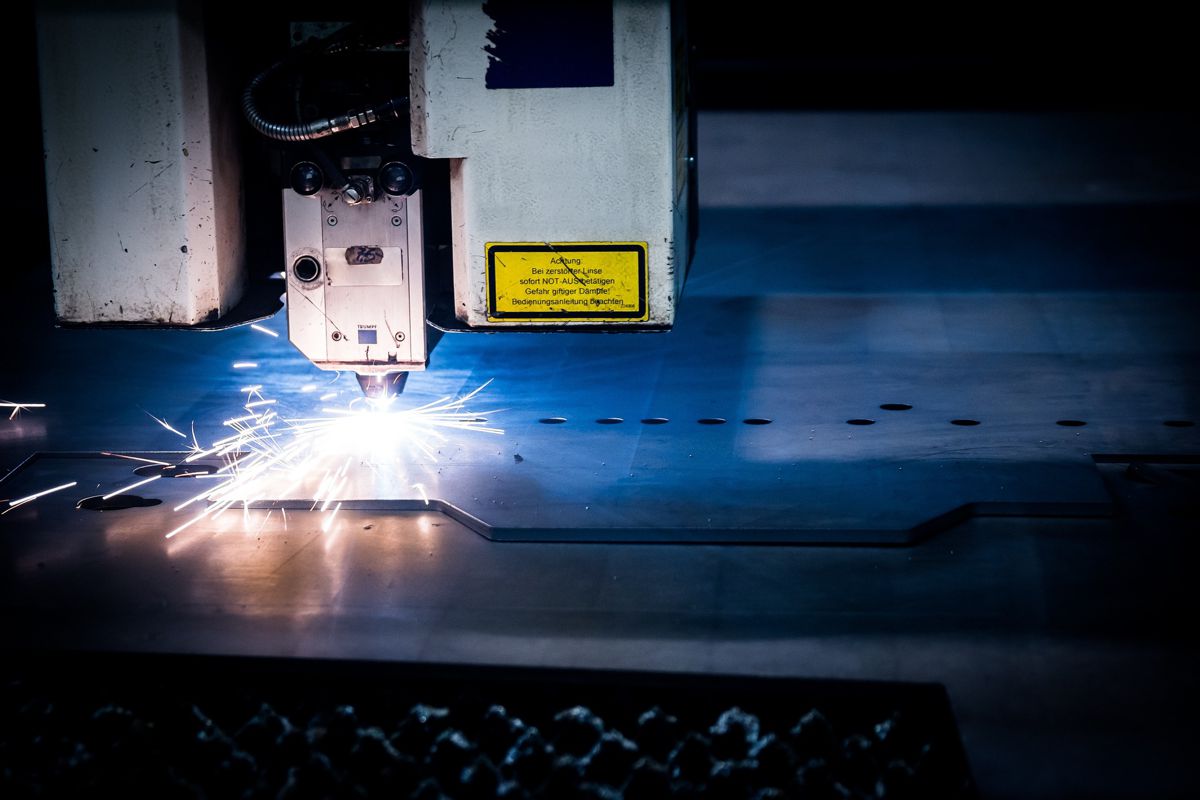

CNC Laser Cutting: A Detailed Insight

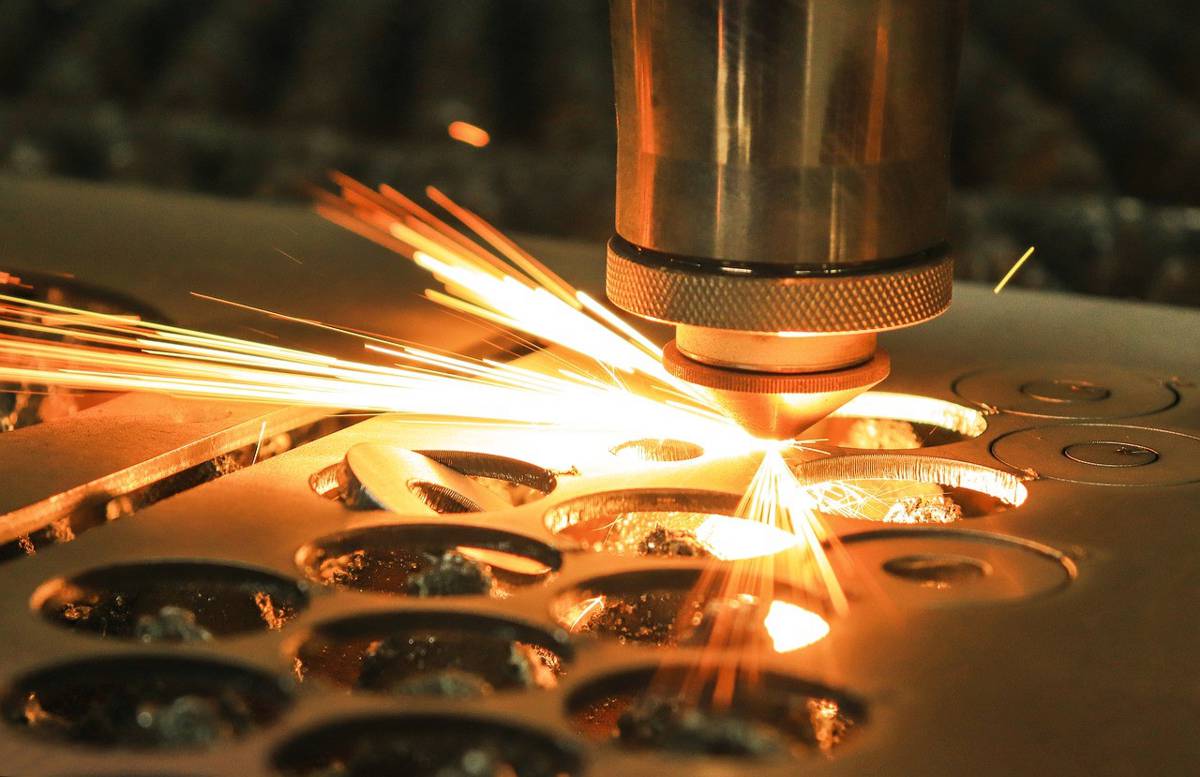

How Does CNC Laser Cutting Work?

Understanding the process of CNC laser cutting is crucial in appreciating its technological prowess. The procedure involves:

- Generating the laser beam

- Directing the beam onto the material

- Precisely melting or vaporizing the material

- Removing the excess material to create a clean cut

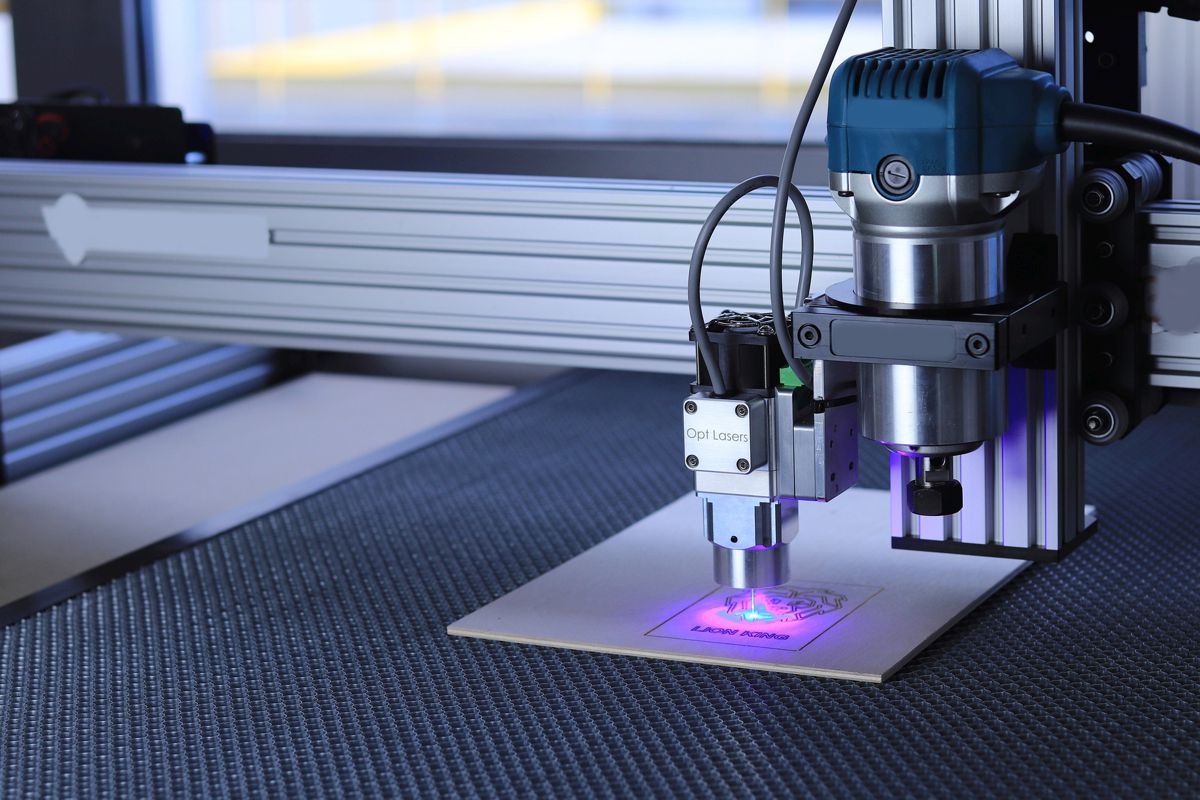

Types of CNC Laser Cutters

The world of CNC laser cutters is diverse, each type offering unique advantages and challenges.

- Fiber Laser Cutters: ACCURL CNC fiber laser cutter machines are known for their energy efficiency and cutting speed, especially for thinner materials. However, they can struggle with thicker material cuts.

- CO2 Laser Cutters: CO2 laser cutters excel in cutting thicker materials and offer versatility across various materials. Their downside lies in higher operational costs and maintenance.

- Nd:YAG Laser Cutters: These cutters are perfect for applications requiring high energy but are less efficient in terms of electricity consumption and require more maintenance.

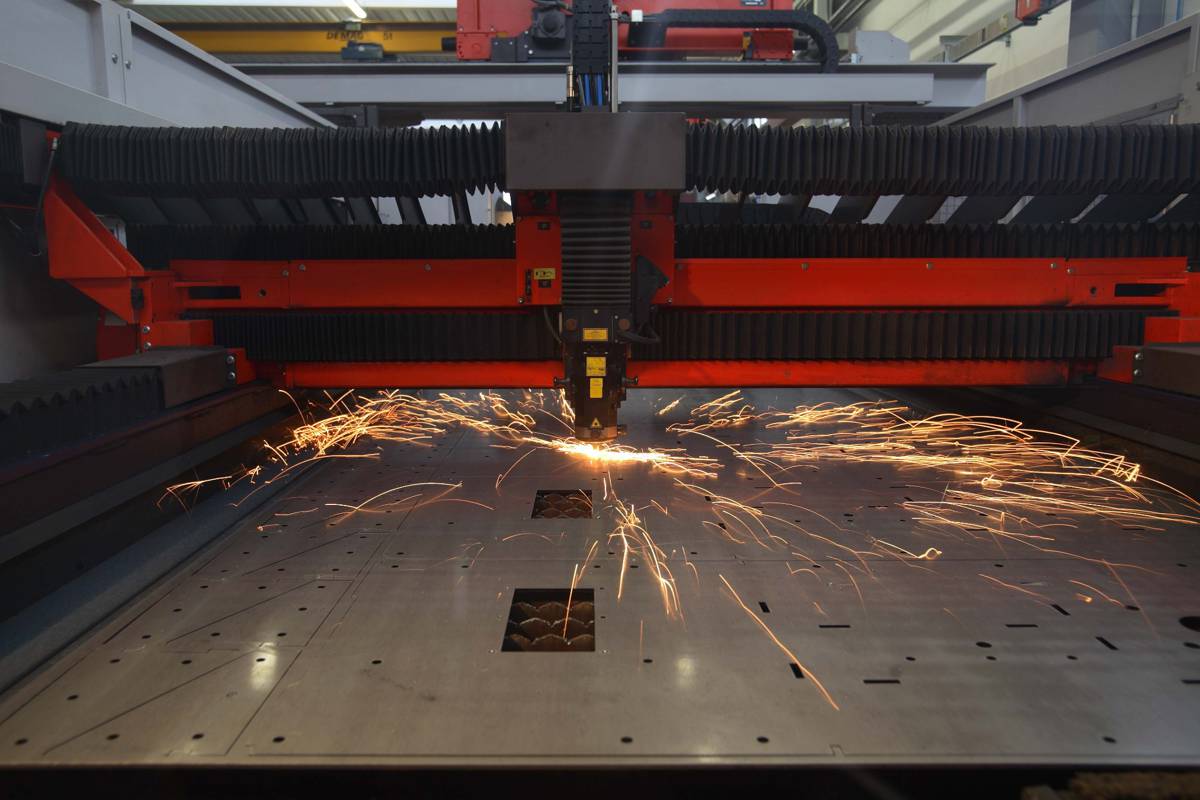

Key Components of a CNC Laser Cutter

Key components include:

- Laser source

- Cutting head

- Control system

- Gas supply system

Parameters of CNC Laser Cutting

Important parameters in CNC laser cutting include:

- Laser power

- Focal length of the lens

- Cutting speed

- Assist gas pressure

Cutting Tolerances for Different Materials

The tolerance levels can vary significantly depending on the type of material being cut.

Maximum Cutting Thickness

This parameter varies with laser power and material type, usually ranging from a few millimeters to several inches.

Laser Power and Speed Settings

Power and speed settings are adjustable and need to be optimized for each material and thickness.

Exploring CNC Waterjet Cutting

How Does CNC Waterjet Cutting Work?

CNC waterjet cutting involves:

- Generating high-pressure water

- Focusing the water stream on the material

- Eroding the material through the waterjet

- Creating a precise cut without heat

Types of CNC Waterjet Cutters

The variety in waterjet cutters offers different benefits and drawbacks.

Key Components of a CNC Waterjet Cutter

Essential parts include:

- High-pressure pump

- Cutting table

- Control system

- Abrasive feed system

Parameters of CNC Waterjet Cutting

Important parameters to consider:

- Water pressure

- Abrasive type and feed rate

- Cutting speed

- Nozzle size

Cutting Tolerances and Quality

Tolerances in waterjet cutting are generally higher, especially for thicker materials.

Maximum Cutting Thickness

Waterjets can handle very thick materials, often more than what laser can manage.

Water Pressure and Abrasive Types

Adjusting these parameters is key for optimal cutting performance.

Comparing CNC Laser and Waterjet Cutting

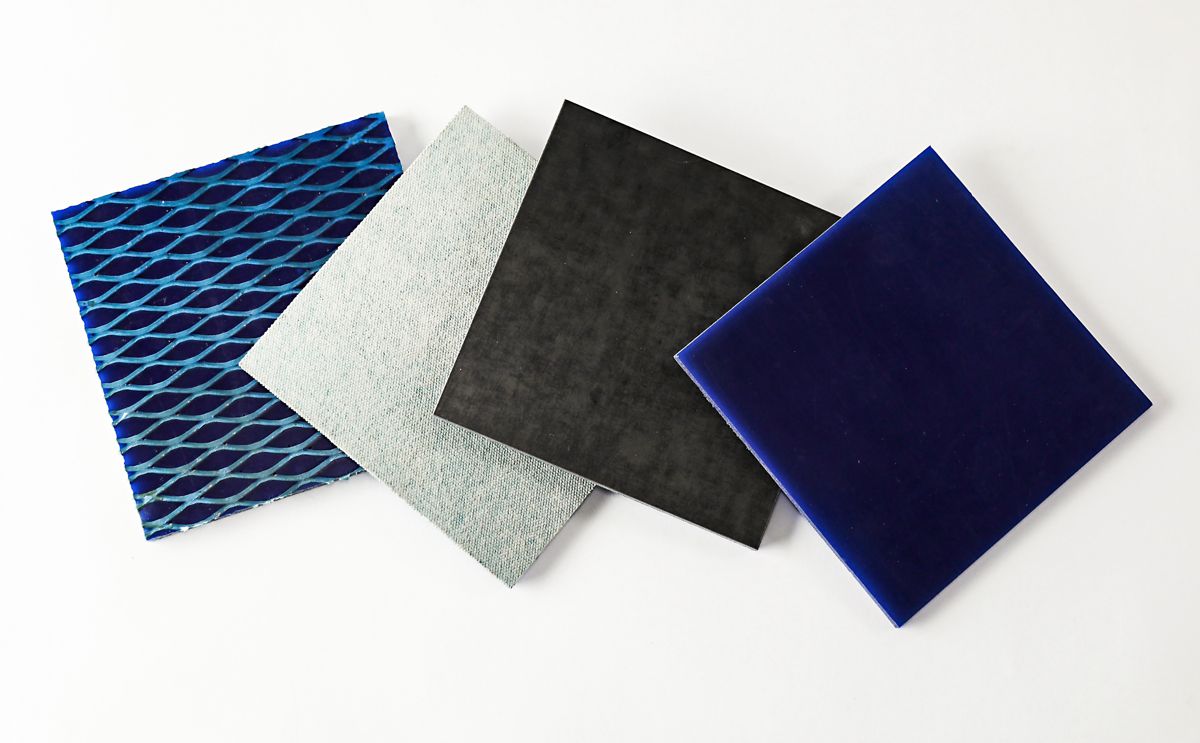

Material Compatibility and Limitations

Materials best suited for each method include:

- Laser: Metals, plastics, and organics

- Waterjet: Virtually any material

Precision and Quality of Cut

While both offer high precision, laser cutting edges are generally smoother, whereas waterjet leaves a slightly rougher finish.

Speed and Efficiency

Laser cutting is typically faster for thinner materials, while waterjet excels with thicker and harder materials.

Operating Costs and Maintenance

Laser cutting has higher energy costs and maintenance, while waterjet involves higher costs for abrasives and pump maintenance.

Safety Considerations

Safety protocols differ, with laser requiring protection against laser light and waterjet needing safety measures for high-pressure operation.

Advantages and Disadvantages

Advantages of CNC Laser Cutting

Advantages include:

- Accuracy and precision

- Faster speeds for thin materials

- Flexibility in cutting various materials

Disadvantages of CNC Laser Cutting

Drawbacks involve:

- Limited thickness

- Higher operational costs

Advantages of CNC Waterjet Cutting

Benefits feature:

- Versatility in cutting thick and diverse materials

- No heat-affected zone

Disadvantages of CNC Waterjet Cutting

Challenges include:

- Slower speeds for certain materials

- Higher abrasive costs

Applications in Industry

Industries and applications vary widely, from aerospace (precision parts) to art and design (intricate patterns).

Choosing the Right Cutting Technology

Key factors include:

- Material type and thickness

- Required precision and edge quality

- Production speed

Guidelines for Specific Applications

Recommendations vary based on material and application, with laser often preferred for metals and thin materials, and waterjet for thicker, harder materials.

Future Trends and Innovations

The future holds promising advancements in both technologies, with a focus on increasing efficiency, precision, and material versatility.

Selecting between CNC laser and waterjet cutting depends on specific project requirements. Each technology offers unique advantages and limitations, and the choice should align with the material, desired precision, and cost considerations.

As the industry evolves, these technologies continue to offer increasingly sophisticated solutions for diverse cutting needs.