Sydney Metro proves to be Doka’s largest tunnelling civil works project

The new Sydney Metro standalone railway will deliver 31 metro stations and more than 66 kilometres of new metro rail, revolutionising the way Australia’s biggest city travels.

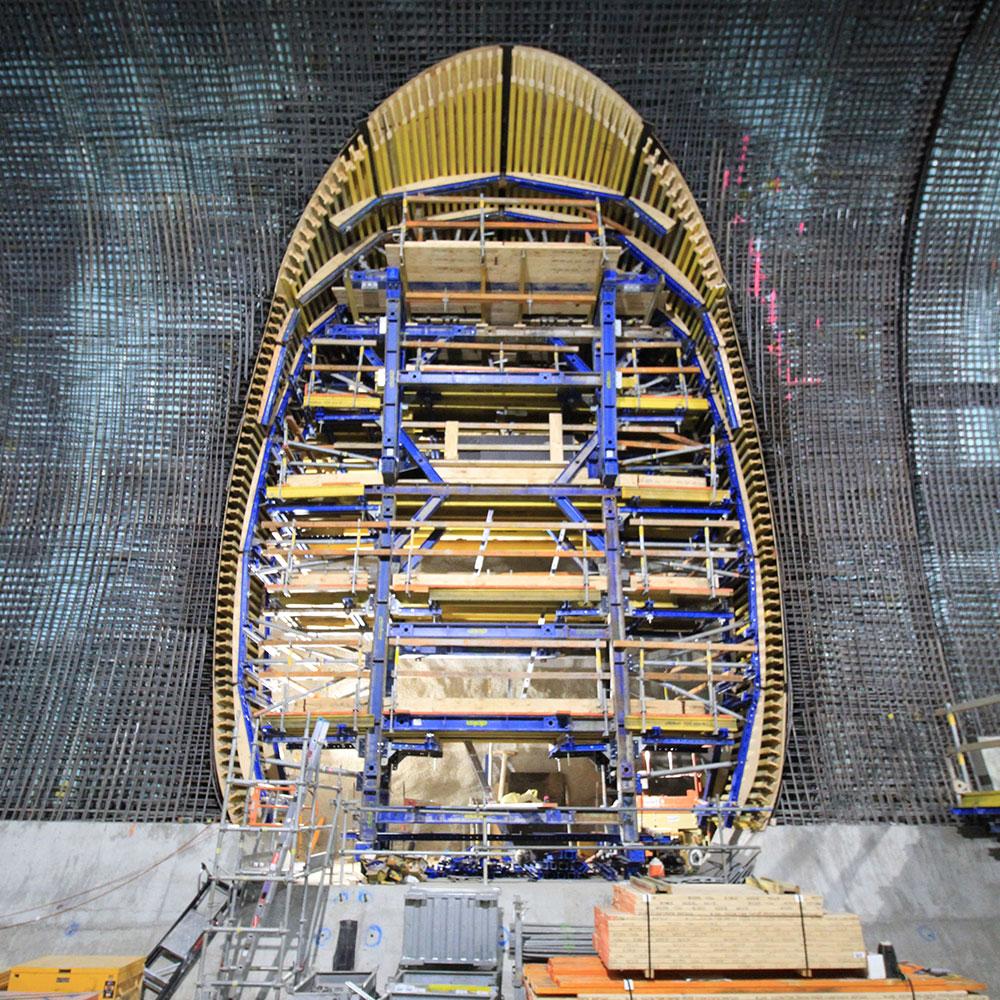

Doka supplies formwork engineering services, material and equipment supply for the mined tunnel concrete lining construction at Martin Place, Pitt Street and Victoria Cross Station sites.

When Sydney Metro is extended into the central business district (CBD) and beyond in 2024, metro rail will run from Sydney’s booming North West region under Sydney Harbour, through new underground stations in the CBD and beyond to the south west. Sydney’s new metro railway will have a target capacity of about 40,000 customers per hour, similar to other metro systems worldwide.

Sydney’s current suburban system can reliably carry 24,000 people an hour per line. Sydney Metro, together with signaling and infrastructure upgrades across the existing Sydney rail network, will increase the capacity of train services entering the Sydney CBD – from about 120 an hour today to up to 200 services beyond 2024. That’s an increase of up to 60 per cent capacity across the network to meet demand.

The project has become a showcase for Doka’s heavy-duty supporting system SL-1; a modular system, which provides complete formwork solutions for widely differing tunnel cross-sections, regardless of shape and load. As the company’s largest involvement to date in major tunneling civil works, Sydney Metro has drawn on other Doka strengths.

Doka Global Expertise Centre (GEC) for tunnel infrastructure, based at the headquarters in Austria, has been heavily involved in the project. It will account for more than 20,000 engineering hours to design formwork sub-structures for the concrete, which will line and support the massive underground station caverns and tunnel intersections. Doka’s ability to turn around engineering solutions quickly, by drawing on its own design expertise in another hemisphere where time zones allow such collaboration, has been a success.

Unique formwork solutions for tunnel intersections

Standard but specialised Doka SL-1 components and modules have been employed for most requirements, but Doka Australia has also drawn on its parent company’s expertise to design and manufacture custom accessories. Doka worked intensively to produce unique formwork designs for all mined tunnel intersections, pedestrian and service adits at Martin Place, Pitt Street & Victoria Cross Station sites.

Each individual mined tunnel profile and intersection requires unique designs for off-site pre-assembly and on site installation for the in-situ concrete pour.

Doka’s team is in constant communication, meetings and workshops with the JHCPBG site engineering teams and subcontractors. This approach ensures all parameters and requirements are considered in finding the best solution to increase the efficiency and safety of the work.

“Doka has demonstrated a willingness to tackle the complex and unique challenges of our project, which has resulted in a high level of collaboration between the construction teams and Doka’s local and international branches”, emphasized Benjamin Russo, Planning & Engineering Manager, Mined Tunnels.

The deliveries started in early 2019 and Doka materials will be used through to late 2020 when construction of concrete lining finishes. The Doka heavy-duty supporting system SL-1 is extremely adaptable. SL-1 beams, walings and struts can be arranged in variable configurations, enabling optimum use to be made of each item of equipment, with short set-up times and Heavy-duty supporting-unit components. Built-in safety systems ensure high workplace safety including integrated work platforms and ladderways.