VINCI Energies looks at 5 ways smart industry will boost manufacturing

Contrary to perception, the UK manufacturing sector is already on the rise thanks to increased investments in skills and technology. By taking a lead in automation and networking, the UK could accelerate this growth further still.

Politicians and press often lament the state of the UK manufacturing industry but the situation is actually nowhere near as dire as the picture they paint. While we are not quite at 1970s levels, when manufacturing contributed 25% of UK GDP, the sector is steadily increasing and we are still among the top 10 manufacturing economies in the world.

Reasons behind this growth include a shift in production from low to high-value goods, a more skilled workforce and, crucially, investment in automation and technology. Further investments in the next generation of ‘smart factories’ – where machines communicate with each other to carry out each stage of the manufacturing process with degrees of speed, flexibility and efficiency never seen before – will only accelerate this positive trend.

Here we investigate five ways smart industry makes an attractive proposition for both businesses and consumers.

1. Increased productivity

Automation brings a step change in the productivity and efficiency of factory operations but workflows still have to be programmed and scheduled for each batch.

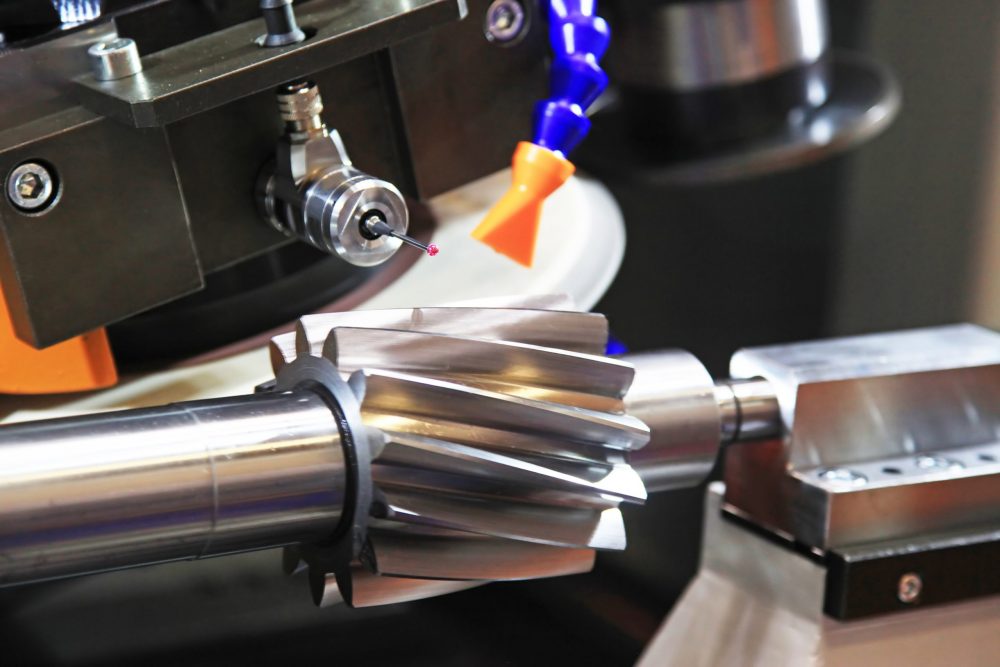

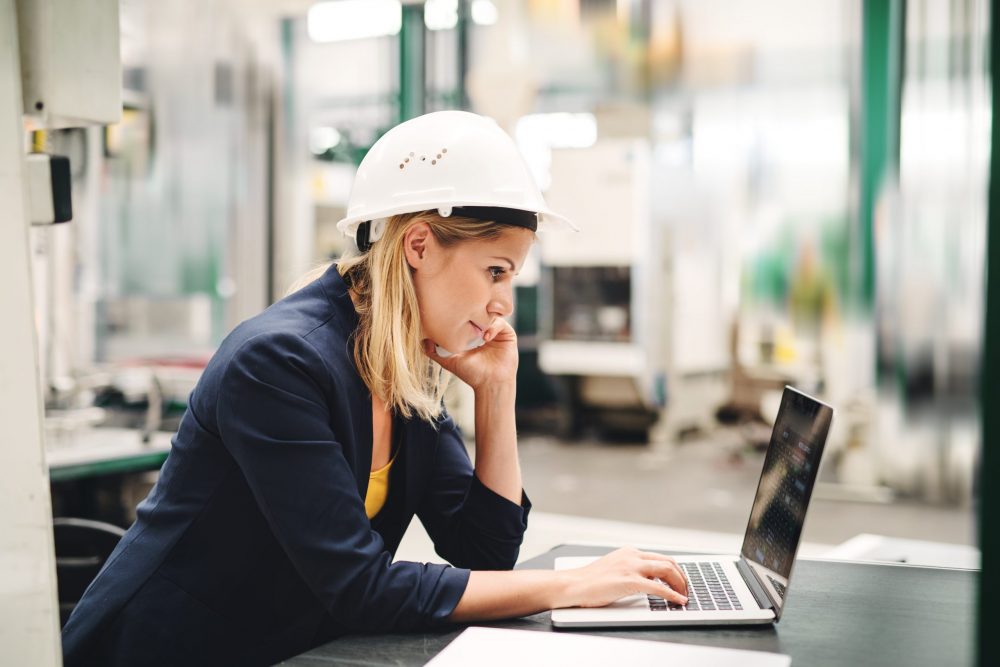

In a smart factory, however, automated machines are enhanced with additional electronics, software and sensors that enable them to talk to each other via a network and coordinate their own work to meet constantly changing demands with minimal human involvement.

The factory can almost run itself, taking smart decisions and adapting in real-time to maximise output and – by extension – profitability.

2. Consistent quality and traceability

Automated machines, by their very nature, improve the uniformity of goods produced. Smart machines take this consistency to the next level by performing quality checks throughout the manufacturing process and making adjustments where necessary.

Should an inferior quality product somehow make it all the way through the production line, data stored in the machines allow supervisors to discover exactly what went wrong and at what stage for rapid and precisely-targeted recalls.

In this way, UK manufacturing could guarantee the high quality that it has long been known for.

3. Short and reliable delivery times

In today’s fast-paced world, we expect to receive our orders quickly but a container of goods from China can take over a month to arrive by boat and pass through customs.

By making UK manufacturing more cost-effective, smart industry enables goods to be produced closer to the customer where they can be delivered quicker. Meanwhile, the ability of a smart factory to balance scheduling and workflows and perform quality checks throughout increases the speed of manufacturing, while reducing the potential for hold-ups. And because the status of goods is also tracked throughout, manufacturers can provide accurate and reliable lead times to their customers.

4. Easy customisation

Along with fast delivery, personalisation has also become an important expectation in our society.

We all want something unique that perfectly suits our needs. In a traditional factory varying the characteristics of each individual item produced is time and labour-intensive, driving up costs.

However, this is not the case in a smart factory where intelligent machines can quickly recalibrate themselves on the fly to vary parameters – size, colour packaging etc., while maintaining speed and efficiency.

5. Strong ethics

Finally, customers today care more and more about the provenance of goods and how they are made. We don’t wish to support any supplier that exploits people or causes unnecessary harm to the environment.

Smart industry in the UK can earn a reputation for ethics on the global stage as employees are treated well – staff are kept out of harm’s way and assigned to skilled tasks that add value – and energy consumption is significantly lower.

By cleverly coordinating their work and shutting down when idle, smart machines reduce energy consumption. An intelligent connection to the grid and renewable energy sources can also ensure that green energy is used whenever possible.

As we have seen, smart industry can boost the competitiveness of UK manufacturing from more than just a cost perspective – also promoting reliably high quality, short lead times, personalisation and strong ethics. But there aren’t currently many companies in the UK equipped to supply all the complex interrelating aspects of upgrading a facility into a smart factory.

With expertise in factory efficiency, ICT and energy infrastructure all under one roof, VINCI Energies UK & RoI is ready to help bring about a new age of manufacturing in the UK.