Construction of Vaccine Manufacturing and Innovation Centre fast tracked in Oxford

Construction of the UK’s New Vaccines Centre by Glencar Construction Starts Well Ahead of Schedule as Timelines are Fast Tracked Due to Covid-19

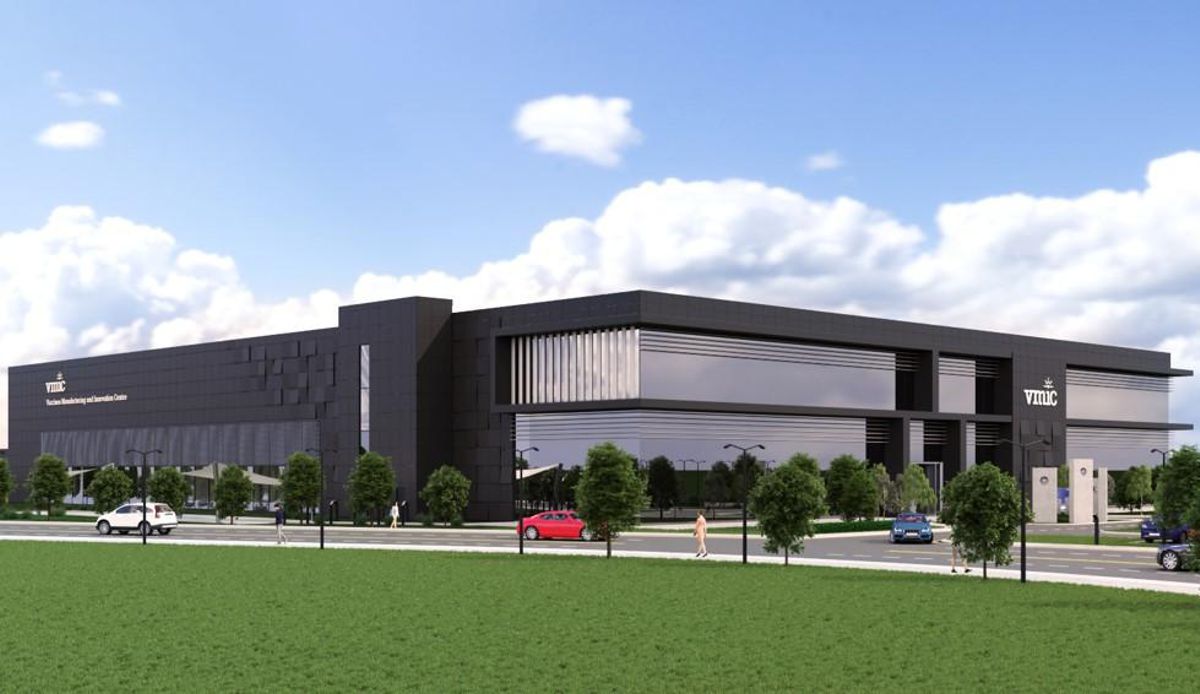

Construction work has begun ahead of schedule to build the highly specialist facility that will house the Vaccines Manufacturing and Innovation Centre (VMIC). VMIC, a not for profit organisation, will provide the country’s first bespoke strategic vaccine development and manufacturing capability.

A rapidly accelerated programme will aim to see the 7,000 m2 (75,000 sq ft – footprint) state-of-the-art facility opening its doors in 2021, ahead of the original scheduled date in 2022. An unprecedented collaborative effort between The Vaccines Manufacturing and Innovation Centre, Harwell Campus, Vale of the White Horse District Council, UK Research and Innovation, and Glencar Construction, the main contractor, has accelerated the construction of this complex build in order to bring the facility online early so that it can provide an emergency response capability for the UK.

Ground works began on the site at Harwell Campus in early April and have focused on site clearance, preparing the site for construction and the early order of the steelwork. Glencar expect to see the base build ready for early access for fit-out, in late July/early August. Design and fit out are underway and led by WHP Engineering.

Dr Matthew Duchars, Chief Executive of the Vaccines Manufacturing and Innovation Centre said: “Whilst no-one could have predicted the Covid-19 outbreak we are doing all we can to fast track the build so VMIC is set-up to offer long-term support to the UK’s future vaccines needs whilst simultaneously contributing right now to the vital work that will help us emerge from this pandemic.

“As well as working with the Harwell team and contractors to deliver the build rapidly ahead of schedule, VMIC scientists and engineers are working round the clock as part of the BIA CoViD19 Taskforce, and alongside Oxford University advising on manufacturing options of the vaccine candidate ChAdOx1 nCoV-19, which has recently opened for trial.”

Cliff Dare, Chief Operating Officer of Harwell Campus Management team and Development Manager for the VMIC build said: “This is an unprecedented time and one that calls for collaboration across many fields and sectors. We are working closely with Matthew and his team, national and local government, and Glencar the main contractor involved on this complex development. It is essential that we continue to fast track this project of national importance, bringing the facility into operation as quickly as possible.

“This is not a straightforward build and fit out; it is a complex advanced centre of technology and that throws up its own particular challenges. One way we are addressing this is by looking at novel strategies for developing fit out / technologies, including off-site manufacture that will sit within the building to be developed alongside groundworks.”

Eddie McGillycuddy, Managing Director of Glencar Construction said: “Glencar is pleased to collaborate with VMIC, Harwell, The Vale of White Horse Council and other stakeholders to deliver this critical project. We have made an accelerated start and reduced our construction programme with the support of our partners, making this project an excellent example of all that is good about our industry.”

Chris Lucas, Chief Operating officer, VMIC: “The programme acceleration to allow VMIC to open its doors in 2021, a year ahead of schedule, with the concurrent increase in capability to cater for pandemic response has only been possible by an extraordinary level of cooperation by all concerned.

“Working hand in hand with the VMIC organisation in an integrated team, the entire project organisation; from the design and construction contractors, the landlord, specialist consultants and together with support from local and national government; has geared up to the challenge of meeting the revised requirements, focussed on collaboration to deliver this critical resource both in the battle against pandemic viruses and the rejuvenation of the vaccines industry in the UK.”

VMIC will occupy a prominent location on the 700-acre Harwell Campus home to 6,000 people across ~225 organisations [with 30 universities represented onsite]. As a pillar organisation with the Harwell HealthTec Cluster (58 organisations, collectively employing 1,250 people), VMIC will be co-located with the UK’s open access National Laboratories, including the Diamond Light Source and The Rosalind Franklin Institute as well as innovative start-ups/ SMEs through to multinationals working in the global and UK Life Sciences sector.

Research and commercial work on the multi-disciplinary Campus spans everything from drug discovery, including fragment screening, AI-enhanced drug design, vaccines, vectors and advanced medicines, through to environmental impacts on human health, biomaterials and ageing. This work is underpinned by globally unique multi-modal imaging expertise and capabilities in structural biology, genomics, big data analytics, super-computing, and satellite enabled digital connectivity. Collaboration between researchers, industry, academics, and government teams working across this broad spectrum of activity is at the heart of the Campus. During the last few months, many organisations at Harwell have been pivotal players alongside VMIC in the Covid-19 battle, including: Diamond Light Source, Oxford Nanopore, Public Health England, University of Oxford, RAL Space and ResMed.

VMIC was established by University of Oxford, Imperial College and London School of Hygiene and Tropical Medicine with support from industrial partners, Merck Sharp and Dohme, Johnson and Johnson, and GE Healthcare. The Centre’s main funding comes through a £65 million grant from UK Research and Innovation, as part of the UK Government’s Industrial Strategy Challenge Fund.