Bosch shows coronavirus commitment with technological innovations

After shutting down production at nearly 100 Bosch locations worldwide this month, the company is systematically preparing for a gradual ramp-up of manufacturing.

“We want to ensure reliable supplies to meet our customers’ demand as it gradually returns, with a view to helping the world economy recover as quickly as possible,” said Dr. Volkmar Denner, chairman of the board of management of Robert Bosch GmbH, at the company’s annual press conference.

“Our goal is to synchronize the ramp-up of production and secure supply chains, especially in automotive production. We have already achieved this in China, where our 40 or so local plants are producing again and the supply chains are stable. We are working hard to do the same in our other regions.” To make a success of ramping up production, Denner said that the company is putting numerous measures in place to ensure that associates are adequately protected against coronavirus infection. Bosch is also committed to taking a coordinated, joint approach with customers, suppliers, authorities, and employee representatives.

Helping contain the coronavirus pandemic

“Wherever possible, we want to contribute our expertise to efforts to contain the pandemic, for instance through our newly developed rapid Covid-19 test and our Vivalytic analysis device,” Bosch CEO Denner said. “Demand is huge. We’re doing everything we can to significantly increase production, and will increase capacity five-fold over our original plans by the end of the year,” he continued.

Bosch intends to produce more than a million rapid tests in 2020, and to increase this to three million next year.In addition to existing laboratory tests, the Vivalytic analysis device is to be used initially in hospitals and doctors’ offices, where it will be used primarily to protect medical staff, for whom the rapid availability of test results in less than two-and-a-half hours is crucial. The rapid test is already being delivered to European customers with a “research use only” label, and can be used following validation. Bosch expects to have a CE mark for the product by the end of May. An even faster test, which can reliably detect Covid-19 cases in less than 45 minutes, is in the final stages of development. “All our work in this field is guided by our ‘Invented for life’ ethos,” Denner said.

Bosch has already started production of face masks. Even now, thirteen Bosch plants in nine countries – from Bari in Italy, to Bursa in Turkey, to Anderson in the United States – have taken the initiative and are making such masks for local requirements. In addition, the company is currently setting up two fully automatic production lines at its Stuttgart-Feuerbach location with further lines to follow at its German Erbach location as well as in India and Mexico.

“It took our special-purpose machinery unit just a few weeks to design the necessary machinery,” Denner said. Bosch has also made the designs available to other companies free of charge. This means the company will be able to manufacture more than 500,000 masks per day. The masks are intended to protect Bosch associates at plants worldwide. Furthermore, the aim is to make them available to third parties as well. This will depend on gaining the appropriate country-specific approvals. In addition, Bosch is producing 5,000 liters of disinfectant each week in Germany and the U.S. for its associates in American and European plants. “Our people are doing great work here,” Denner said.

Global economic development in 2020: recession negatively affecting outlook

In view of the coronavirus pandemic, Bosch anticipates considerable challenges for the global economy in the current business year: “We are bracing ourselves for a global recession that will also have a considerable impact on our own performance in 2020,” said Prof. Stefan Asenkerschbaumer, CFO and deputy chairman of the Bosch board of management. Based on the effects known to date, Bosch currently expects automotive production to fall by at least 20 percent in 2020.

In the first quarter of this year, Bosch Group sales fell by 7.3 percent, meaning they are already considerably lower year on year. Sales dropped by 17 percent in March 2020 alone. Given the many imponderables, the company felt unable to make a forecast for the year as a whole. “A supreme effort must be made to achieve at least a balanced result,” the CFO said. “In this severe crisis, it is again an advantage for us that we are so diversified, with different business sectors.”

Currently, the focus is on extensive measures to reduce costs and secure liquidity. This includes reductions in working hours and cutbacks in production already in place at many locations worldwide, salary reductions for specialists and managers including executive management, and extended time frames for investments. In addition, Bosch had already launched a comprehensive program to improve its competitiveness at the beginning of 2020.

“In the medium term, our objective is to return to a roughly 7 percent margin from operations, but without neglecting the essential tasks to secure our future,” Asenkerschbaumer said. “We are devoting all our energy to this and to overcoming the coronavirus pandemic. In this way, we will create the financial foundations we need to seize the huge opportunities that lie ahead for the Bosch Group.”

Climate action: Bosch is systematically pursuing ambitious goals

Despite the challenges of the current situation, Bosch is maintaining its long-term strategic course: the supplier of technology and services is continuing with its systematic pursuit of ambitious climate goals and is developing the activities required to support an expansion of sustainable mobility. “Although other issues are currently in the spotlight, we must not lose sight of the future of our planet,” Denner said.

About a year ago, Bosch announced that it would be the first globally operating industrial enterprise to become climate neutral by the end of 2020, and this at all its 400 locations worldwide. “We will achieve this goal,” Denner said. “At the end of 2019, we achieved carbon neutrality for all our locations in Germany; as of today, we are 70 percent of the way to achieving this worldwide.” To make carbon neutrality a reality, Bosch is investing in energy efficiency, increasing the proportion of renewables in its energy supply, buying in more green power, and offsetting unavoidable carbon emissions. “The share of carbon offsets will be significantly lower than planned in 2020, at just 25 percent instead of nearly 50 percent. In other words, we are making faster progress than we expected in improving the quality of the measures we take,” Denner said.

Carbon-neutral economy: new advisory company established

When it comes to climate action, Bosch is taking two new approaches to ensure its own efforts have a multiplier effect in the economy. One goal is to make upstream and downstream activities along the value chain as climate neutral as possible, from “purchased goods” to “use of products sold.”

By 2030, the associated emissions (Scope 3) are expected to fall by 15 percent, or more than 50 million metric tons per year. To this end, Bosch has agreed on a target with the Science-Based Targets initiative, making Bosch the first automotive supplier to commit to a measurable target. Moreover, the company plans to pool the knowledge of nearly 1,000 Bosch experts worldwide and experience from more than 1,000 energy-efficiency projects of its own in a new advisory company, called Bosch Climate Solutions. Explaining this step, Denner said: “We want to make our experience available to other companies, to help them progress to carbon neutrality,”

Growth market for Europe: venturing into the hydrogen economy

“Climate action remains crucial for humanity’s survival. It costs money, but doing nothing will cost even more,” Denner said. “Politics must not stand in the way of companies expanding their ingenuity and using technology to benefit the environment – without harming prosperity.” According to Denner, what is important is a broad technology offensive that not only sets out a battery-electric path to sustainable mobility, but also takes into consideration efficient combustion engines and especially renewable synthetic fuels and fuel cells.

The Bosch CEO called for a bold move into the hydrogen economy and the production of renewable synthetic fuels once the coronavirus crisis has passed. In his view, this is the only way Europe can become climate-neutral by 2050. “Today’s hydrogen applications need to make it out of field testing and into the real economy,” Denner said. He appealed to policymakers to support the necessary technologies: “This will enable us to achieve even ambitious climate targets.”

Ready for hydrogen: mobile and stationary fuel cells

Climate action is accelerating structural change in many sectors. “Hydrogen is becoming increasingly important, both in the automotive industry and in building technology. Bosch is very well prepared for this,” Denner said. Bosch and its partner Powercell are already working to commercialize mobile fuel-cell stacks for use in vehicles. Their market launch is planned for 2022. This is how Bosch intends to position itself successfully in another growth market: As early as 2030, one in eight newly registered heavy trucks could be powered by a fuel cell. Bosch is working with its partner Ceres Power on stationary fuel cells. These can supply buildings such as computing centers with electricity. Bosch anticipates that the market for fuel-cell power stations will be worth more than 20 billion euros by 2030.

Powertrain and heating technology: electrification of the product portfolio

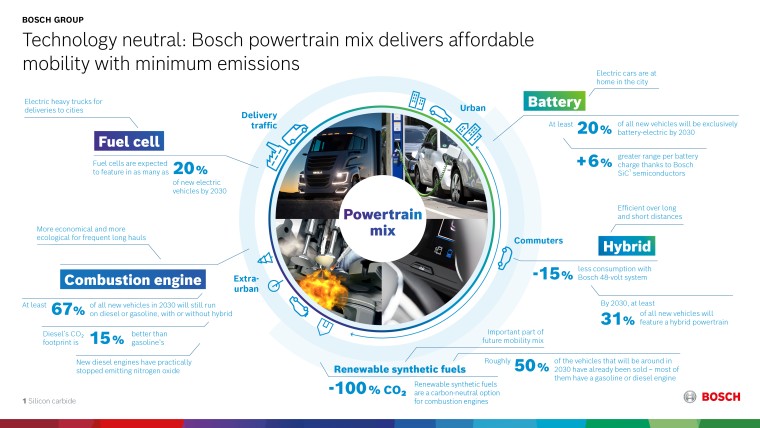

“As climate action is stepped up, electrical solutions will be limited in the near term to complementing the combustion solutions that have dominated up to now,” Denner said. That is why Bosch is pursuing technology-neutral powertrain development. According to Bosch market research, two out of every three newly registered vehicles in 2030 will still run on diesel or gasoline, with or without a hybrid option. That is why the company is also continuing to invest in highly efficient combustion engines.

Thanks to Bosch’s new exhaust technology, diesel engines’ NOx emissions have been almost completely eliminated, as independent tests have already shown. Bosch is also systematically refining the gasoline engine: modifications to engines and efficient exhaust-gas treatment can now bring particulate emissions down to a level roughly 70 percent lower than the Euro 6d temp standard. In addition, Bosch is committed to renewable fuels, since legacy vehicles will also have to play their part in cutting CO² emissions. Renewable synthetic fuels can make the combustion process carbon-neutral. This is why, according to Denner, it would make more sense to offset such renewable synthetic fuels against fleet consumption, instead of tightening the CO2² rules for the automotive industry in a time of crisis.

In addition, Bosch wants to become a market leader in electromobility. To this end, the company will be investing roughly 100 million euros in the production of electrical powertrain systems at its plants in Eisenach and Hildesheim. Electrification is also making inroads in heating technology, for example in heating system modernization. “We predict a decade of electrification in the boiler room,” Denner said. With this in mind, Bosch is investing an additional 100 million euros in its heat-pump business and intends to expand its development work and double its market share.

Business year 2019: steadfast in a weak market environment

“Against the backdrop of a further weakening of the global economy and a 5.5 percent decline in automotive production, the Bosch Group held up well in 2019,” Asenkerschbaumer said. Thanks to a variety of successful products, sales totaled 77.7 billion euros, only 0.9 percent below the previous year’s level; adjusted for exchange-rate effects, they fell by 2.1 percent. The Bosch Group generated earnings from operations before interest and taxes (EBIT from operations) of 3.3 billion euros. This means it achieved an EBIT margin from operations of 4.2 percent. Excluding extraordinary positive effects arising especially from the divestment of the packaging machinery business, the margin was 3.5 percent.

“In addition to heavy upfront investments, the factors weighing on result were in particular the weak state of markets such as China and India, the further reduction in demand for diesel cars, and high restructuring costs, particularly in the mobility segment,” CFO Asenkerschbaumer said. With an equity ratio of 46 percent and cash flow of 9 percent of sales in 2019, Bosch’s financial situation is sound. Expenditure on research and development rose to 6.1 billion euros, or 7.8 percent of sales. At roughly 5 billion euros, capital expenditure was up slightly year on year.

Business year 2019: development by business sector

Despite the decline in global automotive production, the Mobility Solutions business sector generated sales of 46.8 billion euros. Revenues were 1.6 percent lower year on year, or 3.1 percent after adjusting for exchange-rate effects. This means that the Bosch sector with the highest sales outperformed global production volumes.

The EBIT margin from operations stood at 1.9 percent of sales. Business in the Consumer Goods business sector picked up during the year. Sales totaled 17.8 billion euros, which equates to a drop of 0.3 percent, or 0.8 percent after adjusting for exchange-rate effects. At 7.3 percent of sales, the EBIT margin from operations is lower year on year. The Industrial Technology business sector felt the effects of the declining machinery market, but still increased its sales by 0.7 percent to 7.5 billion euros; after adjusting for exchange-rate effects, this was a slight drop of 0.4 percent.

Excluding the non-recurring extraordinary effect from the sale of the Packaging Technology division, the EBIT margin from operations was 7 percent of sales. Revenues in the Energy and Building Technology business sector rose 1.5 percent to 5.6 billion euros, or by 0.8 percent after adjusting for exchange-rate effects. This equates to an EBIT margin from operations of 5.1 percent of sales.

Business year 2019: development by region

Bosch’s business performance varied from region to region in 2019. In Europe , sales were 40.8 billion euros, 1.4 percent down on the previous year, or an exchange rate-adjusted 1.2 percent. In North America , revenues increased by 5.9 percent (only 0.6 percent after adjusting for exchange-rate effects) to 13 billion euros. In South America , sales increased by 0.1 percent to 1.4 billion euros, but by 6 percent after adjusting for exchange-rate effects. Business in Asia Pacific (including Africa) reflected the collapse of automotive production in India and China: sales declined by 3.7 percent to 22.5 billion euros, an exchange rate-adjusted drop of 5.4 percent.

Headcount: one in five associates works in research and development

As of December 31, 2019, the Bosch Group employed 398,150 associates worldwide at just over 440 subsidiaries and regional companies in 60 countries. The main reason for the 2.9 percent year-on-year reduction in headcount is the sale of the Packaging Technology division. In total, some 72,600 specialists work in research and development at Bosch, almost 4,000 more than in the previous year. In 2019, the number of software developers in the company increased by more than 10 percent to roughly 30,000.

Key figures can be found here and in the 2019 annual report here.