CAT Pin Grabber Couplers boost productivity and reliability while keeping safety a priority

Cat pin grabber couplers bring a new level of productivity allowing the operator to change tools in a matter of seconds rather than minutes.

Excavators of similar sizes can share attachments. With the addition of the VB and HB sizes of pin grabber couplers, there is now a coupler for every size of excavator from the 311 – 390. VB and HB refer to linkage sizes.

Caterpillar classifies excavator fronts according to the “linkage family,” which is the size at the end of the stick. Pin grabber couplers are weighted to handle big payloads when added to a machine and bucket combination, without having to compromise on the bucket size.

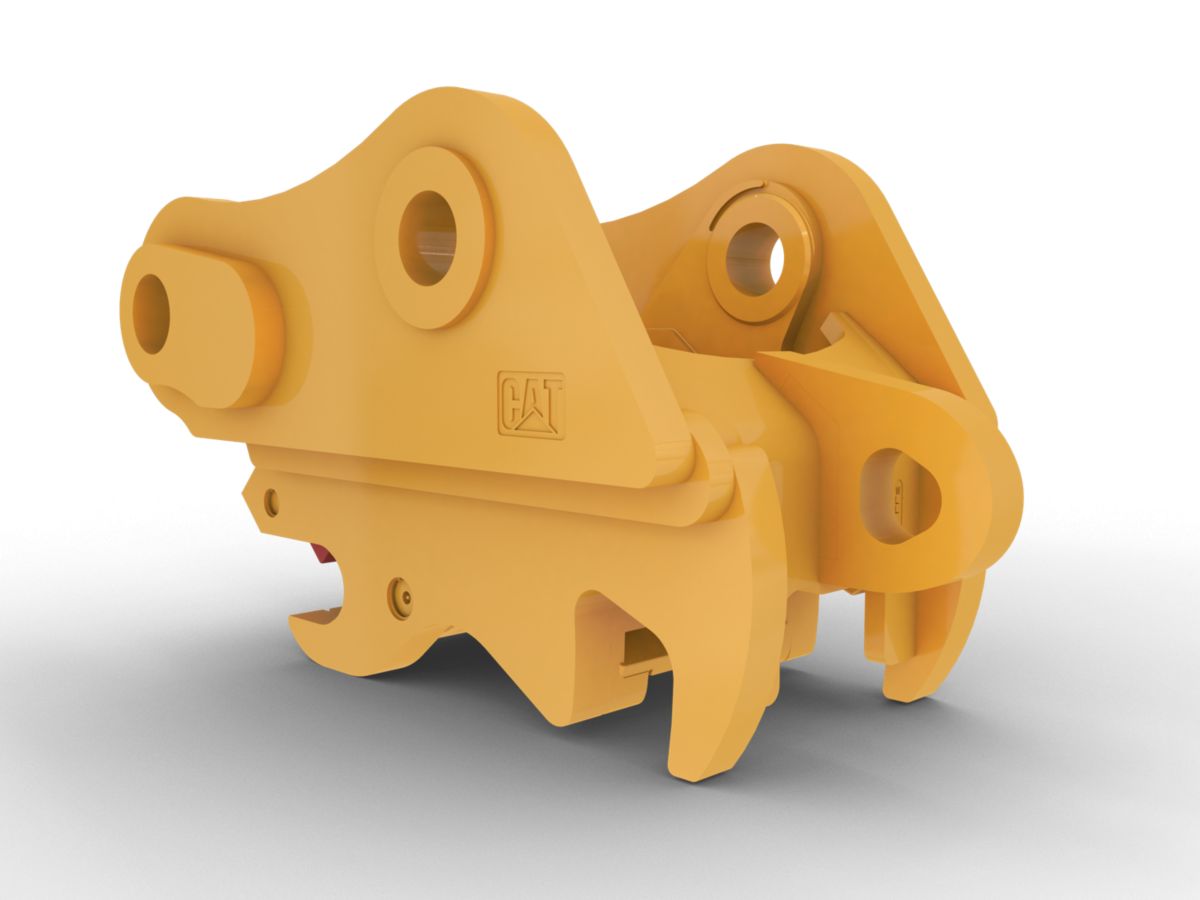

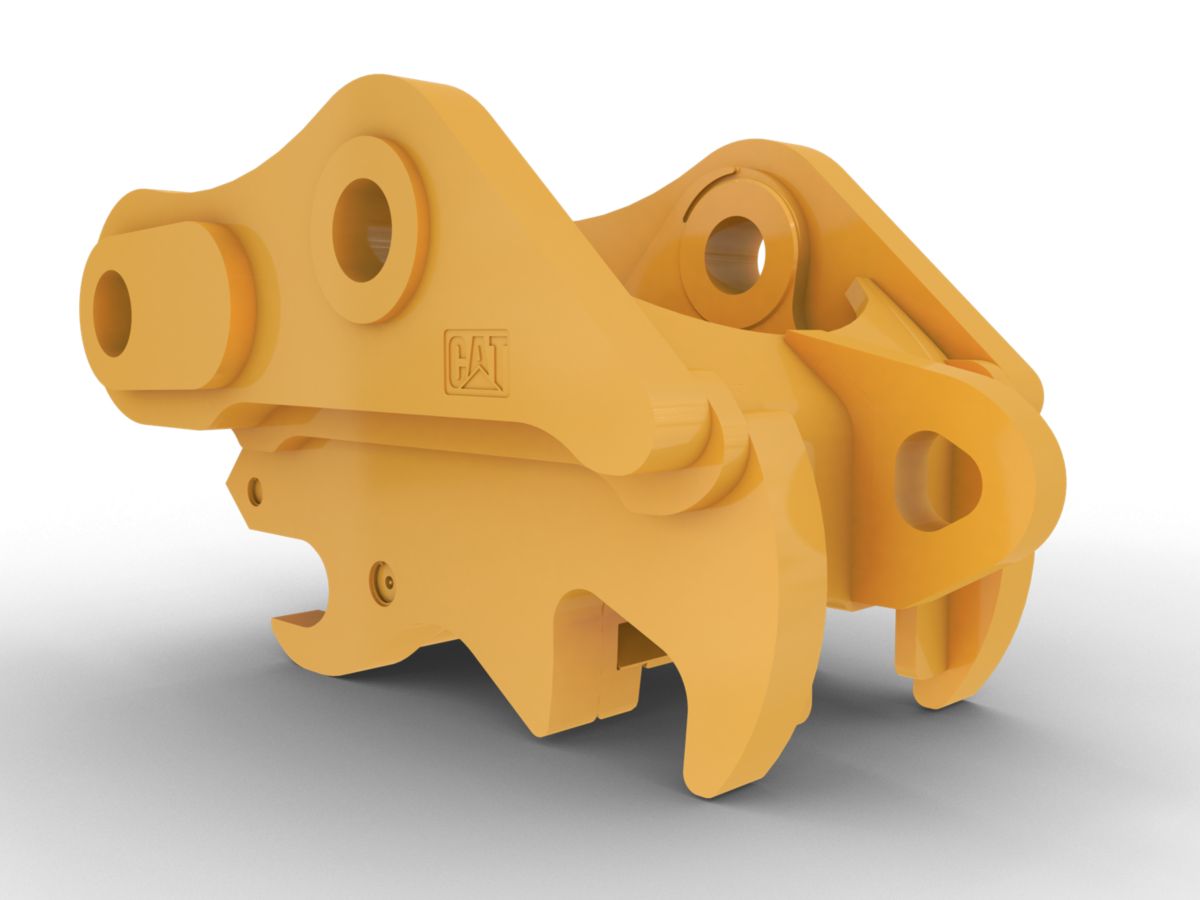

Pin grabber couplers feature a redundant locking system, ensuring attachments are secure to the coupler. The spring-loaded arms keep the latch closed, even in the event of a hydraulic pressure loss.

The shorter profile of the coupler helps keep the distance from the end of the machine’s stick to the tip of the bucket’s teeth compact, to maximize the amount of digging power you have with the addition of the coupler. The coupler frame’s cast pieces are made from abrasion-resistant steel to maintain the coupler’s durability over time.

The coupler has visual and audible cues for the operator to indicate it is secure to the attachment. The primary greasing block is the central greasing point for the whole coupler and is easily accessible at ground level.

Operating procedures for the pin grabbers are intuitive and simple to learn for operators of all experience levels. Adding the versatility of a pin grabber coupler allows you to switch from digging, grading, material handling, compacting soil, breaking rocks, and more with ease. Using the pin grabber coupler also gives you the ability to pick a bucket up in reverse position to clean out square corners.

Pin Grabber Coupler Specifications

| Linkage/ Model Name |

Minimum Carrier Weight | Maximum Carrier Weight | Coupler Weight | |

| Tons | Tons | kg | lb. | |

| 312 | 11 | 15 | 188 | 414 |

| 315 | 15 | 18 | 299 | 659 |

| B | 19 | 23 | 380 | 837 |

| CB-Trenching | 24 | 35 | 430 | 949 |

| CB | 24 | 35 | 465 | 1025 |

| DB-Narrow Profile | 30 | 40 | 624 | 1376 |

| DB | 30 | 40 | 621 | 1370 |

| TB-Trenching | 45 | 52 | 934 | 2060 |

| TB | 45 | 52 | 944 | 2082 |

| VB2 | 74 | 74 | 1244 | 2744 |

| HB2 | 90 | 95 | 1556 | 3430 |