Tatra Trucks celebrates 170 years as the oldest wheeled vehicle producer in the World

Tatra Trucks is one of the most famous Czech engineering companies and can be proud of the longest uninterrupted tradition of wheeled vehicle production in the world. In June, Tatra commemorated the 170th anniversary of its establishment.

Over the last few years, Tatra Trucks has already commemorated several historical milestones. In 2017, the company celebrated 120 years since the production of the first passenger car with an internal combustion engine, a year later Tatra Trucks saw 120 years since the creation of the first motor truck produced in Kopřivnice.

Last year, Tatra Trucks celebrated 100 years of the Tatra brand. And 2020 is associated with the 170th year of the company’s existence. However, Tatra´s trade name, status and owners have changed several times in the past, but the continued production of vehicles and the location of its factory has remained unchanged.

Versatile company and famous brand

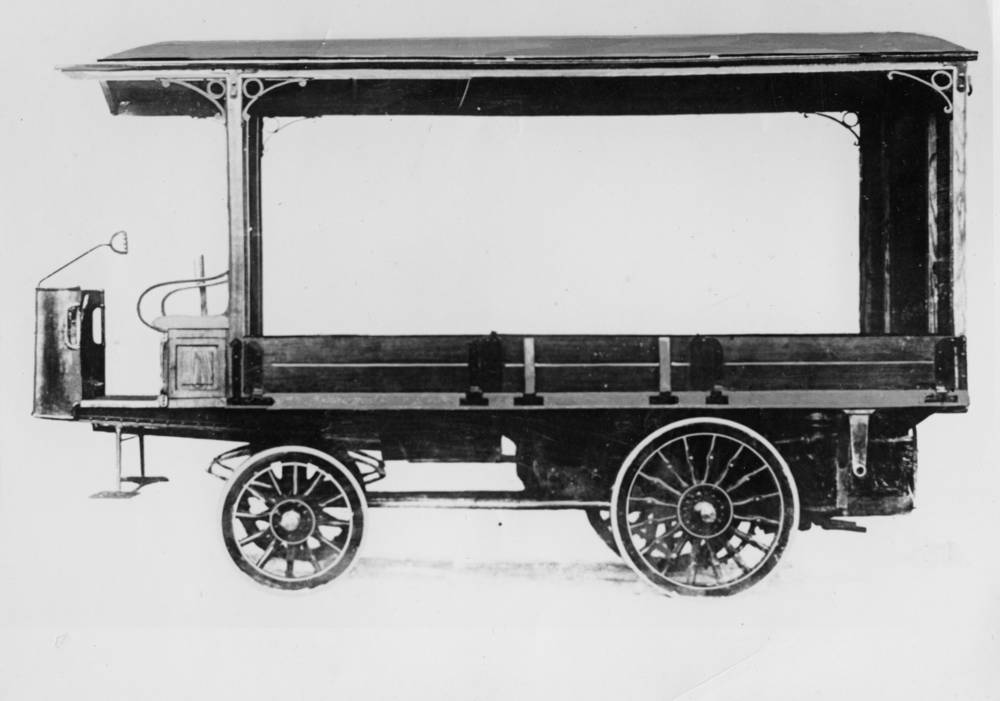

Tatra is one of the oldest vehicle manufacturers with a continuous history in the world, and one of the oldest manufacturers of trucks and passenger cars with internal combustion engines in history. In June 1850, the long history of the company known today as Tatra Trucks began to be written. At that time, the local native Ignác Šustala started his business in Kopřivnice. First, he manufactured carriages and chariots, later he started production of railway wagons. In 1897, the company created the first passenger car named Präsident. And a year later, the first motor truck drove out of the gates of the Kopřivnice factory.

One of the important milestones in the history of the Tatra company is the year 1923. The world-famous Tatra designer Hans Ledvinka then designed a unique chassis system known as the “Tatra concept”, which consists of a central load-carrying tube and axles with independently suspended swinging half-axles bolted together into a single unit. However, this solution has been successfully used until today.

The famous aerodynamic cars stand for yet another fundamental contribution by Tatra to the history of motoring before the Second World War. Tatra was the first in the world to mass-produce and sell passenger cars with aerodynamic bodies in the 1930s. These were the famous T 77, T 87 and T 97 models. However, Tatra also engaged in the production of trucks, mainly the widespread T 27, T 82, T 85 or T 72 types. These vehicles formed the backbone of the then Czechoslovak Army and were widely used in other countries too.

Tatra also continued to produce vehicles for railway transport, an example being the unique motor passenger M 290 Slovenská strela train, which has survived to this day and is currently undergoing a demanding renovation. However, Tatra also produced aeroplanes and aircraft engines, an example being the T 101/201 series sports aircraft, which were the direct predecessors of the famous Czechoslovak post-war aircraft Zlín Trenér series. The T 101 type even held the Czechoslovak record in terms of distance travelled, when its crew flew with it in 1938 to Khartoum in Sudan.

The main heavy trucks producer behind the Iron Curtain

After the Second World War, Tatra became the main manufacturer of heavy trucks for civil and military use in Czechoslovakia and supplied tens of thousands of vehicles to countries on almost all continents. The Tatra brand’s very good reputation was spread in dozens of countries by the T 111, T 138, T 148, T 813 and T 815 types. In addition, the production of limousines with an exceptional technical solution and original bodies continued. These were T 600 Tatraplán, T 603 or T 613 types. Tatra also built racing cars, which celebrated success on many racing tracks. Particularly noteworthy was T 607 Monopost built according to the specifications for F1 cars, or T 602 Sport or T 605. With racing variants of trucks, since 1980s, Tatra has been regularly and successfully participating in prestigious long-distance marathons, such as Rally Dakar, Silk Way Rally or Africa Eco Race.

The company entered the 1990s and the new economic environment with production based mainly on the well-known T 815 model line. At the beginning of that decade, the Tatra trademark was granted the status of a famous trademark by the Czech Industrial Property Office. The set of Tatra trademarks, today registered in more than a hundred countries around the world, thus forms an important part of Tatra Trucks’ value. The year of 1998 was another turning point since the production of passenger cars was terminated. Since then, the company has focused exclusively on trucks and special vehicles for the civilian and military use, which has become the cornerstone of its production and sales portfolio.

In the last decade of the 20th century, Tatra gradually began to penetrate to other markets, where customers required specific modifications and versions of vehicles. Thus, Tatra began to install engines and transmissions of foreign origin in its vehicles. The expansion into new markets was also helped by the deployment of Tatra vehicles in the colours of the Czechoslovak army and US army in the military operations Desert Shield and Desert Storm in Iraq the early 1990s. In the middle of that decade, the experience from the Middle East was reflected in the T 816 LIWA project, thanks to which Tatra won the first large contract outside the traditional markets. It was in this project that Tatra used foreign components such as engines and gearboxes according to customer requirements for the first time.

Important for the present of the Kopřivnice company was the year of 2004, when two completely new model lines saw the light of day – namely the T 815-7 (FORCE) and the T 810 (TACTIC). In the construction of both types, the designers based their plans on the requirements for modern military vehicles. Already for several years they have gradually become the backbone elements of the logistics capabilities of the Czech Army. However, they also found their important place in the civilian sphere, especially among firefighters and rescuers.

The most significant milestone in the operation of the Kopřivnice factory over the last decade was its takeover by Czech owners in 2013. The company was restructured and stabilized, and a connection to the leading Czech holdings – Czechoslovak Group and Promet Group – through their owners has been established. Thanks to this, Tatra brand is perceived by customers as a reliable business partner and the Czech public considers it part of the national heritage. This is evidenced, among other things, by regular placements in the first places in the public polls “The brand that Czechs are most proud of” and the “Traditional Czech brand”.

Specifics of Tatra vehicles

The main parts of the unique Tatra chassis system are central load-carrying tube and independent swinging half-axles bolted together into a single unit – this system is often described shortly as a “backbone tube or body-on-frame chassis”. In any case, the drivetrain shafts are situated in the central tube, and they are thus protected against external damaging effects. In addition to the drive shaft protection, this concept also offers other pros. Most importantly, the overall principle is inherently modular, and hence it can be used for relatively easy chassis construction with different number of axles. Naturally, trucks with four, six or eight wheels are most common, but Tatra also supplies its customers with the cars equipped with ten or twelve wheels. However, vehicles with sixteen wheels have also been produced. As a rule, such special vehicles are designed with all axles driven with several of them also steerable. These long Tatra trucks are nicknamed “dachshunds” or “centipedes”, and they are generally used as bogies for special applications in military and civilian sectors.

Naturally, the system with central backbone tube and swinging half-axles offers high throughput in difficult terrain, which ranks Tatra vehicles to the absolute top in global comparison. The advantages also include high stability when driving fast, even on corners, on slopes and with heavy loads. The chassis are designed with great resistance to extreme terrain and climatic conditions, which will be appreciated again by military and civilian customers who demand the full functionality of vehicles in all environments.

In addition to the chassis concept itself, Tatra also stands out by being eventually the only company in the World today to produce and install its air-cooled truck diesel engines (V8, V10 and V12 of Euro 3, 4 and 5 standards without any electronic injection systems) in series. Tatra Trucks prepares even air-cooled V8 and V12 engines of Euro 6 standard. At this time this solution is also one of the typical features of Tatra vehicles, although since long ago, Tatra Trucks company has offered its customers the option to use liquid-cooled units. Therefore many exported vehicles have Deutz, Cummins or PACCAR engines. However, some users still prefer air cooled units, for example the Czech Army or customers from the Central Europe, Australia, Russia etc.

In general, air-cooled engines can work well over a wider temperature range, making them more suitable for extreme temperature conditions. As a concrete example, we can mention excellent experiences with Tatra engines in racing trucks, traditionally participating in Rally Dakar (formerly Paris-Dakar Rally) or Czech and Slovak soldiers´ experiences from the Desert Shield and Desert Storm military operations. The Czech army´s Tatra trucks performed great because their engines maintained perfect functionality even in the desert. High temperatures simply didn´t affect the vehicles and the problem with dust and sand was solved by replacing the suction filters. The US Army was impressed and it bought a number of Tatra T 813 and T 815 trucks (especially in tractor and fuel tanker versions) from the defunct East German army and it operated them on its Middle East army bases.

Tatra Trucks and its vehicles today

At present, Tatra Trucks manufactures four standard model lines on three chassis platforms and cooperates with the companies of the Czechoslovak Group holding on the development of special military vehicles. The Tatra Phoenix model line has been a key element of the civil production program of heavy trucks since 2011. It uses a combination of the chassis of the Tatra concept and construction groups of renowned world manufacturers. Tatra Force is designed primarily for the armed forces, firefighters, and rescuers, but is also used in the mining and construction industries. The Tatra Tactic business line consists of medium-sized trucks with a ladder frame with rigid portal axles of Tatra´s own design and is designed primarily for military purposes. The Tatra Terra business line is a successor to the legendary T 815 model. The basis is again made of the original Tatra chassis, a modernized cab and air-cooled Tatra engines and Tatra gearboxes. Terra vehicles are designed primarily for firefighters and the construction industry.

Although throughout the existence of the Czechoslovakia Tatra trucks were exported mainly to the countries of the Eastern Bloc and to the “friendly” states of the Third World, they also managed to attract customers in the West. The promotion of the Kopřivnice trucks was also greatly helped by the aforementioned participation in the Rally Dakar (since 1986) and their deployment in Desert Shield and Desert Storm operations. Thanks to these, the Western armies’ representatives could also get acquainted with Tatra military vehicles. It is known that these vehicles left a great impression on them, as they proved to be fully comparable with everything produced by even the most advanced Western automakers.

Heavy trucks and chassis for special applications manufacturing is really a demanding and specific job, as evidenced by the fact that only a small number of states and companies have been capable of producing and supplying them. Few people realize that Czech Tatra Trucks company (and naturally the Czech Republic) belongs to a very small group of manufacturers who can produce heavy multi-axle bogies designed to fulfil special tasks and fit for use in very difficult external conditions. There are probably only ten such companies in the world today.

In the West, there is the American brand Oshkosh, which has long been an almost monopoly supplier of this category of vehicles to the US armed forces. It is also the German company MAN, which supplies military vehicles in cooperation with the Rheinmetall arms factory. In Europe, we can count probably the Swedish vehicle manufacturer Volvo and the Italian Iveco brand, which ends the list of suppliers from the NATO and EU countries. However, three other countries in the East produce special heavy vehicles. In Russia, these are the KAMAZ, BAZ and Ural automakers, while in Belarus the traditional MAZ brand and its former MZKT division have been operating (with MZKT specializing mainly in military vehicles manufacturing). In China there are two brands – Taian and Wanshan. There might be some other countries where companies are more or less able to meet the requirements (such as Sisu in Finland or KIA in South Korea), but their activities in this field are really limited. To add, the Indian company Tata has also been trying to produce its own heavy trucks, but the Indians themselves admit that their products are not as technically sophisticated as those from Tatra Trucks (whose products are used and widely appreciated in the Indian army).

Heavy trucks and their importance

Although it may not seem so, heavy trucks are of particular importance in both the armed forces and the civilian sector. For soldiers, these vehicles are one of the main elements of logistics, as they can transport loads of up to tens of tons on or off the road. The lay public most often envisions classic tarpaulins, but the fact is that since the 1980s, two different concepts have spread widely in the armies of developed nations. The first is the ISO standard container transporter and the second is the load handling system, which connects the hook loader and the platform, which can serve to clamp various loads. Tatra vehicles have been naturally also produced with these devices; in the Czech army, the second concept is represented by the Multilift system. In addition, large tankers are normally mounted on heavy trucks, so Tatra’s eight-wheel vehicles can handle more than 12,000 litres of water or fuel. Another important sub-field is the trailer and semi-trailer tractors, among them the so-called tank transporters, which pull low-loaders for tanks and other heavy vehicles with a total weight of over 100 tons.

Of course, various specialized bodies are also applied on heavy trucks chassis. The Tatra vehicles are used for example as recovery vehicles and mobile cranes, carriers of mobile folding and pontoon bridges, as well as weapon and sensor systems.

It is worth mentioning again the case of India, which installed its Prithvi ballistic missiles, BrahMos antiaircraft missiles, Akash anti-aircraft missile system, Pinaka artillery rocket launcher or several types of radars on licensed Tatra vehicles. We should not leave out that several arms manufacturers chose Tatra chassis as a platform for self-propelled howitzers construction.

Currently, there are at least five types of 155 mm calibre self-propelled howitzers constructed on the Tatra chassis: namely the Slovak Eva and Zuzana systems, the Israeli ATMOS type, the French Caesar system, the South African T5 Condor and finally the Indian MGS howitzer. In the distant past a famous self-propelled vz. 77 DANA howitzer was placed on the armoured Tatra chassis. However, its upgraded versions (such as Zuzana 2) are now offered by Slovakia. Tatra chassis also used with artillery rocket launchers (especially the RM-70 and its improved version of the RM-70 Vampire) and with a wide range of other specialized means.

Export success of Tatra Trucks company

Mentioning tree trunks transport reminds us that heavy trucks are also important in its use outside the military sphere, which also applies to Tatra trucks. It is the ability of the Kopřivnice truck manufacturer to produce very long chassis responding to customers’ requirements that has helped to build its strong position in certain specific fields requiring frequent movements of extremely large (usually long) types of cargo.

In addition to the above-mentioned logging and wood processing, it is mainly mining and mineral resources (especially oil and natural gas) processing, as the special long bogies help to transport parts of logging kits and oil and gas pipelines. Tatra trucks are also widely used and successful in construction industry, municipal services and, last but not least, firefighting.

Tatra Trucks is one of the highly successful producers of chassis for fire bodies, and although it is not well known to the wider public, even fire brigades in western states rely on vehicles from Kopřivnice. Tatra fire trucks were delivered also to the USA (e.g. National Parks Administration) and Australia, and to Israel. In general, these are countries that frequently fight forest fires, a situation in which Tatra off-road chassis can do its best.

When mentioning again the armed forces and corps sector, it should be noted that Tatra has won contracts in a number of countries after 1990 and several of the armies count on the Kopřivnice products as primary logistics assets and platforms for special applications. Next to the case of India, it is mainly Israel that at the time of the cooperation of Tatra Trucks company with the American company Terrex bought hundreds of trucks under the ATC brand. Next to freight transport, it also serves as a body carrier, including Rafael Spyder anti-aircraft missile systems. A thousand of Tatra T 816 vehicles were bought by the United Arab Emirates army, which operates flatbed trucks and tankers used for water and fuel.

Another interesting case is Brazil, which used Tatra chassis for its upgraded Astros II artillery rocket launchers. Tatra´s other important customers comprise of the armies and police forces of Afghanistan, Indonesia, Iraq, Jordan, Cyprus, Malaysia, Pakistan, Poland, Greece, Saudi Arabia (where Tatra trucks will also be assembled in near future) and Turkmenistan.

Finally, we can mention an interesting fact that Tatra (ATC brand) advanced to the final stage of the trucks supply tender procedure called LVSR (Logistic Vehicle System Replacement) for the US Marine Corps. The institution eventually chose the Oshkosh trucks, but it stated that Tatra products met all its requirements.

It is also worth noting that Tatra chassis are successfully used as a basis for various armoured vehicles. Already in the first half of the 1990s the Tatrapan vehicle (an armoured car on a six-wheel chassis) was developed in Slovakia. The vehicle has been constructed in several versions, e.g. as a commander´s or a medical one; later an eight-wheel model for transporting containers was designed and produced. Another armoured vehicle on Tatra chassis was named Wildcat: the four wheels vehicle was developed in Israel, where a six-wheeled armoured vehicle Karkadan also comes from. In Germany, the Drehtainer company offers armoured armour on Tatra chassis. Drehtainer has also produced a truly unusual application, the Mobile HEL Effector Container, which is equipped with a small laser that can be used for example to destroy drones.

The Czech SVOS company used Tatra chassis for the four-wheel and six-wheel VEGA armoured vehicles. And later, Tatra itself established close cooperation with the French Nexter company to develop a six-wheel TITUS armoured carrier. This vehicle has already been contracted from the Czech army, and the version for police is likely to be introduced by France. TITUS was tested, among others, in Albania or at Ivory Coast. Another interesting model is the four-wheel Patriot (or improved variant Patriot II) by Czech company Excalibur Army, created especially for the V4 countries. This broad spectre of armoured vehicles also illustrates the great potential of Tatra chassis.

Exceptional army vehicles are built in only a few countries

Tatra is one of the most famous Czech industrial brands, which is evidenced not only by its impressive long and rich history and still unique technical solutions of chassis and engines, but also by many impressive commercial achievements in a very specific and demanding industry of heavy trucks for special applications and extreme conditions construction. Only about ten manufacturers in the world can now supply similar vehicles, mostly from developed countries such as the USA, Germany, Russia and China. Using only a slight overstatement, this is a small and exclusive “club”, of which the Czech Republic is an undisputed and full member thanks to the Tatra Trucks company.

The importance of these vehicles should definitely not be underestimated, since it is not only an extremely important element of the logistics of today’s armies, but also platforms for the installation of various special-purpose superstructures, including weapon systems of strategic importance. For the general public, these trucks may not be as attractive as tanks or jets, but without the reliable support of a large fleet of heavy trucks, modern armed forces simply would not be able to function.

The quality of automobiles from Kopřivnice is also proven by an impressive range of military and civilian users, including a few very prestigious ones, such as the armies of Israel, India and the United Arab Emirates, fire brigades in the USA, Australia, Israel, Germany, Poland, Austria, and top mining and construction companies.

They are all clients who have to operate in demanding off-road and/or extreme climatic conditions and have specific requirements for the deployment of special superstructures or the transport of bulky loads – be it weapons systems, fire engines or industrial machines.

Tatra can meet these requirements mainly thanks to the unique and inherently modular concept of its chassis, which allows to build vehicles with four to sixteen wheels and capable of driving even in the most difficult terrain.

Finally, Tatra Trucks can be described as a company of strategic importance from the Czech point of view, as it provides to a large extent exceptional capability that are rare even on a global scale. The Czech Republic, as a small to medium-sized state, should deploy all available instruments on the international scene in order to be able to defend and assert its interests, which of course also include the supply of specific products, including military equipment.