Komatsu and Proterra collaborate on excavators electrification concepts

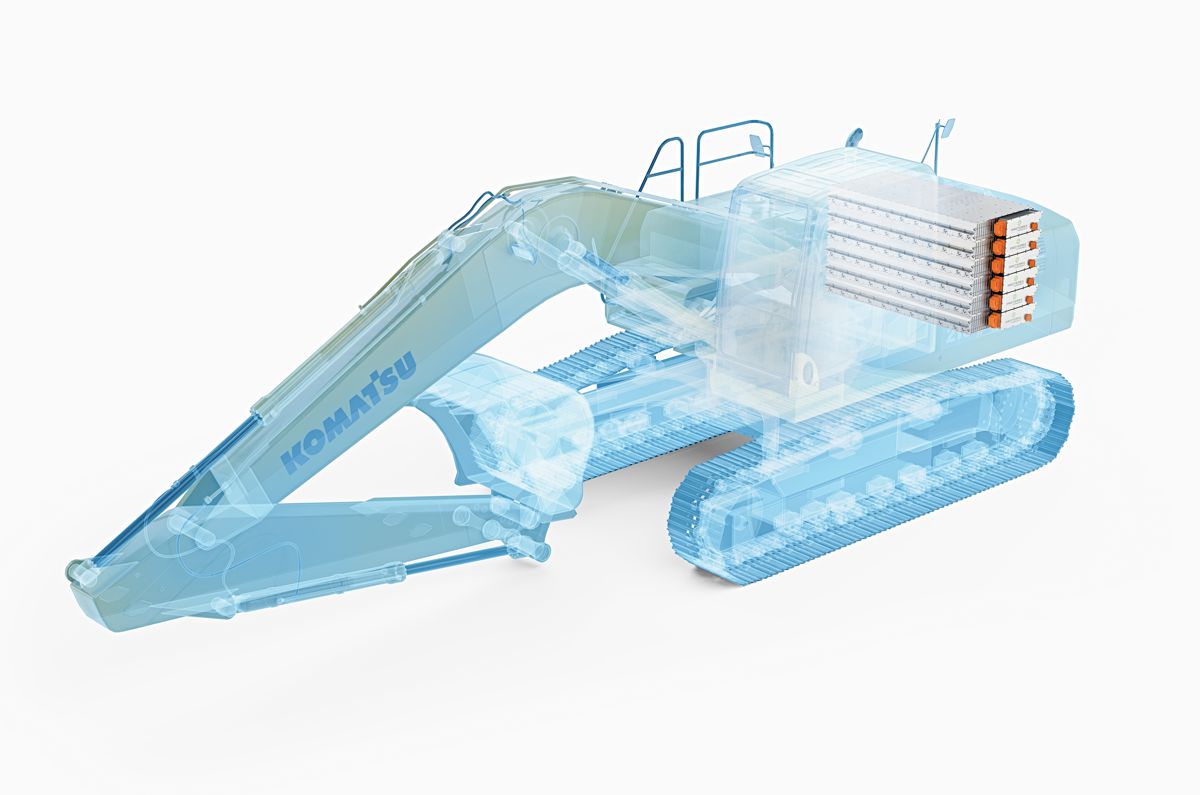

Komatsu has signed a collaboration agreement with Proterra Inc, who are based in the United States, to receive the supply of Proterra’s industry-leading battery systems with the aim of having Komatsu electrify its small and medium-sized hydraulic excavators.

Komatsu plans to advance the PoC (Proof of Concept) tests starting in 2021 and enter commercial production of its electric excavators in 2023 to 2024.

Proterra is a leader in commercial vehicle electrification technology. Through its Proterra Powered program, the company delivers its battery systems and electrification solutions to help heavy-duty and commercial vehicle manufacturers around the world electrify their vehicles.

In April 2020, Komatsu launched the PC30E-5 electric mini excavator. For its small and medium-sized models, Komatsu is going to receive high-performance batteries and peripherals which Proterra has developed with its state-of-the art technology accumulated over the years as North America’s leading manufacturer of electric transit vehicles. At the same time, Komatsu is going to collaborate with Proterra as one of its strategic partners of PoC tests. In the course of PoC tests, Proterra and Komatsu will develop an optimal battery system for small and medium-sized hydraulic excavators which require a large amount of output. Proterra’s flexible battery platform leverages industry-leading energy density and are highly customizable, an important advantage of their batteries that enables Komatsu to achieve optimal packaging of the batteries in excavators by combining them with Komatsu-developed key components. Komatsu also expects to generate additional benefits by integrating the partner’s technology with its own, such as integral technology for the development of machine bodies.

Komatsu has led the industry by developing products designed to contribute to mitigating environmental impact, as represented by its hybrid hydraulic excavators in 2008, which marked the world’s first hybrid construction equipment on the market, and its PC30E-5 electric mini excavator launched as domestic rental equipment.

Under its three-year mid-term management plan (FY2019 – FY2021), “DANTOTSU Value: FORWARD Together for Sustainable Growth”, Komatsu is working to achieve sustainable growth through a positive cycle of improving earnings and solving ESG issues. Komatsu also upholds the targets of reducing CO² emissions by 50% by 2030 from 2010. To this end, Komatsu is working to supply high-quality, high-efficiency products, service and solutions designed to mitigate environmental impact in response to climate change and improve safety.

As the concerns over climate change accelerate around the world, Komatsu is making full use of its accumulated technologies for hybrid construction equipment and electric mini excavators. Komatsu will also advance collaboration with its various strategic partners. In this manner, Komatsu will develop electric construction equipment which features zero exhaust gas and outstanding reduction of noise, while achieving excavation performance on par with engine-powered models.

While continuing its commitment to Quality and Reliability and working to maximize its corporate value, Komatsu is working to achieve safe, highly – productive, smart and clean workplaces of the future through DANTOTSU Value (ESG solutions and improvement of earnings through customer value creation).