Penetration grade bitumen: An Ideal Bitumen for Road Construction

Penetration grades are one of the most common types of bitumen for road construction. This type of bitumen is known for its durability and resistance to temperature changes; therefore, numerous oil refineries across the world have special plants for producing penetration grades.

Penetration grade bitumen is actually a broad category of bitumen that includes more than 5 subgrades, which are bitumen 30/40, 40/50, 50/70, 60/70, 80/100, and 100/120. Each subgrade of penetration bitumen has a number that shows its level of stiffness. In refineries, bitumen is tested by penetration method in which the expert perforates a standard needle in the bitumen and measure the speed of penetration to indicate the stiffness. A sample of bitumen 30/40 has a penetration of between 30 to 40 mm.

Among all grades of penetration bitumen, bitumen 60/70 is the most widely used in road construction. Also called the paving grade bitumen, this material works well in a wide range of temperatures (from -22 to +76). But this is not the only reason that bitumen 60/70 is popular in the world.

Bitumen 60/70: The Most Widely Used Grade of Penetration Bitumen

Penetration bitumen grade 60/70 is a moderate type of bitumen in terms of hardness, meaning it is not whether too hard nor too soft. Therefore, this grade of penetration bitumen resists temperature changes from -22 to +76. Accordingly, it is a perfect choice for road engineers in various regions, particularly Asia and South-East Africa.

In addition to the quality, bitumen pen grade 60/70 is the most basic form of bitumen, coming out of a vacuum distillation column; therefore, it requires no further processing. That’s why bitumen 60/70 is the basis of pricing of other types of bitumen. Indeed, major pricing benchmarks such as Argus Media and ICIS, consider bitumen 60/70 rate for evaluating the world’s bitumen price.

Properties of Penetration Grade Bitumen 60/70

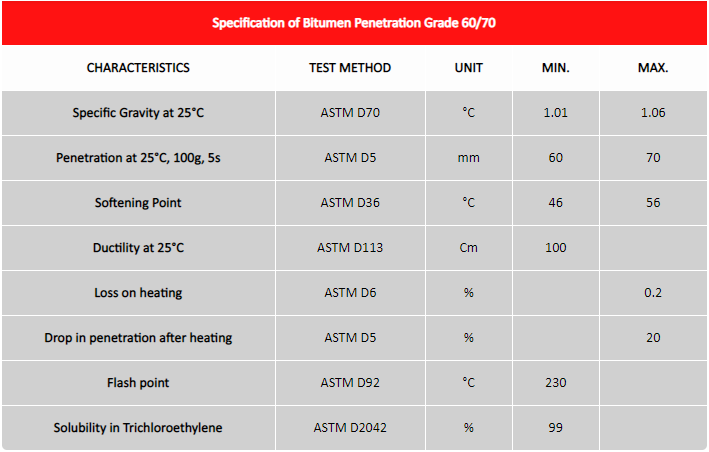

Each grade of bitumen has various properties, depending on the source (crude oil) and processing method. Therefore, all bitumen producers and suppliers are in charge of testing bitumen after production and providing buyers with specifications table. Bitumen 60/70 is not an exception. When this grade of bitumen is produced, the refiners send a sample of it to a laboratory, where various tests including penetration, viscosity, flash point, softening point, ductility and specific gravity are implemented on the sample.

The result of all these tests is essential in evaluating the quality of bitumen 60/70, however, the penetration level and softening point are more important. Penetration of bitumen 60/70 is between 60 to 70 mm, while the softening point is 46° C.

Here is bitumen 60/70 specification table by Infinity Galaxy, a global bitumen supplier:

What are the Applications of Penetration Bitumen 60/70?

The main application of bitumen grade 60/70 is in road construction. For paving roads in various regions, they blend bitumen 60/70 with aggregates to form hot mix asphalt. This grade of bitumen is suitable for roads with heavy traffic load. Bitumen 60/70 is popular in Asian and African countries, mainly because it is a cost-effective solution that reduces the expenses, without affecting the quality.

Bitumen 60/70 is also used for the production of polymer modified bitumen. Road engineers blend bitumen 60/70 with certain types of polymers to enhance the performance of bitumen in terms of elasticity, ductility, and the softening point.