GM accelerating an all-electric future with battery range and cost improvements

Today at a Washington Post Live virtual conference, General Motors President Mark Reuss provided more details about GM’s next-generation Ultium battery chemistry and announced a joint development agreement with lithium metal battery innovator SolidEnergy Systems.

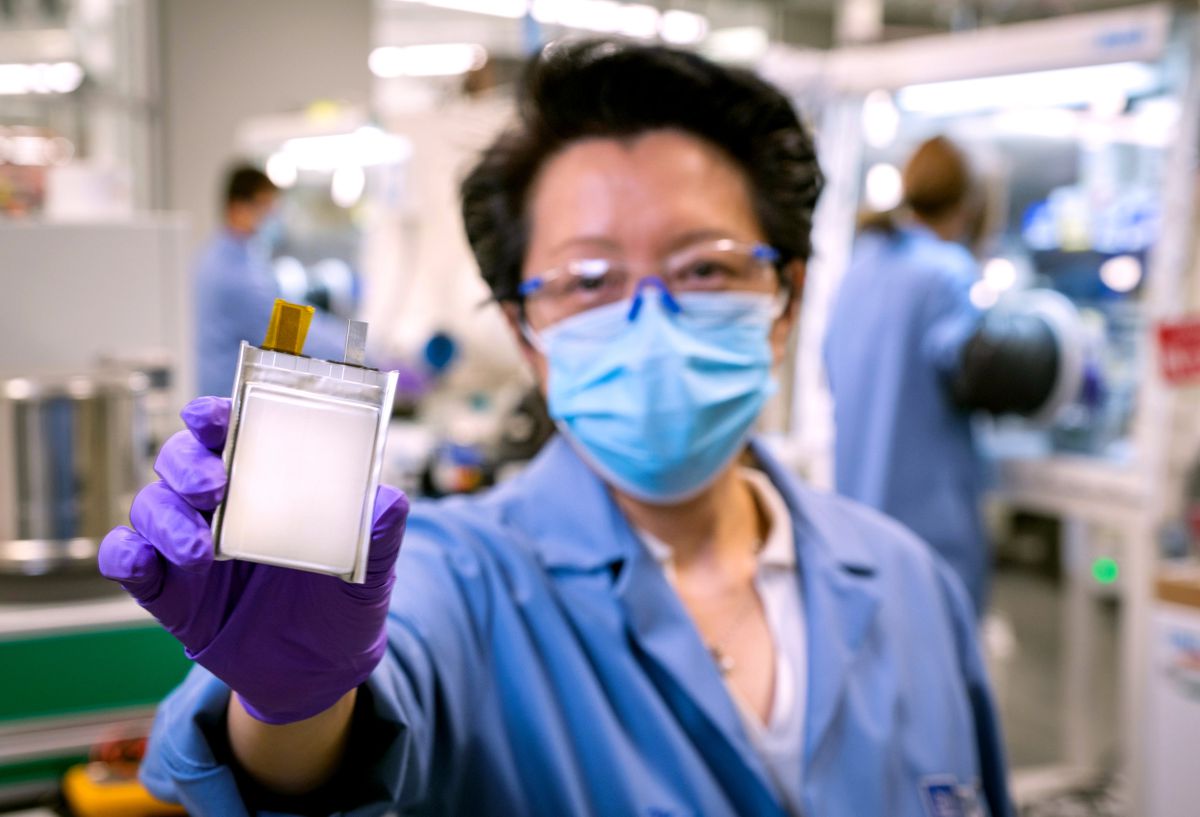

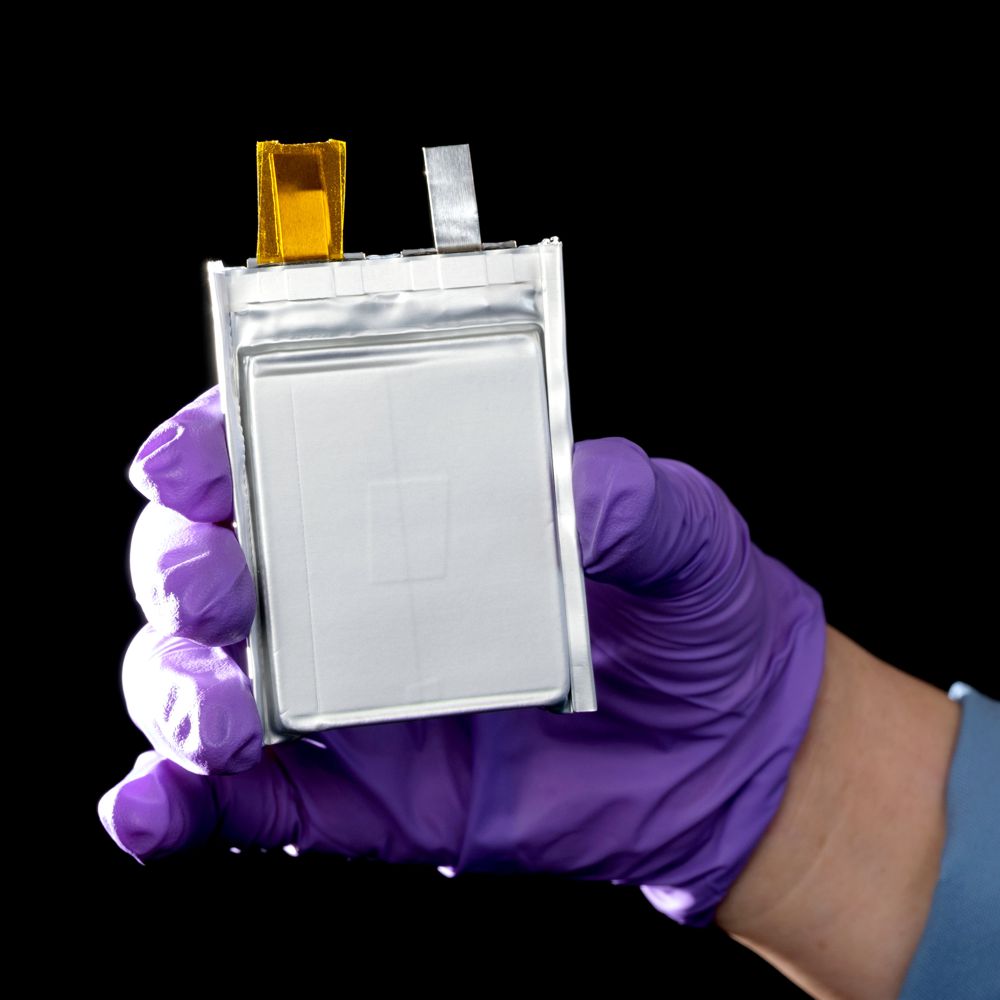

GM’s lithium metal battery with a protected anode will feature a combination of affordability, high performance and energy density. The initial prototype batteries have already completed 150,000 simulated test miles at research and development labs at GM’s Global Technical Center in Warren, Michigan, demonstrating real-world potential.

To accelerate Li-Metal battery commercialization, GM is working with several innovative companies and making investments that will allow the company to scale quickly.

GM Ventures was an early investor six years ago in SES, a research, development and manufacturing leader of Li-Metal technology and AI-powered battery management software to optimize performance and safety. The 2015 investment was the start of a close working relationship between SES and General Motors’ research and development organization.

Today’s joint development agreement is the next progression of that ongoing collaboration. As part of the agreement, GM and SES plan to build a manufacturing prototyping line in Woburn, Massachusetts, for a high-capacity, pre-production battery by 2023.

“Affordability and range are two major barriers to mass EV adoption,” said Reuss. “With this next-generation Ultium chemistry, we believe we’re on the cusp of a once-in-a-generation improvement in energy density and cost. There’s even more room to improve in both categories, and we intend to innovate faster than any other company in this space.”

The expected battery energy density increase could enable higher range in a similarly sized pack or comparable range in a smaller pack. The weight and space savings from smaller battery packs could help with vehicle lightweighting or create more room for additional technology.

Part of the foundation of GM and SES’ collaboration on Li-Metal prototype batteries is GM’s extensive lithium metal battery experience. The company’s expertise in this field has resulted in 49 patents granted and 45 patents pending. SES will also bring its own lithium metal intellectual property to the collaboration.

GM announces this rapid technical progress for possible use in future Ultium-based vehicles just one year after the reveal of the first-generation Ultium Platform. The first Ultium-based products are expected to go on sale later this year.

General Motors has made several announcements about rapidly driving toward its all-electric, zero-emissions future, including:

- GM revealed the heart of its EV strategy, a modular propulsion system and highly flexible global EV platform powered by proprietary Ultium batteries that will allow the company to compete for nearly every customer in the market today.

- GM committed more than $27 billion to EV and AV product development and plans to launch 30 EVs globally by the end of 2025, with more than two-thirds available in North America. Cadillac, GMC, Chevrolet and Buick will all be represented, with EVs at all price points for work, adventure, performance and family use.

- In January 2021, GM unveiled BrightDrop, a new business that aims to electrify and improve the delivery of goods and services by offering an ecosystem of electric first-to-last-mile products, software and services to help empower delivery and logistics companies to move goods more efficiently.

- GM’s zero-emissions technology will extend to fuel cells and the company announced it will supply its Hydrotec fuel cell power cubes to Navistar for use in its production model fuel cell electric vehicle – the International® RHTMTM Series.

- GM is investing $2 billion to transition the Spring Hill, Tennessee plant to build EVs, including Cadillac LYRIQ.

- GM announced that the Detroit-Hamtramck assembly plant, named Factory ZERO, will be GM’s first plant that is 100 percent devoted to electric vehicles and in fall 2021, will start building the new GMC HUMMER EV.

- In 2019, GM announced the formation of Ultium Cells LLC, a joint venture with LG Energy Solution to mass-produce battery cells in Ohio for future battery-electric vehicles. Construction is currently underway at the facility.