SENNEBOGEN Material Handler 870 Hybrid crawls in to action for BUS Bendorf

With over 6,000 operating hours, the SENNEBOGEN 870 Hybrid has already moved a lot in the inland port of Bendorf: Since 2017, the port colossus with crawler tracks has been on the quay of the company Bendorfer Umschlag- und Speditionsgesellschaft (BUS Bendorf) and is appreciated all along the line.

It works particularly efficiently and flexibly, thanks to significantly reduced energy consumption as well as the possibility to use numerous attachments to respond to the different requirements of the inland port business. The region on the banks of the Rhine is known for its local clay producers, and BUS Bendorf as a port of shipment helps these companies to transport goods from Bendorf to the rest of the world.

Bulk goods, general cargo, timber – everything is possible at BUS Bendorf. This is why stevedoring companies such as the Rhineland-Palatinate-based company are increasingly relying on material handlers to replace cranes on the quay, some of which are getting on in years. There are many reasons for this: the volume of cargo handled in inland ports has risen steadily in recent years, and more goods are being transported by water. It also becomes more difficult to purchase spare parts the older the existing crane models are. On top of that, depending on the material, a material handler completes two work cycles in the same time that a crane only manages one cycle.

It all comes down to the ease of use: With the help of quick couplers and their plug-and-play principle, drivers can adapt to a new material handling situation in no time. This is exactly how the port specialists at BUS Bendorf work: Sometimes a new ship can be found at the company’s 300-meter quay every day, which has to be loaded with clay but also various other bulk and general cargo such as excavated soil, wood, or big bags.

Every year, the company now handles around 300,000 t of material with the SENNEBOGEN 870 Hybrid, has a total quay length of 900 m, two docks where the 870 E is flexibly deployed, and 65,000 square meters of storage facilities.

Sophisticated machine design

In terms of mobility, the SENNEBOGEN 870 Hybrid wins in comparison: the harbour crane at BUS Bendorf was mounted on a movable rail gantry that allowed it to serve ships along the entire length of the 300 m long quay. On the other hand, it was also limited to this one travel path: operations on the second quay, some 500 m away, thus remained impossible. Since the routes there are limited to a maximum clearance height of 5 m, a sophisticated solution was needed that nevertheless provided the necessary reach and power of an 870 E Hybrid: The experts at SENNEBOGEN and the sales and service partner BRR reduced the height of the boom in the transport position to 4.80 m by implementing special kinematics.

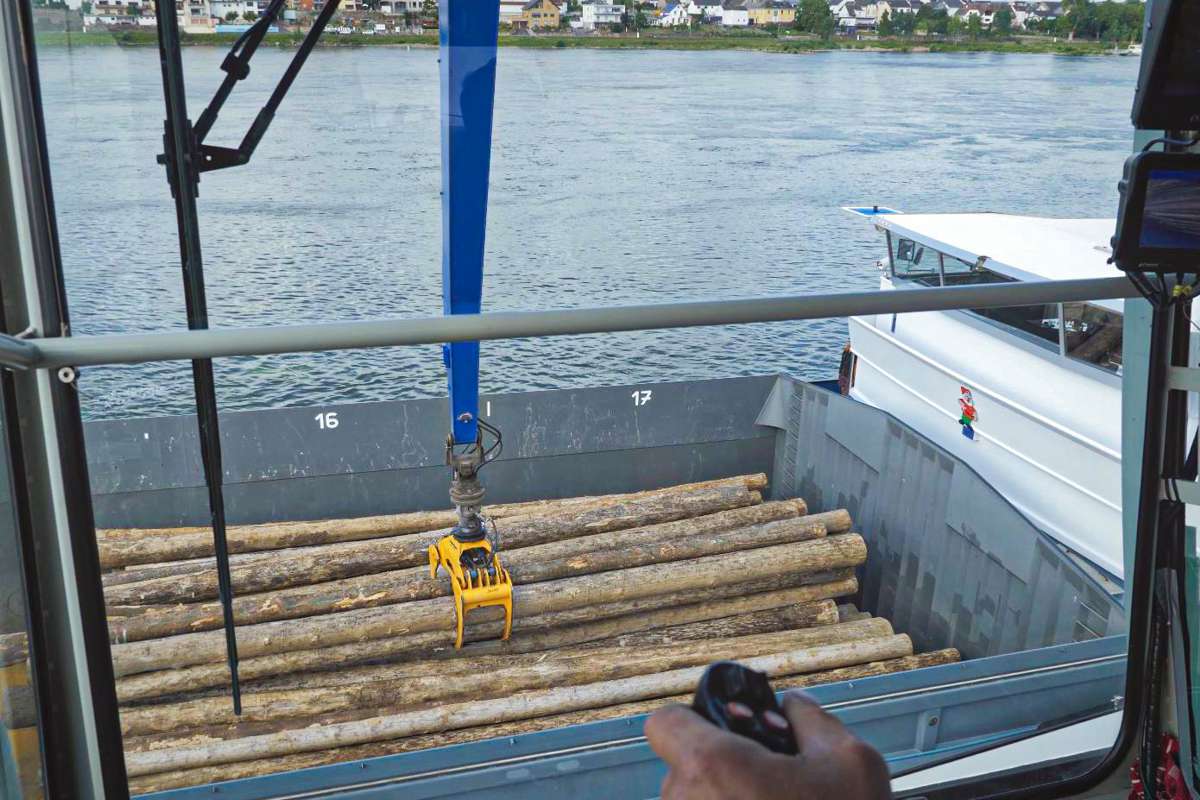

Visually, the material handler definitely stands out on the banks of the Rhine: Bright rapeseed yellow is used to decorate the uppercarriage, the boom shines in gentian blue in line with BUS Bendorf’s corporate colours. The 25 m long special port equipment offers even more reach depth: It is particularly advantageous at low water, because the quay wall in Bendorf is preceded by a sloping embankment, ships may therefore have to berth 10 to 12 m away from the wall and still need to be loaded. The 25 m long special port equipment offers even more reach depth: With the wide, force-transmitting contact surface of the heavy crawler undercarriage, the material handler is always securely positioned on the quay, even at full outreach and with large loads in the grab.

For Managing Director Markus Stock, however, the decisive feature of the material handler is the SENNEBOGEN Green Hybrid System: “Thanks to the recuperation energy, fuel consumption is significantly reduced and we can now work even more efficiently. I personally appreciate that the machine works very reliably and is virtually always available. Thanks to the user-friendly electrical system, we can also do some of the work ourselves with specific guidance!”

Operator precision

The recipe for a born heavy equipment operator is to start early: “I sat on heavy machinery for the first time when I was just 3 years old, because my father used to work in a quarry. So I’d like to say that I’ve been in almost every kind of excavator – but I’ve never driven a better machine than the SENNEBOGEN 870 Hybrid,” reports proud operator Maik Hannöver who is working for BUS Bendorf. He spends many hours in the ergonomically designed seat of the SENNEBOGEN Mastercab and adds, “And it is a very comfortable place for me to work in!”