DokaXact wins CTBUH Innovation Award of Excellence

Doka has been awarded an Innovation Award of Excellence by the CTBUH 2021 Awards Programme for its DokaXact system. The award will be presented during the CTBUH 2021 Conference, which will be held virtually for the first time from 18-20 May.

The Council on Tall Buildings and Urban Habitat (CTBUH) is the world-leading resource for professionals focused on the inception, design, construction, and operation of tall buildings and future cities. The annual CTBUH Tall + Urban Innovation Conference looks at the world’s best innovations in tall buildings, urban spaces, building technology and construction methods and rewards them with awards in over 20 categories. Doka won an Innovation Award of Excellence for the DokaXact system and competes for the Overall Category Winner at the CTBUH 2021 Conference in May.

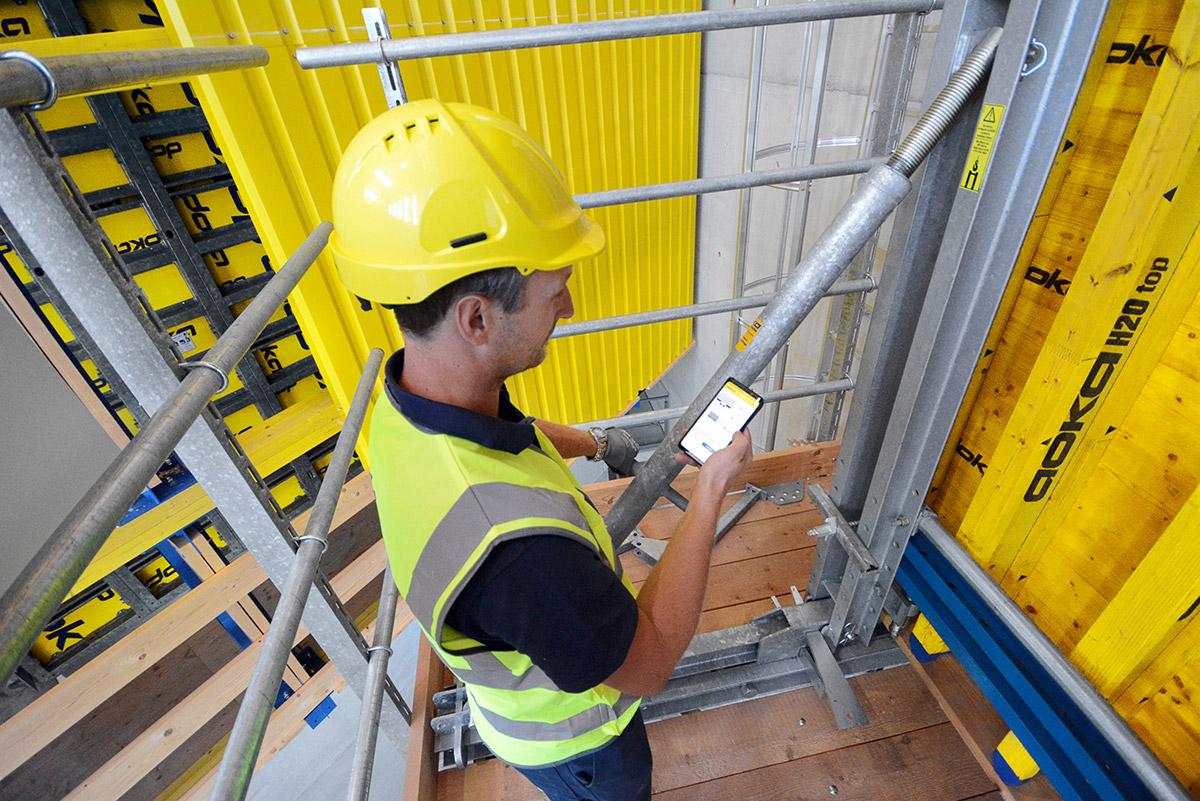

DokaXact is an interactive sensor-based solution that enables the accurate positioning of wall formwork for vertical structures at a new level. It is a tool for surveyors and crews that allows site teams to quickly and precisely plumb and align wall formwork used with Doka climbing systems. The system was used first on Elephant Park in London and brought significant benefits, according to Wojciech Jawor, Surveyor, AJ Morrisroe & Sons Ltd.

“The DokaXact system supported me ideally in my daily work as a surveyor. I did not need to be present for aligning and plumbing the formwork elements. However, I was able to monitor the site progress from anywhere at any time. This gave me more time and flexibility for other surveying processes on-site.”

The expectations on the precision of built in-situ concrete structures continue to rise – for example, those for the installation of vertical transport systems or the connection of prefabricated concrete elements to the in-situ concrete core.

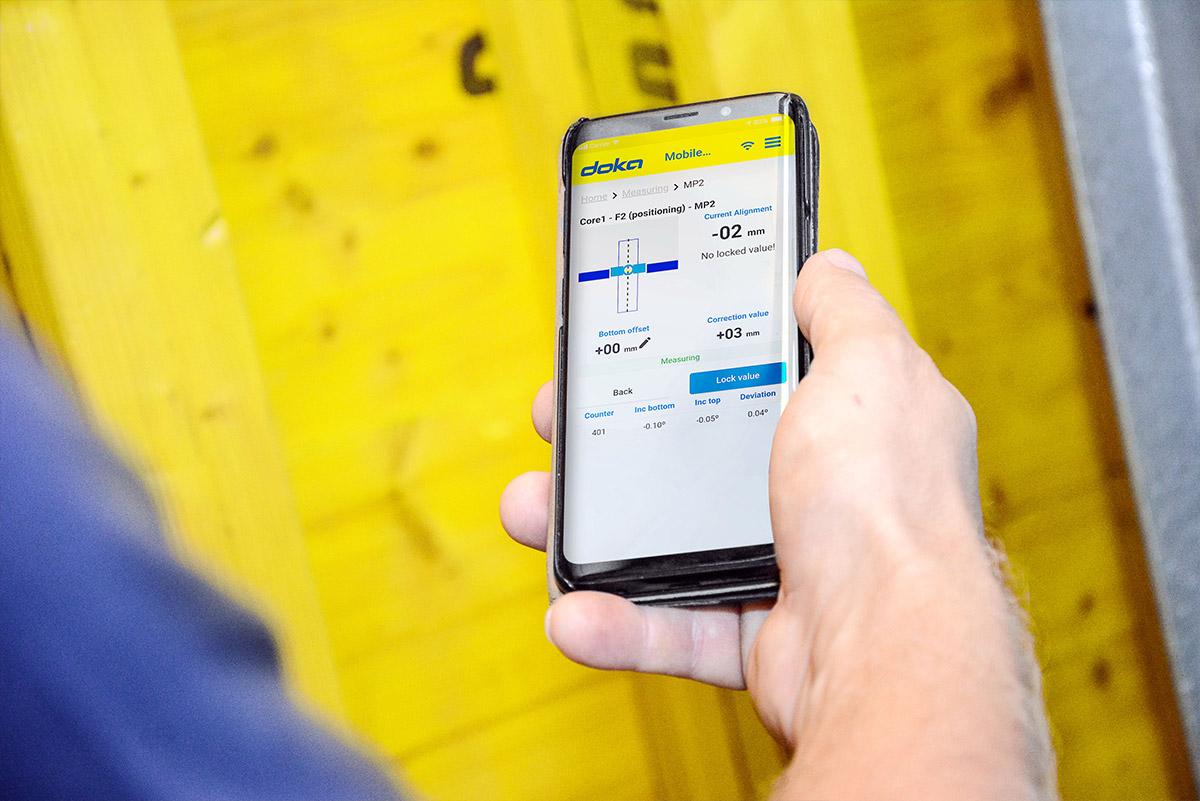

DokaXact supports this with its high system accuracy of ± 2mm. The system consists of multiple sensors attached to defined surveying points of the wall formwork, which communicate wirelessly with a centralised processing unit.

A useful tool for increasing productivity

DokaXact assists and speeds up the surveying process before pouring. The site crew can align the formwork prior to the final position check by app assistance with predefined routines.

This reduces the amount of re-measurements by the surveyor and possible formwork adjustments that would be required. The overall forming time will be accelerated.

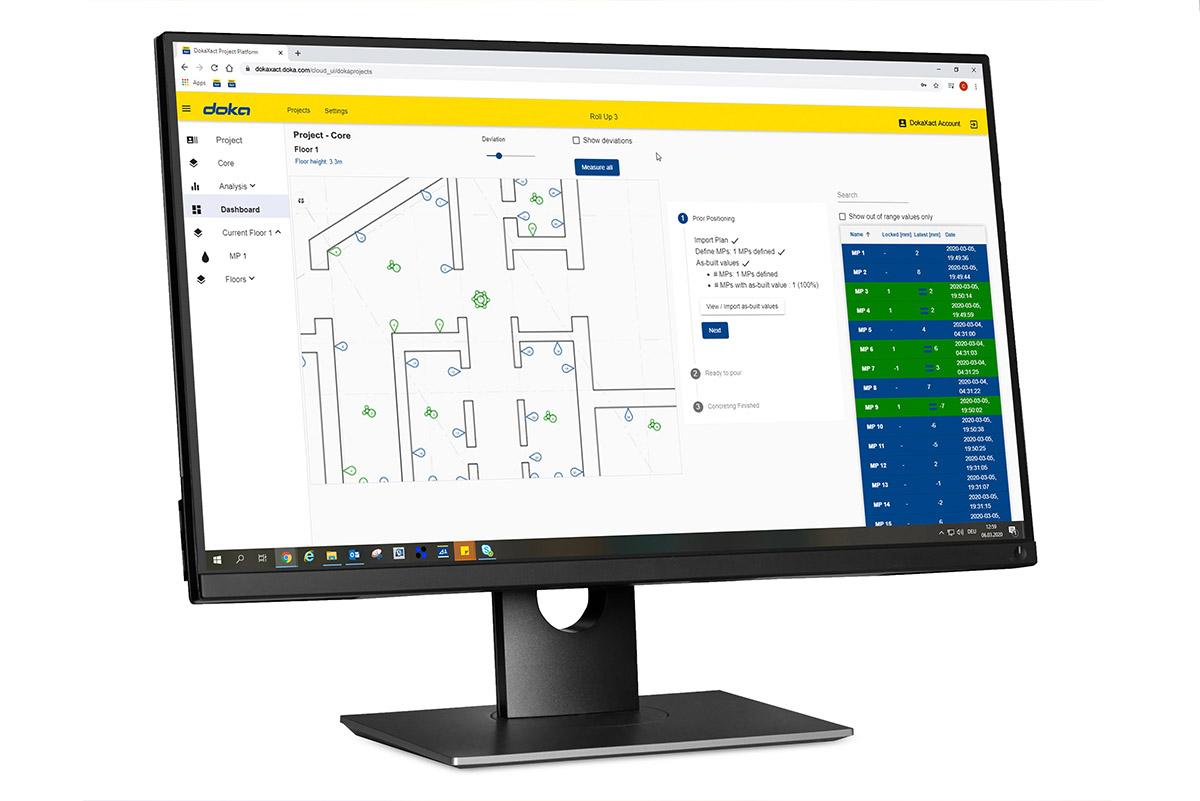

Knowing the actual position of the formwork elements from anywhere at any time

DokaXact provides a quality assurance tool to built more accurately. With the live monitoring function, potential movements of the formwork can be made visible at all phases – from the positioning to the pouring process.

Site managers are now able to observe their building tolerances 24/7 from anywhere, allowing preventative actions to be taken in order to avoid cost intensive reworks after pouring.

Learning from the past for the future

On the DokaXact web portal, the data are made accessible for site managers and surveying engineers. The portal is the reporting, monitoring and analysing platform to improve and optimise the routines and processes for the cycle to come. By creating efficient operations, increased productivity and higher quality of execution, the DokaXact system becomes a valuable tool for site crews, construction managers, and surveyors working on construction jobs.

“DokaXact can help build in-situ concrete high-rise cores, bridge piers and pylons more accurately in combination with faster forming times. The actual position of the formwork is known at all times of the working cycle – starting from the positioning of the formwork to installing the reinforcement, pouring and curing of concrete. DokaXact digitalises the positioning and monitoring of the entire wall formwork by transforming the traditional formwork survey method,” says Dan Zvinca, Business Developer DokaXact.

Award-winning

In addition to the Innovation Award of Excellence in the CTBUH 2021 Awards, DokaXact has received the 2020 Innovation Award of Excellence from Building Enclosure, 3rd place 2019 Matexpo Innovation Award, and was 2019 bauma Innovation Award Finalist.