Createc develops robotic solution to make nuclear waste decommissioning safer

An innovative robotic solution to mapping and segmenting different levels of nuclear waste without the need to put humans into a hazardous radioactive environment has been proven by a pioneering company.

Createc is behind some of the world’s most advanced technologies in robotics and computer imaging and is well-known for finding solutions to some of the world’s most complex industrial challenges.

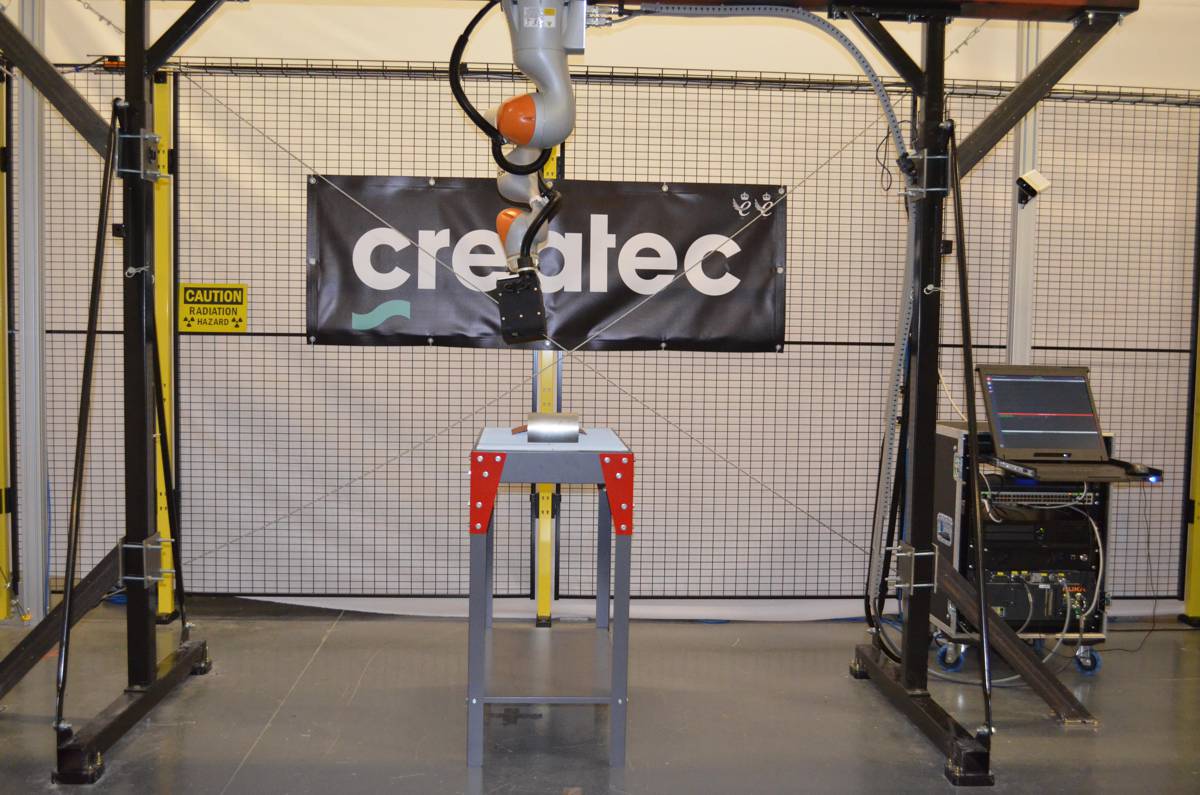

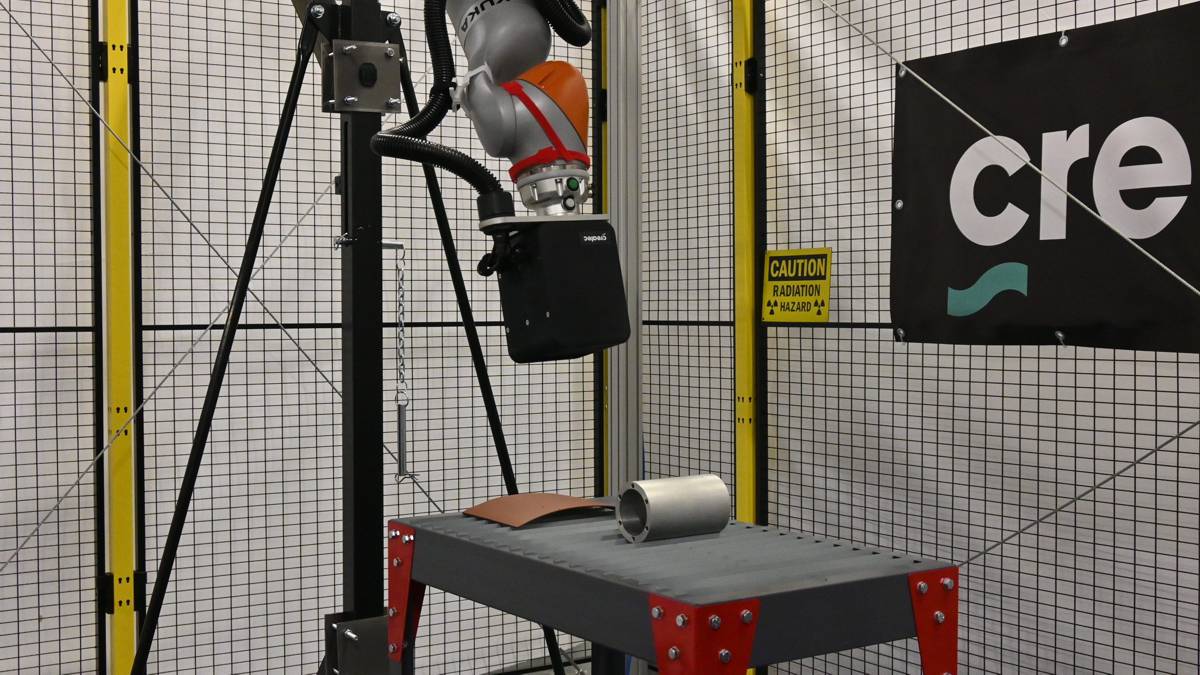

Createc’s Automated Nuclear Detection Cell (AND-C) innovation responds to the challenge of removing nuclear workers from hazardous environments by providing a system that can remotely scan items for radioactive contamination and then automatically remove the contamination.

Createc’s technology, developed as part of an Innovate UK project, involves an AND-C sensor pack being deployed on a robotic arm.

The sensor scans the contaminated item and the 3D radiation contamination map is transferred directly to the robotic system to guide the arm to the precise location and remove the contamination.

David Clark, Createc’s operations director, said: “The AND-C system allows remote radioactive decontamination without requiring operators to work inside a hazardous nuclear environment.

“In many nuclear decommissioning facilities, a decontamination cell is used to process transport containers on site so that they can be sentenced to low level waste.

“This is labour intensive work which needs to be carried out using complex PPE and sometimes air-fed suits.

“This involves multiple operational teams as well as support staff and radiation protection staff.

“Combining Createc’s proven technology for radiation mapping with nuclear robotic arms means the precise location of the contamination can be identified and removed without having to put nuclear workers into this hazardous environment.

“It means operations can be carried out more safely, sooner and also at less financial cost.”

Identifying different levels of nuclear waste in this way will result in significant financial savings as it will mean low level waste will not be sent to intermediate level waste facilities unnecessarily.

In the UK alone the lifetime disposal costs of nuclear waste are estimated at £18billion equating to £50,000 per cubic metre of intermediate level waste and £7,500 of per cubic metre of low-level waste.

Will Newsom, Createc’s head of nuclear engineering, said: “There is a strong driver to ensure that waste is accurately assayed and as much as possible of the waste is put into the appropriate low-level storage.

“AND-C provides an intelligent approach to nuclear waste management by assessing the activity of the waste item to a very high level of accuracy.”

The process starts with the waste items being moved into the AND-C cell. The end of the robot uses the AND-C sensor pack which can navigate the object and avoid collision. The scan generates a point cloud and radiometric data is collected.

Createc’s tried and tested N-Visage® technology, commercially deployed across the world including at Sellafield in the UK, and extensively at the Fukushima Daiichi site in Japan, is then used to estimate the source distribution of the contamination of the object’s surface.

A 3D model combined with radiometric data is then used to plan how waste will be dismantled, improving the effectiveness and cost of decontamination.

Will said the technology answers three main challenges for the nuclear decommissioning industry, namely can it:

- potentially reduce the amount of nuclear waste going into higher categories by removing assessment pessimisms.

- remove people from the danger of the assessment of that waste.

- use digital tools to improve the workflow of the nuclear industry as a whole.

- The modular approach of the technology and its use of Createc Robotics’ innovative Iris platform means the whole system is flexible and agile and can be easily modified depending on the task.

Etienne Hocquard, Createc’s head of robotics, said: “As long as the robot can reach the area it can be surveyed.”

Createc is widely recognised in the nuclear industry for its success in innovation and problem solving. It has pioneered some of the latest technology which is being deployed around the world to provide accurate, and readily available, radiological information.

Employing almost 30 people in a diverse, agile team of technical experts from fields such as Computer Vision, Robotics, Nuclear Measurement and Optics, Createc can efficiently build prototype systems and develop them into full products.

Createc, which provides solutions to the civil nuclear, defence, rail, marine, and security sectors, is also the holder of two Queen’s Awards, with awards for Innovation and for International Trade.