Evonik and Farsoon collaborate on high temperature 3D printing materials

The specialty chemicals company Evonik and China’s largest SLS 3D printer manufacturer Farsoon are strengthening their collaboration in powder-based 3D printing.

Both companies aim to open up market access to new large-scale industrial applications in the higher temperature range. Evonik is contributing its expertise in polymer-based 3D printing materials and Farsoon is bringing its expertise in powder-based 3D printers to the joint effort.

As part of this, the specialty chemicals company has already successfully tested the ready-to-use polymer powder INFINAM® PA 6005 P (polyamide 613) with higher temperature resistance on Farsoon’s ST252P and HT403P series machines. The development of new formulations is underway.

INFINAM® – Materials for infinite 3D applications

“Close collaboration between material and machine manufacturers is essential to open up new 3D applications. The results of our test series are clear: INFINAM® PA 6005 P with its higher melting point of 215 °C can not only be excellently processed on Farsoon’s ST252P and HT403P machines, but also recycled. We used our synergies to develop a market-ready system solution,” says Wolfgang Diekmann, Director Research, Development & Innovation Additive Manufacturing at Evonik.

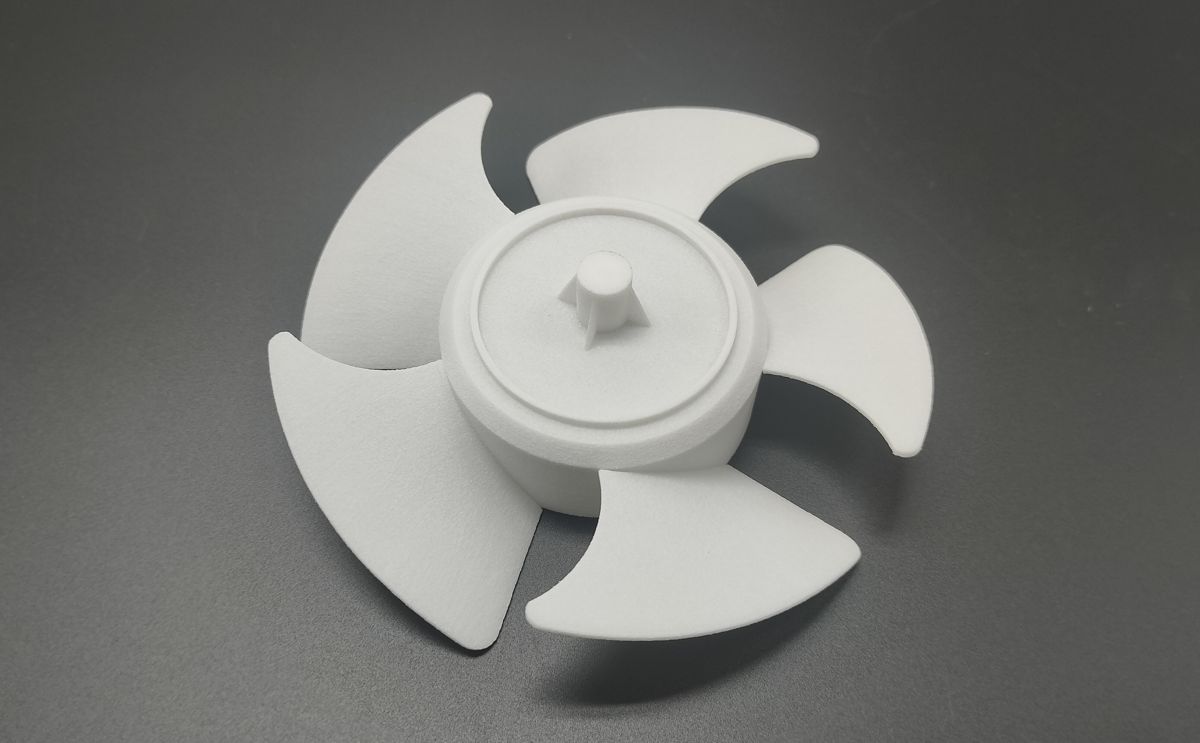

INFINAM® PA 6005 P is a high-performance powder from Evonik’s polyamide 6 series. The material has high mechanical strength, high chemical and temperature resistance, and low water absorption – below 3 percent. The latter has a positive effect on processability in the 3D printing process and the dimensional stability of the printed component. The objects printed from the PA 613 powder material impress with high stiffness and mechanical stability, even in thin-walled constructions.

Technology synergies open up new applications

Farsoon’s machines offer configuration options that can reach process chamber temperatures of up to 220 °C (HT) or up to 280 °C (ST). Improved thermal controls, temperature-protected components and open parameters provide customers with the ability to process high-performance polymers such as Evonik’s PA 613 with excellence. The machines are equipped with high-speed scanners and powerful lasers. The high productivity of component production increasingly enables series applications.

“We are very pleased to be able to offer further opportunities to the additive manufacturing market by proactively supporting new applications in the higher temperature range,” says Dr. Dirk Simon, Managing Director of Farsoon Europe GmbH and responsible for polymer material topics in Farsoon’s Global Management Team. “The excellent compatibility of our SLS machines with Evonik’s polymer powders, as well as the very interesting property profile of PA 613 components, form important foundations for our customers’ market success.”

Polymer powders with excellent flow properties

The new polymer powder in Evonik’s polyamide 6 series with its nearly round grain shape enables excellent flowability and application properties, making it suitable for all powder-based 3D printing technologies. A proprietary procedure is employed to produce the high-temperature material at the company’s Marl site.

Evonik bundles its expertise in 3D printing in the groups’ additive manufacturing innovation growth field. The strategic focus is on the development and production of new high-performance materials for all major polymer-based 3D printing technologies. In this context, Evonik has organized its product range under the new INFINAM® brand and is driving forward 3D printing as a large-scale industrial manufacturing technology along the entire value chain.