Highways England trials Graphene solutions to transform road construction materials

Graphene, a material only one atom thick, could be used to prolong the life of roads across the country. If successful, Highways England trials using this high-tech product could see the operational life of key road features extended by a number of years, reducing the frequency of roadworks and making journeys for road users smoother and more reliable.

In a world-first project, Highways England is working with the Graphene Engineering Innovation Centre (GEIC) at The University of Manchester and Pavement Testing Services (PTS) to see how graphene can be used in four different areas; bitumen, asphalt, steel safety barriers and road markings.

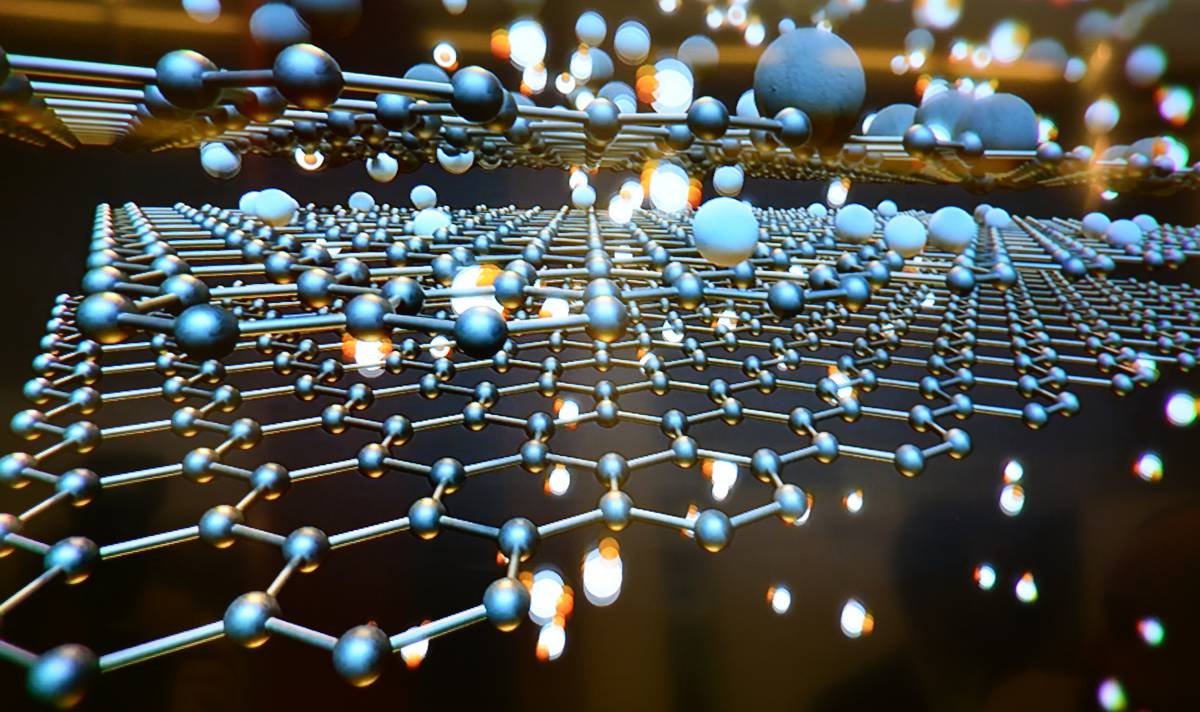

Graphene is the name for a single sheet of carbon atoms, arranged in a honeycomb pattern. It is the building block of graphite — pencil lead — and is an incredibly strong, conductive and flexible material. It can be used in a wide range of applications, from aerospace engineering to digital electronics and biomedicine.

Graeme Watt, Asset Needs Manager for Highways England in Yorkshire and the North East, said: “This is an exciting time for Highways England. We are constantly striving to improve the journeys of our customers and graphene has real potential to do that.

“Its benefits are industry-changing. It’s stronger than steel and adding it to other materials can turn them into super materials. From what we’ve seen so far, it could make some of our assets last significantly longer and be used in maintenance to prevent the failure of existing assets.

“Laboratory trials have been a success and on-site trials later this summer will be a world first use of graphene in road production, which enforces our commitment to innovation and helps to push the industry towards more carbon-friendly maintenance with longer-lasting solutions which we all benefit from.

“As an industry, asset failure has become a way of life and is accepted. We want to challenge that acceptance, extend the life of assets and make their lifecycle more predictable.

“The research with the GEIC is a great example of how we are making that happen and we are looking forward to seeing the results on our network.”

Trials have seen graphene added to cement and recycled road materials

Highways England currently uses a specialist machine called a Cold In-Situ Recycler, which breaks up the existing road surface, mixes it with bitumen and then re-lays the road in a single operation. This removes the need to import hot materials from quarries, increases the speed at which we can reconstruct carriageways, reducing the timescales for roadworks, improving safety and significantly reducing carbon footprint.

In August, planned recycling works using this machine on the A1 in the North East will see graphene added to the bitumen to increase the durability of the product and further extend the life of the carriageway.

Highways England is also working with the GEIC to extend the life of existing surfacings, using graphene to reduce the ageing effects caused by ultraviolet light to further extend the life and durability of its roads.

Research will also examine if the life of steel safety barriers can be extended with a protective coating of graphene and if white lines can be made to last as long as the road surface they are added to.

Adding graphene to white lines could prolong their life to last as long as the road surface

Road markings wear down and become less reflective over time, with most needing to be replaced every two to four years. The road surface itself lasts much longer but reapplying the lines can damage that surface.

If graphene can prolong the life of the marking, making it last as long as the road surface, there will be even less disruption for drivers. It would also reduce the number of times roadworkers would need to be out on high-speed roads.

James Baker, CEO of Graphene@Manchester, said: “We are excited to be working with Highways England and their supply chain to see how we can use graphene and 2D materials to enhance the road network with a number of potential future products and applications.

“The partnership with Highways England as a growing Tier 2 partner of the GEIC into a number of key projects and demonstrator activities can help accelerate and re-risk some key developments for future road infrastructure and in support of the sustainability challenges and drive towards net-zero.”

Earlier this month Highways England published its new innovation and research strategy outlining how innovation, research and technology are critical to developing the knowledge, tools and solutions to respond to a changing future. Projects like the graphene research are an example of our how the government company is working with industry partners to innovate and create a safer, greener and digital future.

Visit the Highways England website for more information on the world-first graphene project.