Liebherr will showcase their latest innovations at MINExpo 2021

Liebherr will showcase its latest innovative equipment, technology, and services for the mining industry at MINExpo International® in Las Vegas, USA, from September 13–15, 2021.

Covering a total area of more than 28,000 sq. ft (2,600m2), Liebherr booth #7627 will present advancements from its Mining, Mobile Cranes, and Components product segments.

At MINExpo 2021, Liebherr Mining will display the R 9150 Generation 7 (G7) 130t / 143 ton excavator, the next generation of excavator cab from the recently announced R 9600 G8, the PR 776 70t / 77 ton mining dozer with LiReCon teleoperation system, the newly introduced T 274 305t / 336 tons haul truck along with a display from Liebherr Components, and the LRT 1090-2.1 90t / 100 ton rough terrain crane from Liebherr Mobile Cranes. New developments and exciting announcements will be presented from Liebherr Mining’s new technology portfolio, as well as the pathway forward into low and zero emission mining.

Attendees will be able to interact with new technologies through a VR booth, and discover Liebherr’s technology at the daily masterclasses held with Liebherr experts. Fans and customers who cannot attend in person will not miss out; all exhibits, announcements, and showcases from the expo will also be delivered on Liebherr’s website and social media channels.

R 9150 G7, R 9200 G7, and R 9600 G8

Liebherr will introduce three new excavators at MINExpo: the R 9150 Generation 7 (machine showcased on the booth), the R 9200 Generation 7, and the brand-new R 9600 Generation 8 (cabin showcased on the booth). These three machines establish the new naming strategy based on technology levels for Liebherr machines. This approach aims to achieve a common and long-term logic within the Earthmoving and Mining product ranges in a clear manner.

All three excavators are now equipped with the latest innovations including Liebherr Power Efficiency, Assistance Systems, and Bucket Filling Assistant.

LPE (Liebherr Power Efficiency) is a specific engine and hydraulic management system, which drastically reduces fuel consumption by up to 20%. Assistance Systems are advanced on-board applications designed to support the operator to become more efficient through analytics and actionable insights. Assistance Systems will be presented physically in the R 9600’s cabin and on tablets displayed on the booth.

Visitors can also discover the Assistance Systems through an immersive experience in the VR (virtual reality) area. BFA (Bucket Filling Assistant) is the first automation product of the Liebherr hydraulic excavator portfolio, and allows the operator to realise the bucket filling process automatically.

T 274 mining truck

Liebherr has recently extended its product offering with the T 274, a class-leading 305t / 336 tons haul truck. This new truck bridges the gap between the T 284 and T 264. Designed and adapted from years of experience in mining truck development, the T 274 is a true 305 tonne machine that provides fast cycle times, higher production rates, low fuel consumption, and a low cost per tonne.

This new truck follows the same base design as the T 284, benefitting from its decades of field experience. Operators and technicians can expect to experience first-class comfort and safety while driving and servicing this truck. A wide range of options are available including the Liebherr Trolley Assist System and Liebherr Autonomy Kit.

PR 776 dozer and LiReCon teleoperation system

Liebherr will also showcase its flagship mining dozer the PR 776 Litronic, which delivers best-in-class efficiency.

The machine will be on display together with the new LiReCon Liebherr teleoperation system. LiReCon (Liebherr Remote Control) provides additional comfort and safety for operators in tough mining applications.

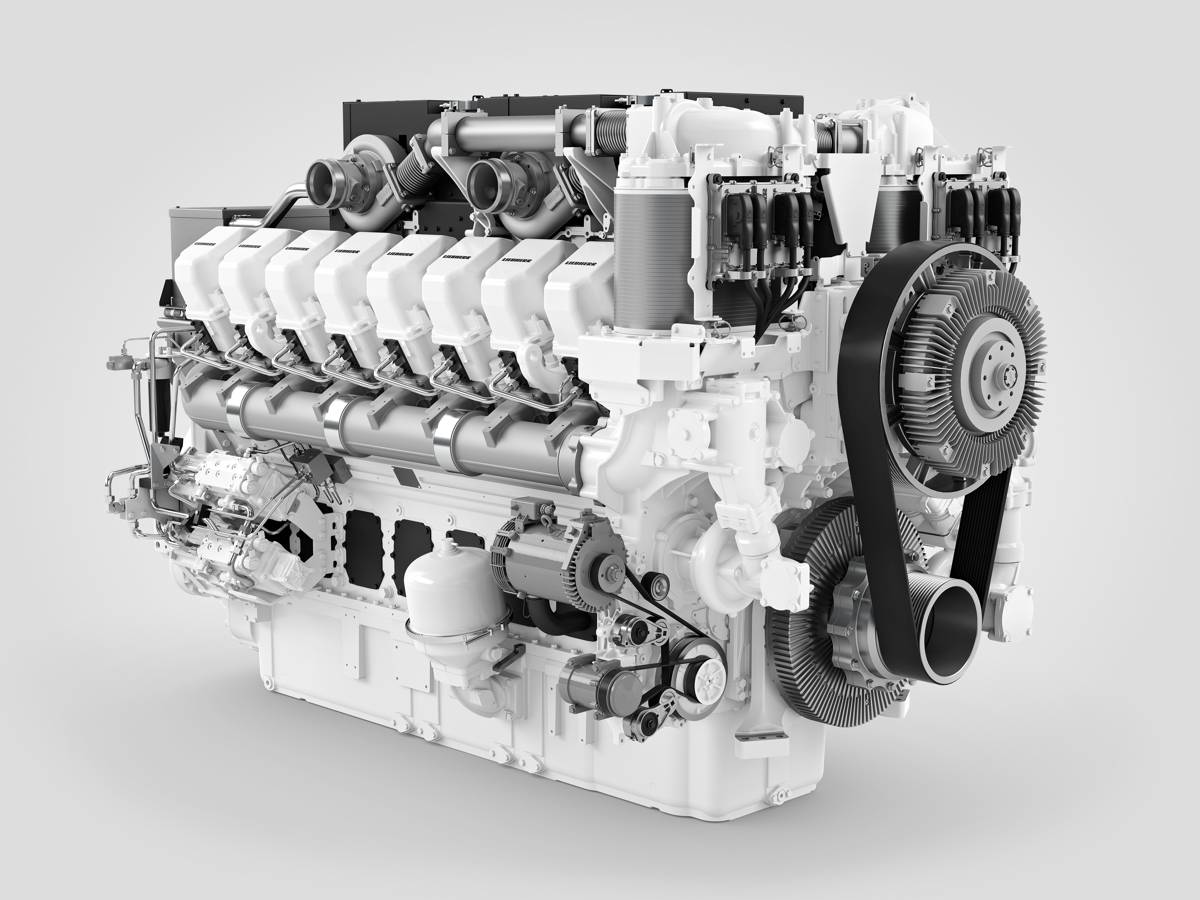

Liebherr components and D98 diesel engine series

Liebherr components for mining applications will also feature at MINExpo. Among the components is the D98 diesel engine series, which is available for both Liebherr and other mining equipment manufacturers, for new and repowered machines.

The V-16 engine of the D98 family, the D9816, is not only on display at the booth but is also at the heart of the exhibited T 274 haul truck. This marks the beginning of the integration of the D98 series into Liebherr machines.

LRT 1090-2.1 rough terrain crane

The LRT 1090-2.1 90t / 100 tons rough terrain crane is designed to deliver the highest safety level. It is fitted as standard with an outrigger monitor which automatically detects the support status and includes the crane control system. It is also delivered as standard with the VarioBase® variable support base which enhances flexibility on site and increases the crane’s lifting capacity.

The LRT 1090-2.1 features a 47m / 154ft telescopic boom. Its telescoping system consists of a two-stage hydraulic cylinder with a rope extension mechanism. The boom can be extended easily with two telescoping modes, strong or long. The extension mechanism has been designed for high telescoping lifting capacities.

Innovative Mining Technology Product portfolio

Liebherr will present the world premiere of its brand new Mining Technology Product portfolio at MINExpo. This will demonstrate the company’s interoperable and scalable approach to their equipment, technology, and service product offerings.

This portfolio consisting of Liebherr’s Assistance Systems, Machine Automation, and Digital Service products will provide customers with flexible scope of supply solutions to increase safety and asset operational effectiveness.

Together, these products will support operator’s performance, optimise diagnostic processes and automate machine functions, whilst integrating machine data and OEM expertise within the customers chosen technology landscapes.

Zero Emission Program

Liebherr strives for long-term sustainable solutions, investigating different options centred on safety, cost, reliability, maintainability, and flexibility. Liebherr Mining already offers a range of solutions to help customers achieve low emissions, including our full range of electric excavators, and soon-to-be full range of trolley-capable mining trucks.

Further to this, Liebherr Mining has a clear vision and roadmap to expand its current offering to achieve low fossil fuel solutions in 2022, along with fossil fuel free solutions for the majority of applications by 2030.

At MINExpo, strategic partnerships with energy and infrastructure providers will be announced, alongside the roadmap for Liebherr to provide these solutions to our customers.