SOCOTEC explores the management of Asbestos Risks in the Railway Industry

Asbestos containing materials (ACMs) have been in widespread use in the rail network in the past, within buildings, rolling stock (trains) and the rail infrastructure.

As with any other sector, it is essential that sufficient information regarding the potential location of asbestos is recorded prior to any demolition, repair or refurbishment works taking place. With this in mind, it is equally important for rail workers to know what to do if an ACM is disturbed, while also being aware of the health risks associated with the inhalation of asbestos fibres.

The general rule of thumb is that ACMs will only pose a risk to health if they are disturbed or damaged. If they are in good condition and are left untouched, they should not pose any danger. However, if a building or location has no known information about whether or not it contains asbestos, it must be assumed to contain the fibrous mineral, with action immediately taken to determine if this is the case.

Where might asbestos be located on rail premises/rolling stock?

It is possible that any train, station or depot constructed before the year 2000 may contain asbestos. In buildings, it is often found in ceiling tiles, insulation boards, vinyl floor tiles, roof sheeting and pipe lagging, and railway buildings are no exception. Its fire resistant and insulating properties also made it a highly popular material for the construction and maintenance of trains. Located predominantly within engine rooms, brake pad linings and piston cylinders, asbestos in its varying forms has also been discovered in such materials as:

- Millboards in catering vehicles, exhaust pipes in engines/locomotives and skirting within seating partitions (chrysotile – white asbestos)

- Paste under locomotive frames and insulating boards (amosite – brown asbestos)

- Sprayed fibres on the sides, roofs, ends and floors of rail vehicles (crocidolite – blue asbestos)

- Textiles and arc chutes – many old rolling stock still incorporate ACMs within textiles and arc chutes, the latter of which are used in circuit breakers within all types of electrical equipment to insulate and protect circuits from shorting

- Asbestos cement – the fibres in asbestos cement products are firmly bound in the material and will only be released if the product is subjected to breakage. Asbestos cement products which are used externally will weather slowly, so risk of exposure from fibre release is low if the material is left undisturbed

- Ballast – can often have some asbestos contamination present as a result of material dropping from trains/stations and trackside debris coming into contact with the tracks. When ballast is recycled, an opportunity arises to check the material and remove any contamination prior to it being used after processing.

How can you identify ACMs on rolling stock/rail premises?

Where a material or component is suspected of containing asbestos, the item must be treated as an ACM until proven otherwise. This will then be identified by a qualified person as an ACM or non ACM, and where appropriate, the type of asbestos will also be determined. There are a range of materials incorporated within rolling stock and related infrastructure that could potentially contain asbestos, with sampling and analysis serving as the definitive way to decipher whether the fibrous mineral is present. Some components are identified as being asbestos-free by stamping or having two ‘v’ notches cut into the material.

Does legislation concerning asbestos management affect my rail organisation?

It is a legal requirement to determine whether asbestos is present or reasonably expected to be present within a building or on rolling stock, with failure to comply having serious consequences for owners and contractors. Regulation 4 of the Control of Asbestos Regulations (CAR) 2012 requires duty holders of non-domestic premises to identify, locate and manage the risk from asbestos, and this includes railway lineside structures, railway vehicles, train stations, depots and other buildings constructed for rail-related purposes.

In order to comply with CAR 2012, duty holders must:

- Locate ACMs throughout the premises/on rolling stock and assess the risk posed to health

- Keep accurate, up-to-date records about the location/s of ACMs

- Ensure that anyone who might disturb asbestos is aware of its location and condition

- Develop a risk management plan and update regularly.

While the REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) Regulations 2013 prohibits the use of asbestos in building fabrics, the Office of Rail Regulation issued an Exemption Certificate in 2014, which has eased restrictions against the marketing and use of a railway vehicle or component containing ACMs where there is no risk to workers and the general public. To meet the requirements of Schedule 5A of REACH, the following actions are required:

- Confirm that the vehicle/component was in service or installed before January 2005

- Take reasonable steps to remove ACMs, unless removal could increase the risk to health

- Ensure risks to health are properly assessed and controlled

- Keep accurate records about the location of ACMs in the vehicle or component.

Finally, the Waste Classification WM3 2015 provides guidance on best practice when controlling waste that is suspected to contain asbestos. To meet the guidelines, rail organisations should assess whether asbestos is present in the form of free dispersible fibres, as well as whether it makes up more than 0.1% of waste. They should then take steps to safely dispose of waste where high levels of asbestos fibres have been detected.

What is the recommended course of action upon discovering or disturbing ACMs?

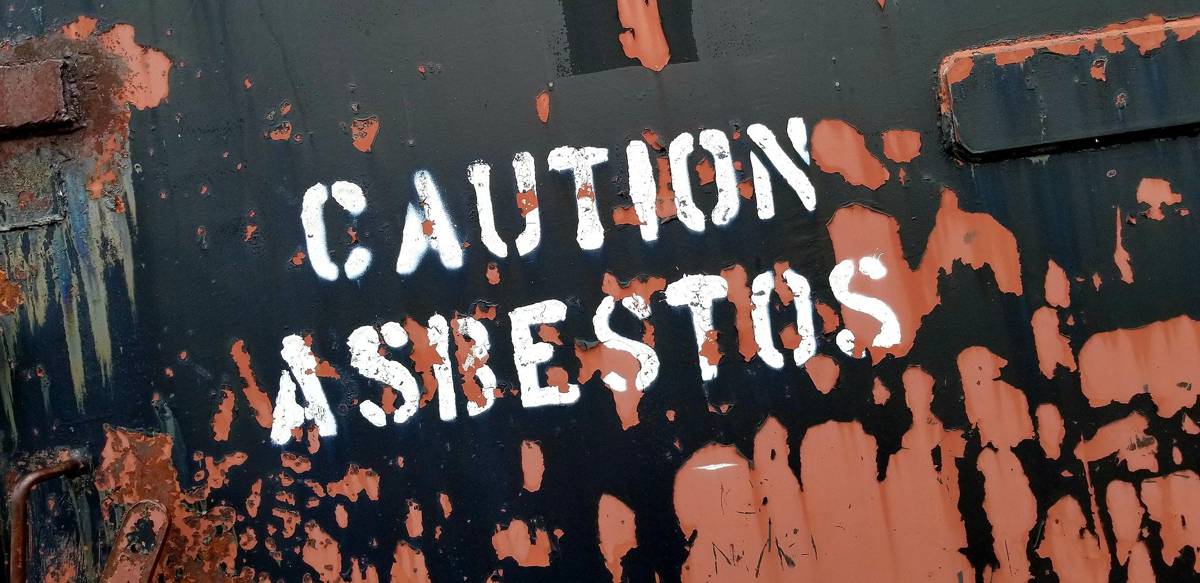

Caution is advised when undertaking tasks that require drilling holes or breaking out/pulling cables when the surrounding material is suspected or known to contain asbestos, as such activities are highly likely to release the hazardous fibres into the surrounding environment. In the event of a known or suspected ACM being disturbed, rail workers are required to adhere to the following steps:

- Immediately cease activity and evacuate all employees working in the area

- Secure the area and restrict access using appropriate measures

- Report the suspected or known ACM to the site/line manager

- Await confirmation that no asbestos is present before resuming work. If confirmed, the ACM should be sealed and labelled or, where necessary, removed.

How can SOCOTEC support rail organisations with asbestos management?

SOCOTEC’s Asbestos team is well equipped to support the rail network with asbestos management and consultancy services, adopting a client-focussed approach to ensure that your organisation remains fully compliant with its ‘duty to manage’.