Mecalac commits to the rail sector with new MRail-Series range of machines

Mecalac, a global leader in the design, manufacture and distribution of compact equipment for urban construction sites, has further strengthened its position in the rail sector with the launch of its brand-new range – the MRail-Series.

Consisting of four new models: two rail-road excavators on tracks, the 106MRail and the 136MRail (from 10 to 13 tons), and two on wheels, the 156MRail and the 216MRail (from 15 to 21 tons).

Mecalac MRail-Series: the strength of experience

Following the 714MW RR, the long-lasting success of the 8MCR RR and the exceptional start of the 216MRail last year, Mecalac is now offering a brand-new range of rail-road excavators, the MRail-Series. The manufacturer has been working with renowned rail partners for more than 20 years, developing comprehensive knowledge and insight in the meantime.

Mecalac is strongly positioned in the global market and has unveiled a new division specifically focused on the rail industry, from research and development to product and sales support. The new division harnesses Mecalac’s assembly line processes and quality standards, as well as its global dealer network.

The MRail-Series machines are assembled on Mecalac’s production lines. This gives the manufacturer the means to meet the specific needs of this market, while benefiting from a solid industrial organisation and guaranteeing product reliability.

Four MRail machines: a solution for every jobsite

The rail market is vast and comprises national railways, private tracks, tramways and underground networks. Track gauges and regulations vary from country to country. Jobsite requirements are also very different, depending on whether they are focused on maintenance, modernisation or the construction of new tracks. Taking these parameters into account, Mecalac’s MRail-Series offers the perfect machine for your needs.

The 106MRail and 136MRail tracked excavators build on the Mecalac MCR concept. This concept, the fusion of a compact loader and an excavator, blends the speed and productivity of a loader with the 360° rotation of an excavator. They are designed to be the ultimate utility machine for the majority of service and maintenance works. They are also ideal for works in tunnels or in tight areas.

The 106MRail is the smallest machine of the MRail-Series. It features a two-piece boom with offset as standard and is extremely compact. Easy to operate, it is also the ideal support unit for larger machines.

The 136MRail provides even higher performance to increase overall productivity on national rail networks. It is equipped with numerous safety features and can be fitted with a pneumatic system for rail trailers and rail car brakes.

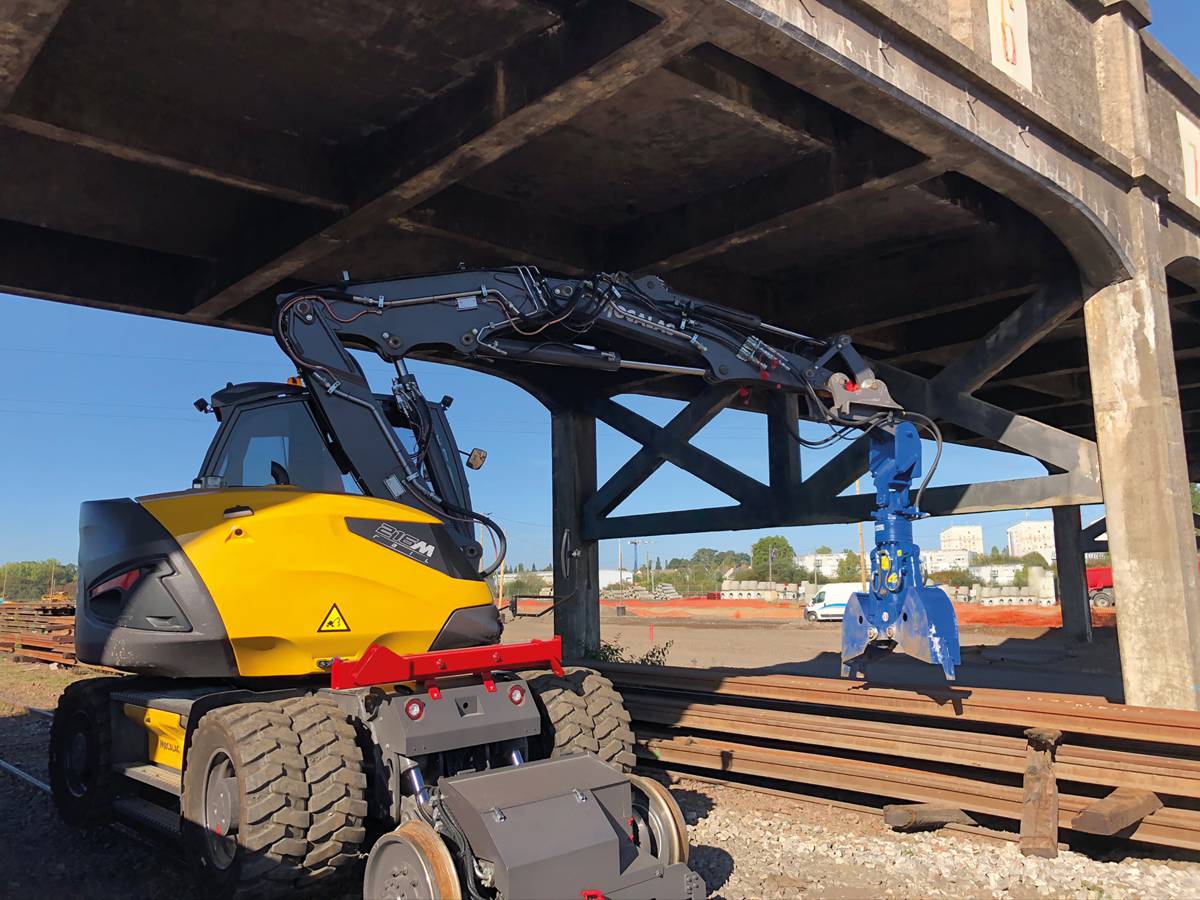

The 156MRail and 216MRail wheeled excavators are based on the Mecalac MWR concept. They provide solutions for all types of tracks and a high degree of freedom of movement, especially when moving the boom under height constraints (like catenaries).

The 156MRail is perfect for urban networks, subways and private tracks. It is a medium-sized machine that meets the requirements of rail applications without the costly and complex systems linked to regulations. It is the easiest and most profitable solution for working on rails.

The 216MRail is the strongest machine in the range and has been designed for the toughest jobs– with zero compromise on manoeuvrability, agility and compactness. It is compatible with the EN15746 regulation, the most stringent regulation for the rail sector. What’s more, it has a wide range of safety features and a pneumatic system for trailers.

Working on rails has never been easier with Mecalac

This new range of rail-road excavators combines high performance and agility to let you work with unrivalled freedom of movement in the highly constrained areas of the rail industry.

True compactness is not just a matter of rear radius. Not obstructing the adjacent track and working in areas where very little space is available – at the rear, at the front and in height – is true compactness.

Superior balance is a key benefit of the Mecalac MRail-Series. The patented design of our booms gives the machine an outstanding weight distribution for balance and force. Add in Mecalac’s unique architecture and you achieve best-in-class stability for exceptional lifting performances.

Full 360° direct visibility is a major safety benefit for both the operator and those on site. Mecalac also offers unique solutions – maintenance from the ground level, including for refuelling, easy access to the cab and unbeatable visibility. This helps you tackle even the most complex tasks with peace of mind.

Compactness, stability, safety, agility, performance and versatility – Mecalac’s MRail-Series rail-road excavators offer the best solution on the market.

The rail industry is booming worldwide. Rail-road excavators are the best tools not only for the maintenance of existing networks, but also for the construction of new tracks. Mecalac is committed to providing solutions that will revolutionise rail-road excavators and change the lives of users.

The manufacturer will officially launch these new models at the IAF international trade fair, one of the key events in this segment, which will be held in Münster, Germany, from 31 May to 2 June 2022.