Mapping the Smart Factory future with AI Automatic Error Detection and Diagnostics

In predictive maintenance, the most critical factor that safeguards against machine downtime is early detection and remediation. Futuremain from Korea is the only predictive solution provider in the country that can deliver a solution with an accuracy of 90.3%.

Its flagship products ExRBM and AR integrated ExRBM AR+, have received excellent awards from the national science institute, a government research organization for proven performance. Both products have recently gained strong interest from Smart Factories around the world as well.

Traditionally, error detection is only possible through a real-time Condition Monitoring System or Vibration Monitoring System, typically used in heavy machinery applications. When abnormalities occur, both systems require the manual work of experts to analyse a large volume of data to determine the root cause. Often, these data experts are not immediately accessible, and the machines must shut down to complete the analysis. It is an expensive proposition and difficult to engulf. In response, Futuremain has developed an automatic error detection software that uses big data and innovative AI technology to manage and improve predictability.

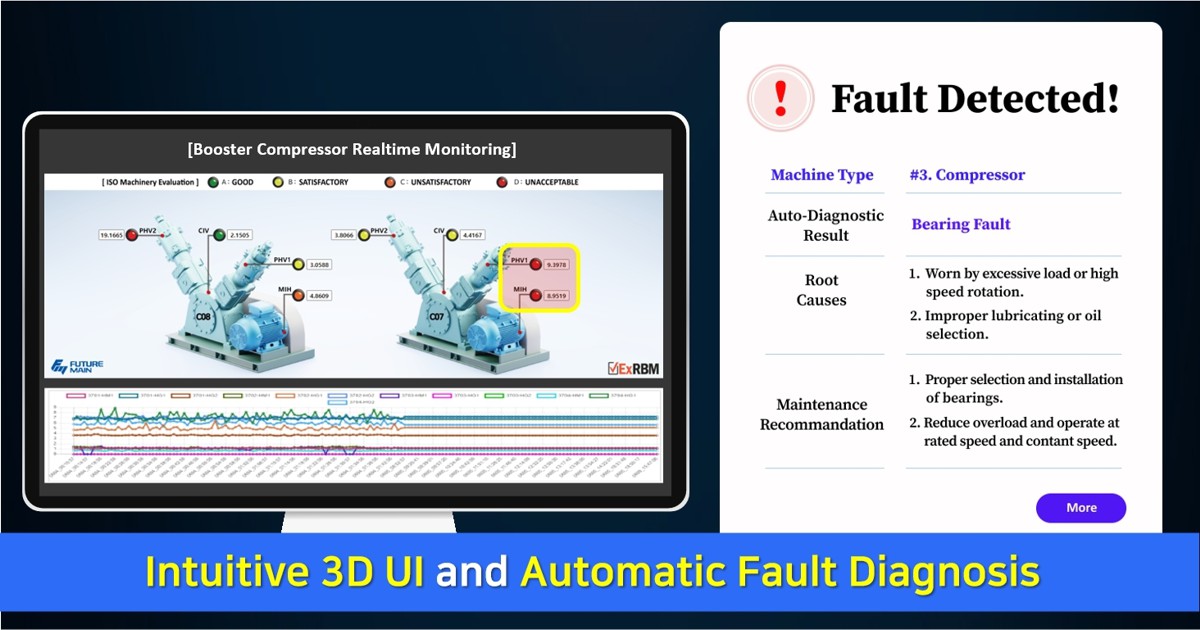

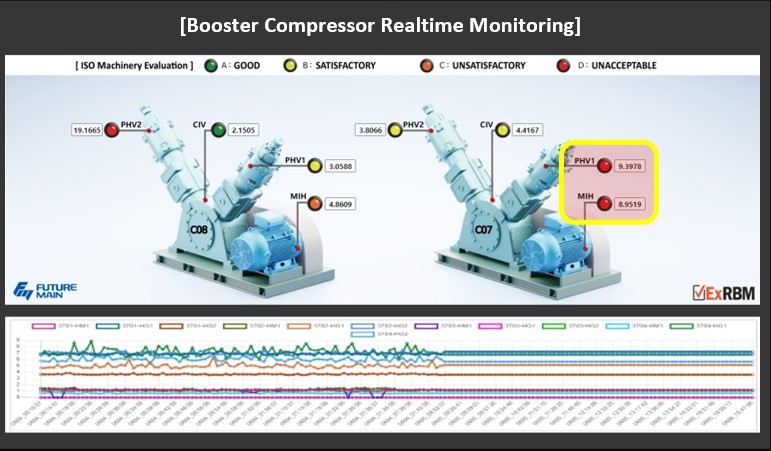

ExRBM collects machine data from vibration, temperature, current, and pressure changes in real-time. It then informs the operator on the status of the condition and risk level, besides automatically conducting diagnostics on any other error against a pre-set parameter.

ExRBM analyses the cause of the problem and further provides repair recommendations, allowing an operator to remedy problems faster. That makes the product a true winner in preventing major financial disasters ahead of time before machine failure strikes.

Application-wise, features of ExRBM are ideal for the chemical, gas, petroleum, energy, robotics, and manufacturing industries, particularly in a large manufacturing environment for monitoring heavy machinery having similar to rotating or reciprocating mechanisms.

ExRBM provides high compatibility and expandability with other comparable solutions. It can also integrate with Management Execution System and Computerized Maintenance Management System, which makes ExRBM versatile.

Combining proprietary technologies in predictive maintenance and augmented reality, the company has developed an application called Smart AR Machine Maintenance running on a mobile platform.

A mobile viewer that allows users to examine the condition of a machine. Additional features include access to machine drawings and maintenance video guides.