A guide to Aluminum Profiles and types

The process of forcing aluminum alloy material from a specific cross-sectional profile is known as Aluminium extrusion.

The process puts the physical characteristics of Aluminium to use in a very unique way. The flexibility, also known as malleability, helps it to be easily processed. Because aluminum has one-third stiffness of steel, the resulting product offers strength and stability.

The process of Aluminium Extrusion

The aluminum extrusion process is also known as the bulk plastic deformation process. To begin the extrusion, the billet of aluminum is heated according to a specified temperature that is below the material’s melting point, to facilitate the flow of the material. In the second step, the heated billet is forced through a die that is shaped to form a billet in a cross-sectional area.

Advantages

Aluminum extrusion is relatively more beneficial than other processes and materials.

Light-weight

First, because Aluminium extrusions are lightweight, the weight of aluminum is one-third of steel and iron, making aluminum easy to handle and ship making it an attractive purchase where less weight and cheap transportation is a priority.

Strength

Aluminum extrusions can be made as strong as desired for applications; the strength can be concentrated where it is required by varying thickness of the wall and internal reinforcement of the tooling die.

Strength and weight combination

As mentioned earlier aluminum extrusions are lightweight but high in strength, his unique combination makes them ideal for applications where load carrying is a key performance.

Flexible

Aluminum extrusions can handle the load, they can flex under the load and can even spring back from a shock impact, and this ability is the reason why aluminum is used in automotive crash management systems.

Corrosion-resistant

Aluminum does not rust because it is naturally covered from its oxide film, a protection that is enhanced by anodizing and other filming methods.

Thermal conductors

Aluminum is twice as conductive as copper, making it an excellent alternative for electrical connectors.

Sustainable

Aluminum is a sustainable metal, even after recycling it will not lose its properties, and it is key fact that aluminum is often time recycled and the functionality and the aesthetics remain intact.

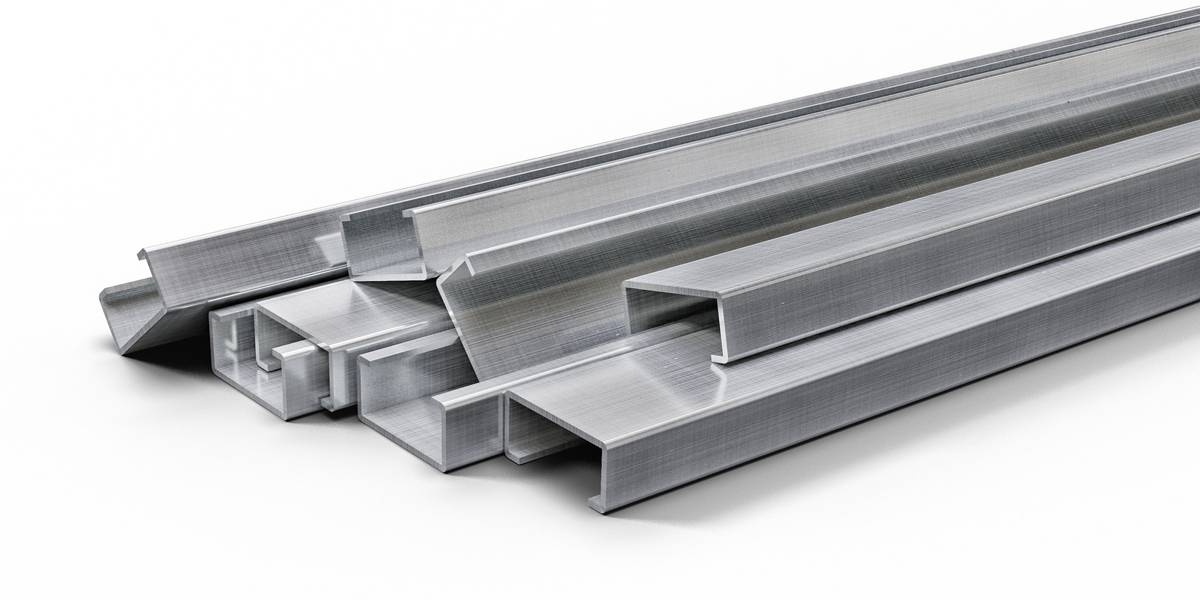

Types of Profiles

Aluminum extrusion profiles come in a variety of options depending entirely on the applications. Profiles or in other words cross sections come in a variety of thickness options, which is very important in providing form or function to a particular structure. Manufactures greatly enjoy working with aluminum in profile production because of the physical properties aluminum offers. Aluminum, as mentioned earlier, is light-weight, malleable, versatile, and a great thermal conductor and most importantly it is cost-friendly.

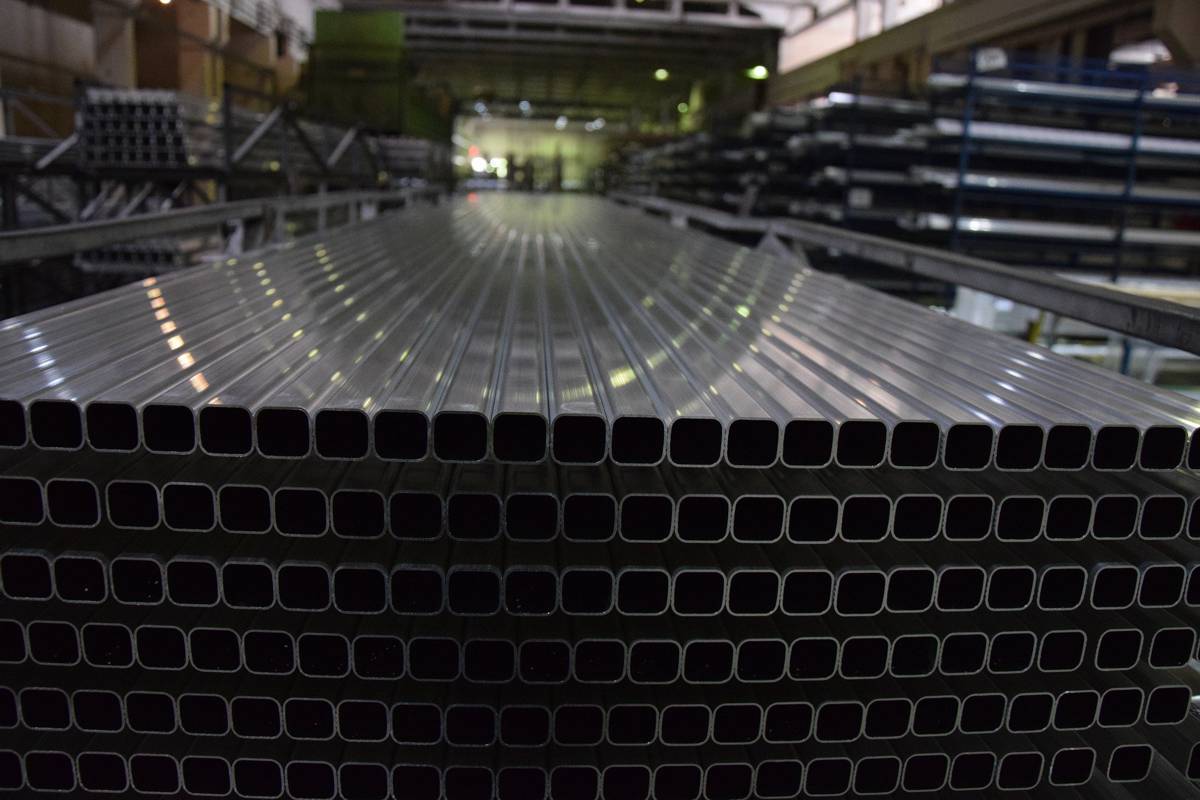

Hollow beam

As the name suggests, hollow beam aluminum profiles mean hollow beams of aluminum with no cross-sections. These are used in modular installations specifically in constructional designs. Hollow beams exist in a variety of shapes with specific sub-classification for each. These come in form of rectangular, square-shaped, triangular beams. Hollow beams are used as a support framework for buildings, bridges, etc.

Square Profiles

These profiles can be classified as a subsection of hollow beam aluminum. They have a similar use as the hollow beams; the only difference is that square beams can provide more sustainable and stable support. Square profiles can be seen as a part of wall load bearings as well as for the support of pillars. Square profiles are made seamlessly and non-seamlessly depending on the process of manufacturing. The process of making square profiles involves a continued flattening of an aluminum sheet and then joining the corners in such a way to form a square. To smoothen out the insides of the profile, a high-pressure piercing point is passed through it.

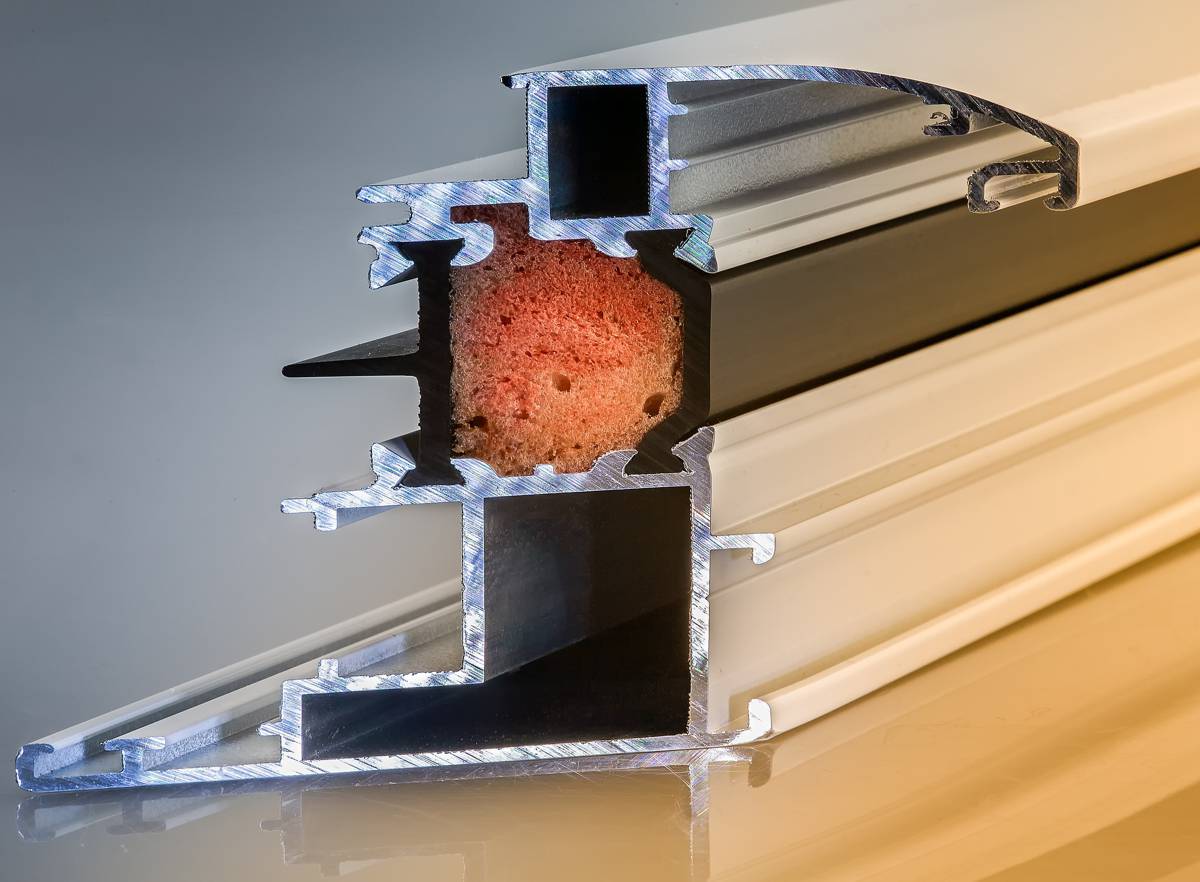

SD Aluminium profiles

Aluminum profiles are found useful in both large-scale and small-scale applications. Extruded aluminum profiles are widely used as a part of the window’s framing. Apart from being flexible and, lightweight aluminum is also corrosion resistant which is why it is an attractive option for window framing.

The best choice for sliding window frames is the SD aluminum profile. Windows are exposed to harsh environments such as rain, storm, sun, humidity, dust, and so on, which is why they need to be made from a good material that can ensure sustainability. The sliding functionality and resistive features of SD aluminum profiles make it a better option for window framing.

RCW Profiles

RCW profiles are used in high buildings and are usually applied to curtain walls and mullions. RCW profiles do not offer any function related to the structure, their primary function is to act as a barrier to prevent the entry of environmental elements such as dust and rain into the building.

Curtain walls are often Aluminium framed, and they are avail be in a variety of sizes. These profiles deal with preventing any unwanted substance from entering the premises of the building, which is extremely important. RCW profiles are fitted with other materials as well to prevent occurring of leakages.

Door section

Door sections are also named ED sections; they are used in heavy-duty glass doors for buildings. They work as a part of the mechanism of push doors and often time entire system depends on them.

You will find glass doors without a mechanism in different types of commercial spaces. The classic design offers both functionality and form. Aluminum door sections are extremely useful in securing the glass and preventing it from falling apart or suddenly toppling over.

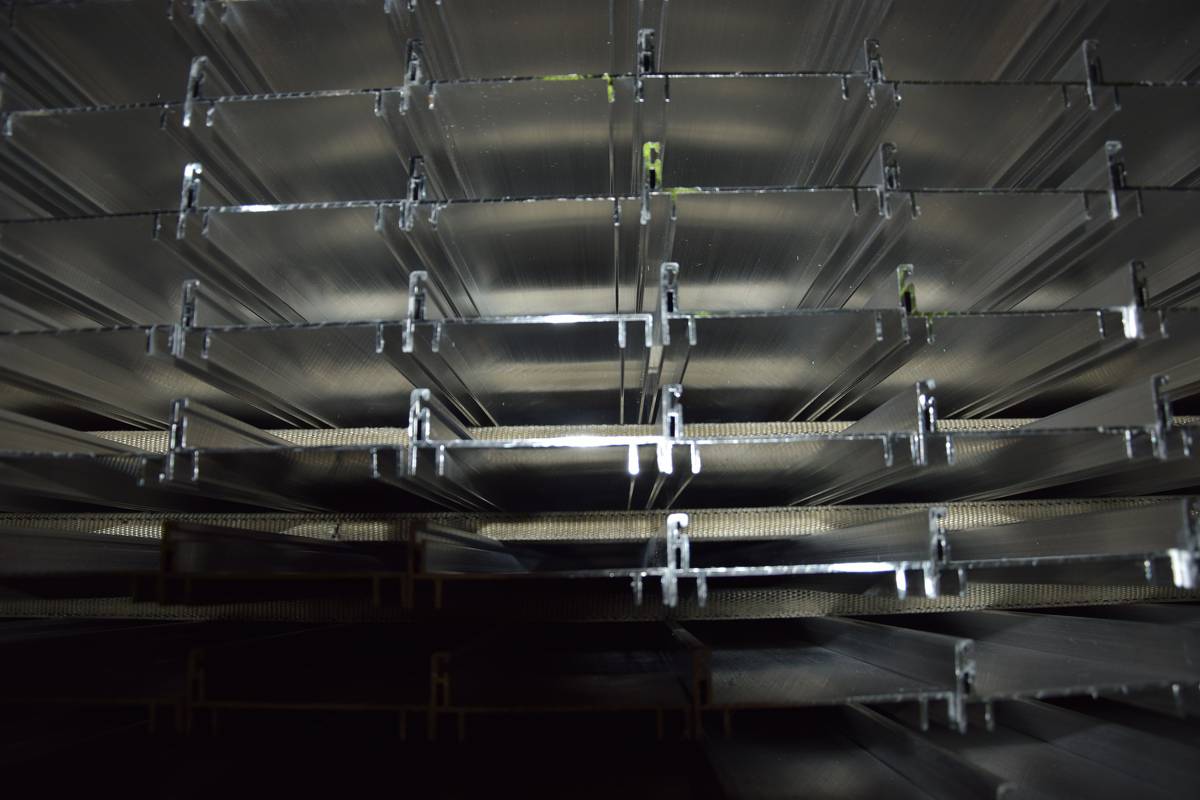

Louver Profile

A louver demonstrates a set of angled slats, a regular interval on a door, shutter, and screen to allow the light to pass through it. Louvers are used as a passage for natural lighting and ventilation. They are also helpful in keeping the debris from entering inside the building premises. Aluminum louvers can be customized in different designs depending on the building structure. The aluminum material can let cool the natural ventilation inside and is also able to keep water from coming inside.

T Section

The T-shaped sections are simply T-shaped aluminum extruded product that provides support in different directions. T section products contain components such as the horizontal flanges, vertical webs.

The structure of this type of profile makes it useful to be used in a corner and as part of a truss network. It can easily be fitted with other types of aluminum profiles such as square and hollow beam profiles. For enhancing sustainability, fittings are also attached to the T section to increase the support level.

Conclusion

Different types of profiles are engineered in a way to provide sustainability, form, function, and support. Aluminum profile extrusion manufactures have been to include different types of customizations on these profiles to match with the applications such as sliding doors, heavy-duty doors, and window framing.

Aluminum profile extrusion was initially used to provide structural support to the buildings, but it is also proved useful to be used as protection from external elements.