Scope secures funding for automated rope inspection for the utility industry

Scope Computer Vision Technologies, an inspection automation company that builds deep learning vision systems, today announced it has raised substantial funding from private investors across the state of Texas. The investment will help drive product development and market education around automated inspection in the utility industry.

“This investment fuels our ongoing commitment to revolutionizing the way people inspect critical product applications in zero-fail situations,” CEO Justin McCoy said. “In circumstances where people’s lives rely on a product’s ability to perform, we must be able to accurately assess that product’s health every time it is used.”

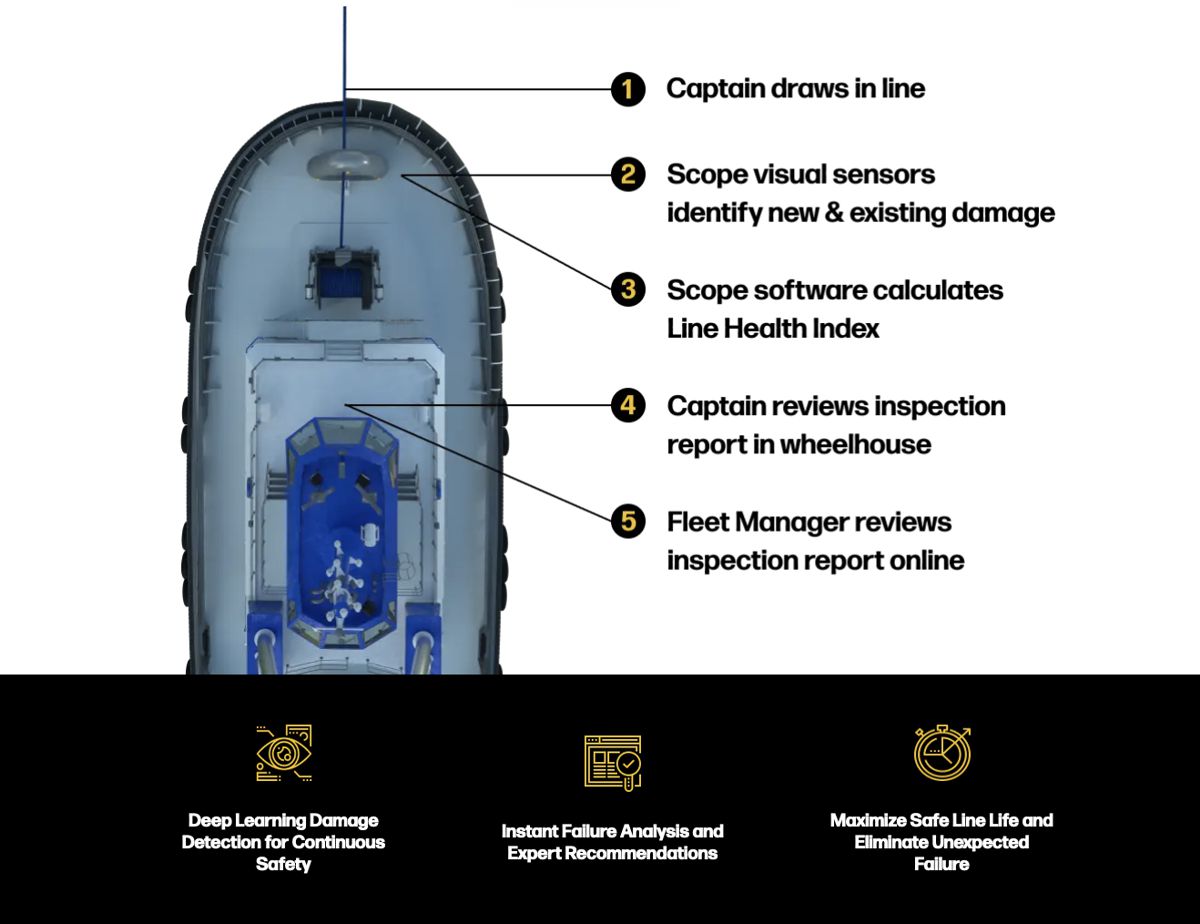

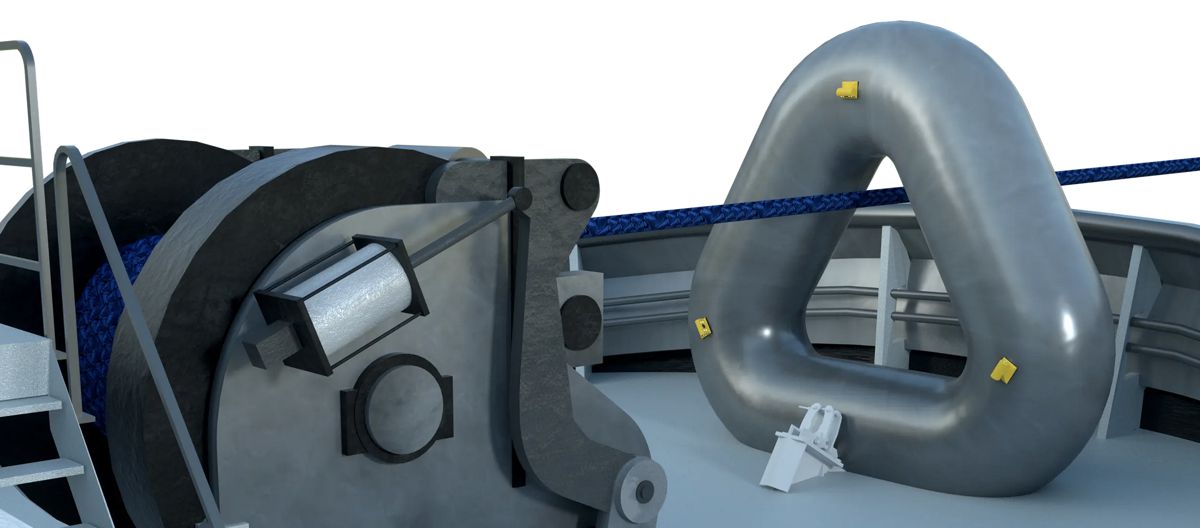

Launched in the summer of 2019, Scope is developing automated inspection technology that assesses high performance synthetic rope for manufacturers and operators of utility stringing equipment and users in the maritime industry such as tugboats and mooring systems. This is the first outside investment that the company has taken on.

“Prior to Scope, standard best practice was to inspect miles of synthetic rope by hand, visually looking for damaged areas and making a judgement call on whether the line was safe to use,” explains COO Mike Poroo. “Our technology automates this labour intensive task in real-time, in line with operations, with higher accuracy.”

Scope’s first product, Scope Control, is due to release in the Spring of 2022. The product will be a standalone unit that is positioned between pullers to inspect long distances of stringing lines.

“With this product we aim to prove that the technology can be relied on as a form of measurement for the quality of a line,” Justin McCoy continued. “The industry is in dire need of a tool to standardize inspection practices.”

The Scope Control device uses the latest in sensor and camera technology paired with deep learning neural networks in order to recognize and grade the severity of damage modes that it detects on a stringing line. This is a significant shift from manual visual inspection where an operator is expected to accurately inspect miles of rope at a time. With manual visual inspection, results can vary as much as 45% from person to person, whereas the Scope Control technology is as consistent as only automation can be. Operators can continuously monitor line health in real time with high precision.

The product’s neural networks were trained to a very high level of accuracy through another Scope product, Scope Capture, which Scope developed for manufacturers of rope. Scope Capture enables manufacturers to build accurate recognition models that are specific to their own rope products.

Scope founders believe that users of rope will demand highly accurate models from manufacturers of rope products, and Scope can serve both ends of the technology spectrum.

Mike, concluded: “We can equip both the manufacturer and the user of rope products in a way that establishes a common reference for the quality of a rope that is consistent across the industry, resulting in compliance that is realizable and maintainable.”