5 technologies improving productivity in construction

It’s never unusual for a construction project to run over budget or behind schedule. As a result, contractors can always benefit from new technology that helps improve site productivity and reduce costs.

Novel robotics, software and even innovations like augmented reality are helping contractors identify and manage site inefficiencies that can slow a project down or make work more expensive.

These are five of the most important technologies for the industry right now — and how they’re likely to change construction in the near future.

1. Building Information Modeling (BIM)

Contractors need tools that help them keep track of all the elements of a project at the same time as construction projects become more complex.

Building information modeling (BIM) systems provide a centralized information hub that all stakeholders in a project can use to understand a construction job, its workflows, current progress and potential issues.

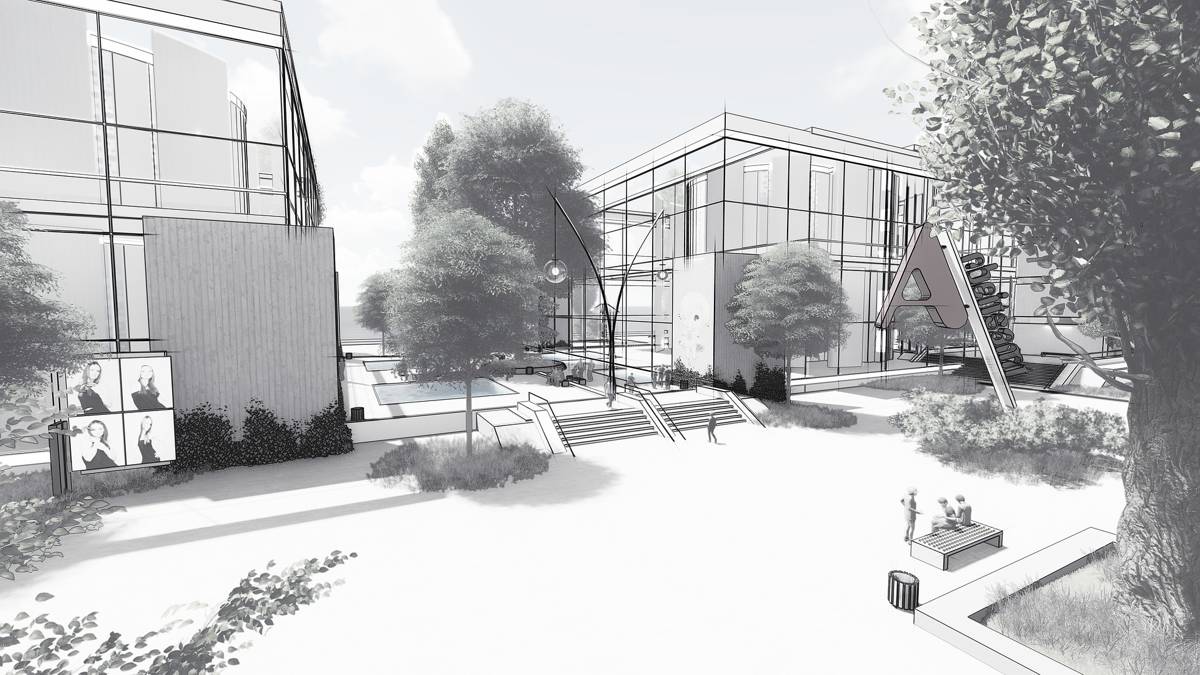

BIM relies on intelligent models, 3D replicas of a building generated from documentation and on-site information sources. Tools like 3D scanners, IoT sensors and robotic surveying solutions allow contractors to continuously gather information on the job site and upload it to a cloud-based BIM model, where stakeholders can access it.

The model ensures gathered information is accessible and centralized, making it easier for off-site stakeholders to follow the progress of a job or review important documentation.

A BIM system allows contractors to provide more effective updates than those that rely on handwritten notes or photos of a construction site, which can be inaccessible and incomplete representations of progress.

IoT sensors and 3D scanners make it possible to offer more frequent progress updates — helping stakeholders better understand how the project is coming together.

In practice, BIM can help reduce communication errors, improve stakeholder engagement and prevent revisions. As a result, using BIM may avoid budget and schedule overages.

2. Virtual Design and Construction (VDC)

BIM is often a key component of an emerging construction management system, virtual design and construction (VDC). This involves the use of performance and digital models to streamline construction work.

Companies that adopt VDC may also use three-dimensional computer-aided design (3D CAD) or even more advanced technologies, like digital twins.

These tools help contractors and designers carefully plan a project ahead of time. Because software like BIM and 3D CAD allows for the visualization and simulation of a design, they can help construction companies identify potential issues before construction begins.

Preventing these issues can help reduce the risk of revisions and rework, lowering a job’s overall cost.

3. Digital Twin Technology

In some cases, contractors may want to simulate building function and construction with extremely high levels of detail. They may also want a model building owners can use to manage the structure after handover. BIM models are not always intended for this kind of long-term use. Instead, contractors may leverage digital twins.

A digital twin is a virtual representation of a real-world object, place, component or process. What makes a digital twin different from a 3D model or blueprint is fidelity. They replicate their source with extreme attention to detail, modeling subcomponents, simulating materials and recreating systems. In theory, they’re close to a one-to-one virtual copy of the object they represent.

These twins allow for the simulation of construction processes and workflows, as well as building systems.

For example, a contractor working on the design and construction of a new hospital may need to pay close attention to cooling and airflow. A digital twin makes it possible to effectively simulate ventilation, HVAC system performance and building temperatures, allowing the contractor to predict real-world airflow during the design process.

Digital twins are being used in construction more often to plan projects, simulate potential designs and prep completed buildings for handover. A twin may also be used long after construction is complete to streamline building management and simplify renovations.

The same simulations contractors may use to simulate a design can help owners pinpoint shortcomings in building function — allowing them to make more cost-effective upgrades.

4. The Internet of Things

The construction site can be difficult to monitor. The current location of assets, raw materials, workers and heavy machinery is all important information, but managers may not be able to keep track of these resources on their own.

IoT sensors and tracking devices can help construction companies monitor essential assets — ensuring employees know where they are and preventing the loss or theft of important goods.

Simple IoT tags that use GPS or RFID technology can continuously upload information on an object or machine’s location to the cloud. Managers can access this information from anywhere, allowing them to track individual items or see how goods are moving around the construction site.

In practice, this can allow managers to keep tabs on important goods and visualize the flow of resources around the construction site — potentially helping them spot layout bottlenecks, safety risks and inefficiencies.

Many construction companies are also beginning to use IoT devices for safety purposes. Smart wearables — including boots, vests and visors — can provide safety data in addition to the tracking information other IoT devices offer.

For example, a smart boot may include acceleration sensors that can detect when a worker slips or falls. The system can immediately call for help, ensuring the fastest possible response. It also tracks the worker’s location, so managers and other employees know exactly where they are.

Construction is one of the most dangerous fields for American workers, and construction employees face risks like falls, struck-by incidents and heavy machinery every day. Devices like these could help make things much safer.

5. Artificial Intelligence and Machine Learning

Forecasting is often one of the biggest challenges for contractors. Good predictions help prevent budget overages, but there are several factors contractors need to consider. The complexity of a construction project may make forecasting with a conventional approach almost impossible.

The growing accessibility of artificial intelligence (AI) has led to the growth of construction AI solutions that can help contractors predict project costs, identify risks and make better decisions.

AI is particularly good at finding patterns in vast amounts of data, making it an effective tool for generating forecasting algorithms. AI-powered predictive algorithms can utilize various data from the construction site — including information from BIM models and IoT devices — in predicting costs or estimating site risks.

Information from past projects can help improve an AI algorithm. After a project is over, businesses can feed information back into the algorithm, improving the accuracy of its predictions. As a result, companies that adopt predictive technology may find the forecasts improving over time.

While still experimental, AI algorithms are a powerful tool for construction companies wanting to identify potential risks that human analysts may not uncover on their own.

These New Technologies Can Help Make Construction Faster and More Cost-Effective

Contractors and construction companies wanting to reduce inefficiencies and keep projects on schedule are using new technology — like BIM, digital twins, AI and IoT devices. These tools can help companies track projects more effectively, forecast construction costs and identify potential oversights.

Many of these technologies are still experimental, but they’re becoming increasingly common in construction. They may become standard in the industry over the next few years, completely transforming how new structures are built.