Hitachi adds largest Zaxis-7 Wheeled Excavator to the range

The new Hitachi ZX220W-7 wheeled excavator holds strong appeal for both owners and operators, with an extensive range of features designed to help control their profitability, comfort, safety and uptime.

This highly versatile model, the largest in the Hitachi wheeled excavator range, also benefits from unrivalled levels of support over its life cycle.

Improve your profit

Owners’ profits will increase thanks to the impressive fuel economy of this Stage V-compliant machine. Its unique and industry-leading HIOS III hydraulic system achieves higher levels of productivity with better fuel consumption than previous models, helping to reduce running costs. Operators can also control the fuel efficiency and costs with the all-new ECO gauge, which is clearly visible on the large LCD monitor.

Owners can further boost their profits by working on a wider variety of projects thanks to the excellent versatility of the Zaxis-7 wheeled excavator. It can be used with a broad range of Hitachi attachments, such as tilt rotators and buckets, breakers and sorting grabs, to suit the application. These are easily changed using the enhanced attachment support system and can be conveniently transported using the optional trailer support package.

The new model can also be fine-tuned to suit the operator’s preference and job site requirements – for optimum productivity, while reducing fuel consumption.

Feel the difference

The redesigned Zaxis-7 cab is the perfect working environment for operators. Ultra-spacious, it offers the ultimate in comfort and quality, with low noise levels and less vibration than the previous generation.

Operators will feel less tired at the end of their shift thanks to the synchronised motion of the seat and console. Easy operation also comes from: the new ergonomic design of the console and switches; convenient access to the controls; and features such as cruise control, automatic transmission and the optional ride control system that suppresses vibrations from the front attachment.

Added functionality to the easy-to-view screen and joysticks, and the auto working brake, have also been incorporated to this state-of-the-art cab to ensure an effortless working day.

Increased safety

The cab also offers a superior view of the job site to protect operators and the machine from potential hazards. Visibility is boosted by an exceptional 270-degree bird’s-eye view with the Aerial Angle camera system.

Operators can choose from six image options on the monitor to view the immediate environment. Their vision through the cab’s front window is also improved by the slim steering column (with wider adjustment angle) and smaller steering wheel.

To enable operators to work more confidently and productively, even in challenging conditions, the Zaxis-7 wheeled excavators are fitted with new features such as LED work lights, a windscreen wiper with an increased sweeping area, and larger mirrors. Heated mirrors are also available as an option. For additional safety, the upper structure and front attachment will lock in place when the machine is in the correct position, for driving on public roads.

Boost uptime

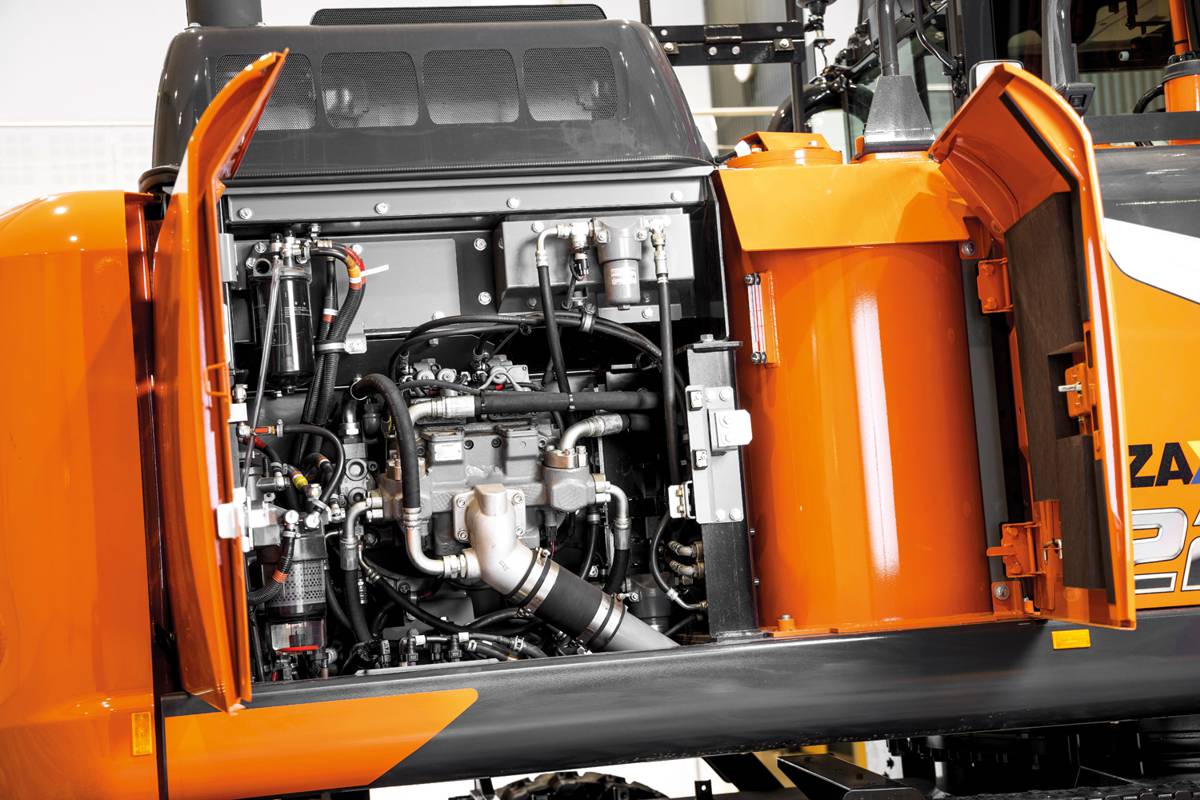

Like all new Zaxis-7 wheeled excavators, the ZX220W-7 has been built to last. Rigorous testing at dedicated facilities in Japan ensures it will deliver a reliable performance and high levels of uptime.

Durability and quality are found in every detail, such as: the single-piece undercarriage that benefits from greater oscillation; enhanced outrigger hydraulics; and fenders protecting the upper structure from dirt.

For greater lifting capacity and exceptional stability, customers can choose from a range of counterweights, and between standard 2,550mm or wide 2,750mm axles for the ZX220W-7. Downtime is prevented by the durable after-treatment system, and minimised by the priority given to easy maintenance and cleaning.

Fleet management

Hitachi remote monitoring systems enable owners to feel in total control of their fleet and workload with access to vital data courtesy of Owner’s Site and ConSite. Both systems send operational data via GPRS or satellite from the excavator to Global e-Service on a daily basis. ConSite summarises the information in a monthly email, and the ConSite Pocket app shows real-time alerts for any potential issues.

Machine software updates can be carried out remotely by dealers for added convenience using ConSite Air. This feature also enables Zaxis-7 excavators to be monitored with Hitachi’s diagnostic tool (MPDr. Remote Access) from anywhere in the world, ensuring maximum uptime.

In addition, a unique innovation continuously monitors the quality of engine and hydraulic oil, 24/7. Data is transmitted daily via two oil sensors to Global e-Service. These detect if the oil quality has deteriorated, due to contamination or low viscosity. It reduces maintenance and unscheduled downtime, and gives owners peace of mind thanks to scheduled servicing and a higher resale value.

Create your vision

“We’re delighted to introduce the largest Zaxis-7 wheeled excavator model,” says Hitachi Construction Machinery (Europe) NV Excavator Product Manager Wilbert Blom. “We’ve had a hugely positive response from customers to the new range so far, and we hope the ZX220W-7 will be equally well received.

“It offers outstanding versatility for a wide range of applications when used with Hitachi attachments, and delivers an exceptional performance – allowing our customers to create their vision.”