Driving forward decarbonisation with Shell

Construction plays a vital role in enabling social and economic progress, but it must accelerate action on decarbonisation to meet the Paris Agreement objectives through participation in the just transition.

We spoke to Raman Ojha, Vice President of Shell Construction and Road, about how the industry can reduce emissions immediately in its journey to net-zero emissions.

As the Vice President of Shell’s new business unit for construction, what are your ambitions for the sector as you come into your new role?

“Construction has, and always will be an integral sector of the world’s economy. As a sector that employs hundreds of millions of people and accounts for 13% of the world’s GDP, it will also be critical to the world’s recovery post COVID. However, it’s also one of the fastest growing sources of emissions and is facing increasing pressure to decarbonise from governments as well as society. This is where we need to focus.

“We all know the sector has taken positive steps on decarbonisation thanks to lower-carbon products, more efficient technology, digitalisation, but there is still a lot to be done. Immediately and significantly reducing emissions from construction is key for reaching the goals of the Paris Agreement. I believe, at this critical moment, the industry is ready for making the choices that will lead it to net-zero.

“There are multiple challenges to decarbonising construction, and it will take collaboration across the entire value chain to overcome them. A combination of technology, low-carbon solutions, and supportive regulation can accelerate progress to net-zero. Shell has recently reorganised its business-to-business activities working sector by sector to address specific customer needs, helping our partners accelerate their decarbonisation journeys.

“Shell Construction and Road was created to support the decarbonisation of the construction industry across the value chain by leveraging our strong bitumen business, our expertise in low-carbon fuels and cleaner energy solutions. We do not have all the answers and we know we will have to learn from others if we are going to be successful, but I am leading a fantastic team which is committed to working with our partners to help them reduce their own emissions.”

Net-zero construction will require multiple levers. How are Shell working with its partners to develop these?

“Each segment of the construction value chain will need to invest in different decarbonisation solutions.

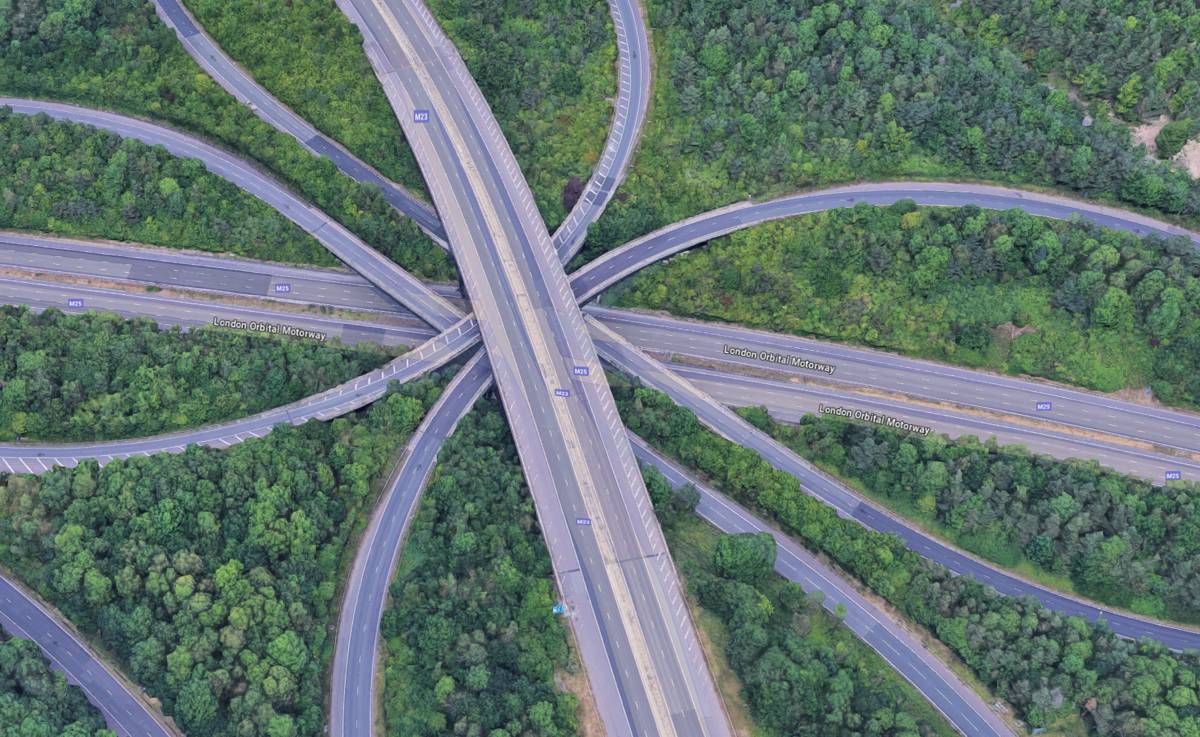

“Low carbon fuels, including biofuels and hydrogen, and electrification have the potential to significantly reduce emissions across the construction value chain, with particular focus on raw material transportation and plant operations. There is also a very clear application for them in heavy-duty transport fleets servicing construction sites and on-site machinery.

“Regarding the decarbonisation of raw materials, their carbon impact can be reduced with lower-carbon alternatives; we have recently developed an innovative binder solution using an additive chemically converted from plastic waste and blended into bitumen that retains the lower production and laying temperatures of low-temperature technology; we have also developed a new bio-component binder that locks carbon into asphalt and bitumen, turning the road into a technical carbon sink.

“There are multiple solutions available to reduce plant operation emissions, such as using binders that require less heating, like low-temperature bitumen or energy solutions with a lower environmental impact.

“At the final stage of the value chain, operational efficiencies across construction sites and transport routes can be unlocked using digital solution like telematics. We are working with our partners today to see how each of these solutions can be used and adapted to fit the customer’s specific requirements and objectives.”

How important is value-chain collaboration for decarbonising the industry?

“I whole-heartedly believe decarbonising construction is only possible with widespread collaboration across the entire sector ecosystem; coalitions of businesses, consumer, and industry associations need to form to make real change. Although construction is a complex, fragmented sector, all parties involved can offer valuable insights, technical expertise and capabilities that can help the industry reach net-zero.

“Shell is here to play its part, as an energy supplier, energy user and a partner for change. Together with my team we will work with our customers to continue to invest in research and development, develop new and lower-carbon solutions and be a catalyst for decarbonisation across the ecosystem.

“While currently I see decarbonisation being driven more by voluntary demand from within the industry, there is undoubtedly an important role for supportive policy frameworks. As the largest global industry, policies should be consistent across different regions to ensure a level-playing field in reporting emissions. I understand this is a process that takes time, but supportive regulation needs to be developed much more quickly to help guide and encourage the industry toward a net-zero emissions ambition by 2050.”

Aggregate Industries recently announced a partnership with Shell to produce the UK’s first-ever commercially available biogenic asphalt. How will this product help reduce emissions from road building?

“I was really pleased to see the UK market take on this innovative collaboration with Aggregate Industries. Biogenic asphalt has immense potential for the industry, effectively turning the road into a technical carbon sink with no effect on performance. It locks carbon within the asphalt rather than releasing it back into the atmosphere.

“This solution is a great example of how innovation can help decarbonise and improve the circularity of construction at the same time. It incorporates our Shell Bitumen CarbonSink, a new bio-component binder, which enables the biogenic components to remain locked in the road surface, even when it is recycled at the end of its life.

“We know our customers face challenges in making sustainability investments and testing new products. Our partnership with Aggregate Industries stands as an example of how the industry can come together to reduce emissions.”

You spoke about how biogenic asphalt traps carbon emissions within the circular economy. How important is it to increase circularity across construction?

“Shell’s ambition and Shell Construction and Road’s ambition, is to use resources and materials efficiently through reusing and recycling them.

“I believe lowering demand for resources through design and process optimisation and increasing closed-loop circularity for materials must play a key role in decarbonising construction to ultimately reduce use of new resources in a way that does not compromise end-quality. Circular principles should be embedded in the design of infrastructure projects to help minimise waste in communities.”