XCMG launches Hoisting Equipment Operation Management Platform

XCMG, a world leading construction equipment manufacturer has presented the latest technology advancements for smart hoisting solutions.

XCMG released a hoisting equipment operation management platform, that aims to solve pain points which have plagued the industry for years, such as difficulties in supervising equipment operation, project situations, and safety operations.

This digital solution is the first of its kind to be used in the industry in order to ensure the safety of each construction project.

After several years of intensive research and development of smart construction site solutions, XCMG, the manufacturer of one-third of the world’s crane equipment, developed this platform. The Platform focuses on cluster construction scenarios such as in the petrochemical industry, urban construction, and bridge construction.

Furthermore, it utilizes advanced technologies such as big data, cloud computing, artificial intelligence (AI), Building Information Modelling (BIM), and Internet of Things (IoT) to formulate a holistic and effective operation management platform.

“The Platform supports the operators and project management teams to work on the construction sites remotely with visualized data and information on multi-model, cross-brand, and different-year machines, learning the real-time situation of construction progress and equipment status,” says Li Zhongfu, head of XCMG Machinery’s information management division.

The introduction of the Platform is another step toward making ‘cloud supervision’ an industry norm.

With the Platform’s remote control centre, an overview and detailed data of the entire construction project is shown on a large monitor, including their location, switch-on status, and detailed operations data, which can be accessed in real-time by video and other information format.

Additionally, efforts were made to improve equipment health management. The Platform provides regular maintenance reminders and fault warnings, which helped to reduce equipment failure rates by over 50%.

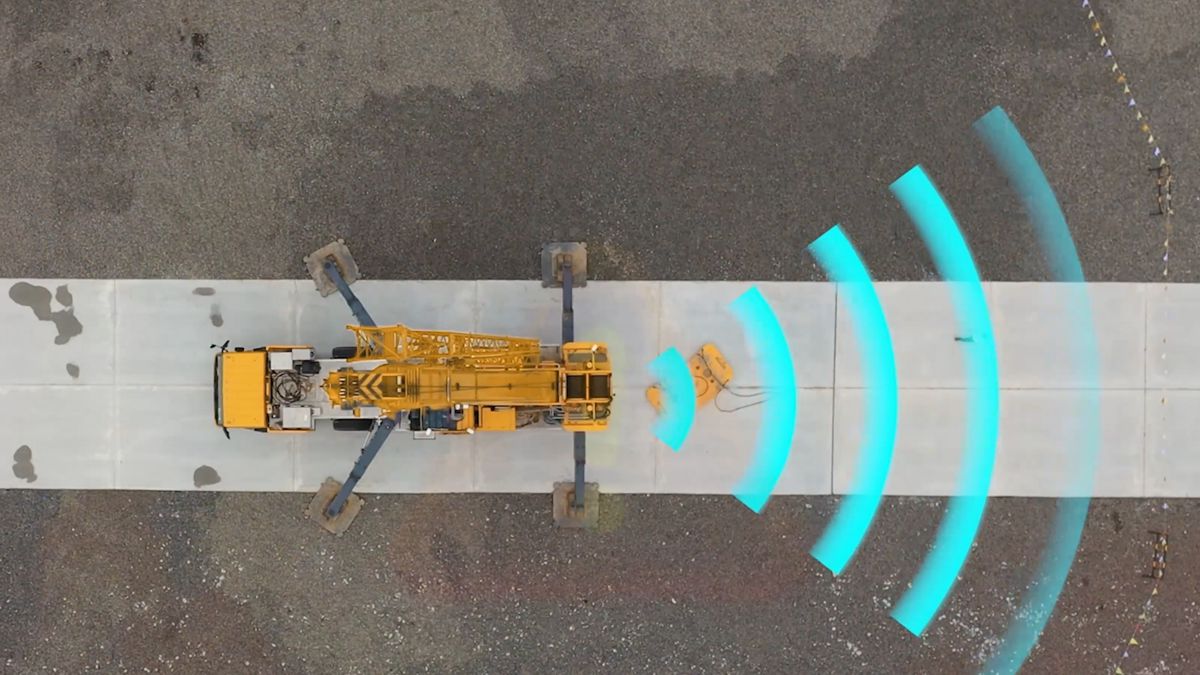

By using AI biometric, neural network algorithms, edge computing, and other technologies, biometrics-based warnings within a 30-meter radius of the operating equipment can be generated in real-time, effectively erecting a safety barrier for the operator and equipment.