Ionic Mineral Technologies scaling-up Nano-Silicon supply for Electric Vehicle Batteries

Ionic Mineral Technologies, a domestic advanced battery materials technology company, today emerges from stealth mode to debut its breakthrough halloysite-derived nano-silicon, Ionisil™, which can be used as a drop-in replacement for graphite in lithium-based batteries.

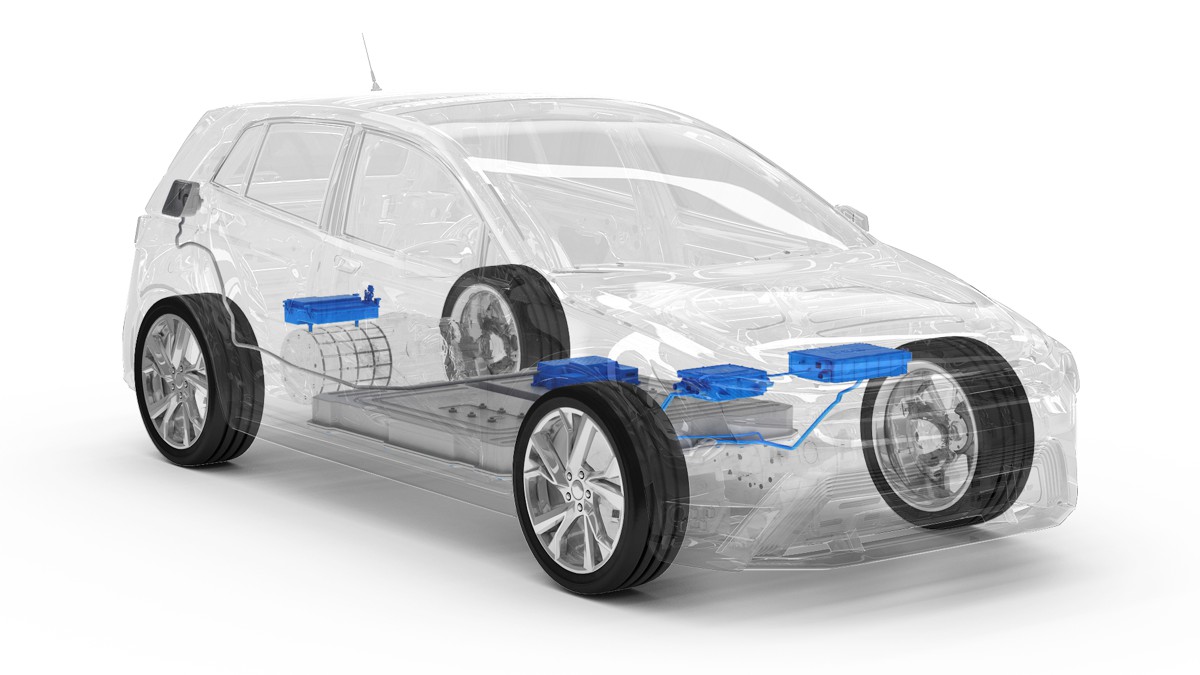

Nearly all automakers are seeking nano-silicon to unlock significantly longer range and faster charging for electric vehicles (EVs).

As the only vertically integrated producer of nano-silicon, Ionic MT is uniquely positioned to be a leading domestic supplier of nano-silicon and accelerate the electrified future. The Company controls the world’s largest deposit of high-purity halloysite, the ideal feedstock to manufacture nano-silicon at scale.

Halloysite’s naturally occurring nanotubular structure enables Ionic MT to employ a “top-down” approach to manufacturing nano-silicon, presenting significant scalability and environmental sustainability advantages compared to competitors.

“Halloysite-derived nano-silicon is a game-changer for the industry,” said Andre Zeitoun, founder and chief executive officer at Ionic Mineral Technologies. “At Ionic Mineral Technologies, we are the first to leverage this vast natural resource for the electric vehicle supply chain. With our approach, scalability is our advantage.”

“Ionic Mineral Technologies enters a hot market at an opportune time,” said Ram Chandrasekaran, head of road transport at global energy research firm, Wood Mackenzie. “With the demand for electric vehicle batteries expected to grow to over 3TWh by 2030, the need for next-generation battery materials is greater than ever.”

The Company launches just weeks after the Inflation Reduction Act (IRA) passed into law. The IRA’s EV tax credits hinge on domestically produced battery minerals, a largely non-existent supply chain. Ionic MT is positioned to address this ‘Achilles heel’ of the legislation and supply U.S.-sourced battery minerals and materials.

The Company will be exhibiting next week at The Battery Show in Novi, Michigan at Booth #3420, and CEO Andre Zeitoun will give a presentation, “Halloysite-Derived Nano-Silicon: Scaling Up from the Top Down,” in the Gold Ballroom on Wednesday, September 14, 2022 at 3 pm EST.

Ionic MT is operating out of its initial pilot plant and lab space, which includes a full battery testing lab, wet beneficiation of halloysite, and a patent pending, pilot-scale silicon production furnace to convert halloysite into nano-silicon.