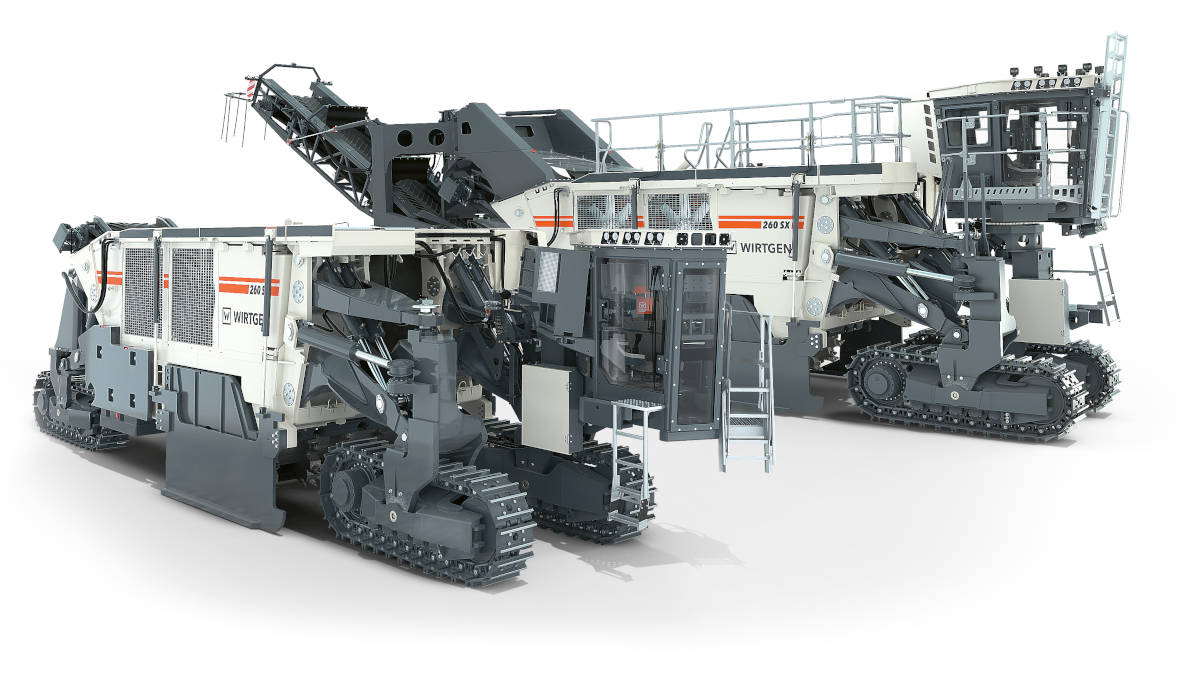

Wirtgen 260 SX(i) Cross-Application Miner designed for challenging projects

Whether for routing operations for railway projects, pipeline laying, or the construction of roads, tunnels, harbours, or water retention basins – cross application miners like the 260 SX(i) are the ideal choice for a multifaceted spectrum of applications and can powerfully, economically, and sustainably cut all types of rock.

Appropriate cutting drums for both hard and soft rock are available for the machine. In most cases, the extracted material is offloaded directly to road-legal construction site trucks with the machine’s integrated discharge conveyor.

Aside from performance, a particular focus in the construction of the machine was set on assuring high machine utilisation rates, as infrastructure projects often have to fulfil critical deadlines.

Environmentally compatible method for routing work and land-levelling

Routing work in solid ground, for instance on sandstone, limestone, slate, or granite, are frequently realised by drilling and blasting. The consequences of this method are strong shock waves, noise, dust pollution and a risk to health from toxic gases.

Restrictive environmental requirements with regard to noise and dust pollution and significantly higher costs for the procurement and handling of explosives make the method less and less attractive. The use of explosives is also not permitted in built-up areas.

In contrast, the 260 SX(i) excavates stone and rock by means of a cutting process. The machine cuts, crushes and discharges the material in a single operation to a width of 2.75 m and a depth of up to 650 mm. The process is almost vibration-free and causes only very little dust and noise pollution.

The process can therefore be employed in the immediate vicinity of buildings or buried utility pipes and cables. The 260 SX(i) cuts routes with a final profile and therefore saves the costs otherwise required for the processing of additionally excavated material and levelling.

Performance and precision in even the tightest spaces

Powered by a 30-litre, high-torque diesel engine with a rated power output of over 1,000 hp, the new machine always has sufficient reserves for the extraction of rock by cutting. The material can be directly offloaded into transport vehicles or deposited by either sidecasting or cut-to-ground.

Already successfully established in road construction and mining operations, the new LEVEL PRO ACTIVE levelling system is responsible for guaranteeing a consistently precise cutting depth. Its functions have been expanded with ergonomically designed control panels that make controlling the system intuitive and simple.

A turning radius of under 9 metres and the good manoeuvrability enable rapid turning manoeuvres, even in confined spaces.

A safe working environment

The 260 SX(i) is fitted with a dust-proofed positive pressure operator’s cabin with a fresh air filtering system, which effectively prevents dust entering the operator’s workplace. Apart from the comfortable operator’s seat, the cabin also provides an extra seat for a trainer for safe practical training of inexperienced operators on the machine.

The cabin also features an integrated, certified ROPS / FOPS system to ensure the protection of the operating personnel. When working at night, safe operation is assured by bright illumination of all relevant working areas on and around the machine.

The high-powered lighting system of the 260 SX(i) comprises LED floodlights for the working areas, lamps on the discharge conveyor and brightly illuminated access ladders and walkways. The operator’s cabin with all-round glazing is swivel-mounted on the front left chassis column and provides a consistently optimal all-round view of the working area and the material loading procedure.

An operating concept in line with the latest standards of ergonomics provides an ideal workspace that is an inviting aid to productive working with minimal stress and fatigue.

Cutting level surfaces and stable embankments

In the course of the cutting process, the 260 SX(i) produces precise, level surfaces that can be used directly as roads for construction vehicles or as foundations for routing work.

On the one hand, existing profiles copied by scanning the level of an existing surface using sensors installed on the side plate can serve as a reference for levelling. On the other hand, new profiling is also possible with the cross-application miner, for example, on the basis of a 3D terrain model.

Depending on the application, construction work can begin as soon as the desired profile has been produced. In road construction, for example, the surface cut by the machine provides an ideal base for the subsequent paving of surface layers.

During the cutting process, the machine enables the production of stable embankments with a predefined bank sloping angle – making another decisive contribution to safety and the minimisation of the need for additional excavation.

Tunnel construction

The construction of new tunnels or the lowering of the floors of existing tunnels often involves working in confined spaces and parallel to continuing rail traffic.

Blasting is rarely a viable option for loosening the rock. The cross-application miner enables the precise removal of floors with minimal vibration and the lowering of the tunnel profile to the desired level.

The height of the miner can be reduced for working in tunnels by mounting the operator’s cabin directly above the front left track unit. In this configuration, the machine also works using the cut-to-ground method, without a discharge conveyor and conveyor frame.

This means that the 260 SX(i) can also realise its full performance potential in narrow tunnelling situations.