How 3D Printing is improving Flexible Design in Construction

Construction and flexibility aren’t traditionally words that go together—particularly when you consider traditional building materials such as concrete and throw tight budgets, limited materials, and increasing transportation costs into the mix.

Most designers, engineers, and contractors are restricted by temporal, financial, functional, and aesthetic requirements. Yet, the secret to great construction design no matter your limitations is the quality of the materials used and technologies employed.

It’s no secret that the construction industry is under pressure to evolve. In November 2022, the European Commission called on all Parties to take urgent action to reduce greenhouse gasses, respect their commitments under the Paris Agreement, and limit global warming to 1.5 °C, meaning buildings need to be built well and sustainably. However, the industry’s rigid mechanisms and outdated processes are insufficient to achieve ambitious CO2 reductions while also meeting new consumer and building standards.

New solutions are needed to innovate the way and 3D printing (3DP) is one such technology with the potential for positive disruption. Although 3D printing dates all the way back to the 1980s, it has come a long way since then. Today, engineers can use almost any material and reduce labour, time, costs, and environmental damage with 3D printing technology, all while providing more design flexibility.

Sounds too good to be true? Let’s take a closer look.

More flexibility in the materials

Many engineers look to 3D printing to minimize waste since its additive manufacturing approach means only the necessary quantity of ingredients are used. As with all building projects, the quality and type of materials used define the overall construction’s durability, aesthetic, and character. One material that ticks nearly every box for engineers and contractors is concrete. Its resistance to extremely cool and hot climates, low cost, and widely-sourceable ingredients mean it’s an excellent material for a wide range of infrastructure projects.

However, current 3D printing methods rely on highly specialized and expensive materials, which is why in 2021, CEMEX introduced its proprietary admixtures family called D.fab with the world leader in 3D printing, COBOD. The duo’s revolutionary construction material enables the use of conventional concrete in 3D printing, providing reductions to both time and cost.

Moreover, today’s companies need to think outside the box and find ways to improve concrete blends and increase the use of recycled and waste materials such as mining waste, glass waste, mud, sawdust, and burnt clay. To create environmentally friendly, cost, and time effective concrete for 3DP machines, companies are introducing recycled waste glass into the cement production process and minimizing the use of limestone— the highest carbon-emitting element from the mix. 3D-printable zero-carbon cement and 3D-printable concrete and soil blends are both substances we will be seeing more of in the future. And as extreme weather conditions become more commonplace, we can expect to see more resistant 3D printing materials in the future.

More flexibility in the structural design

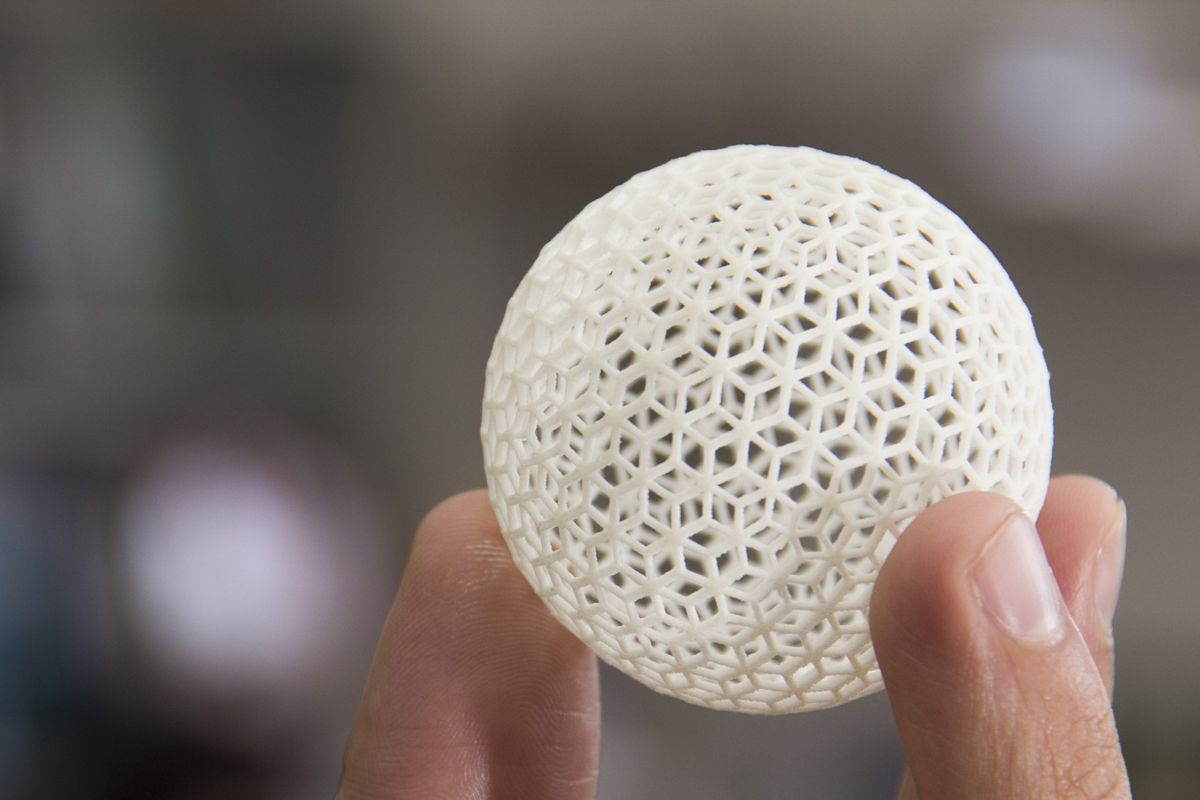

Reusability is vital for construction workers looking for sustainable ways to reduce waste and adapt to the high demand for building materials. 3DP, which removes the need for glues and binders, not only takes away the risk of adhesive debonding and sealing failures, but also increases the likelihood of being able to recycle products. It all comes down to smart structural design.

One 3D printing project with a powerful structural design is the Striatus bridge in Venice, Italy. The bridge consists of several pre-printed elements, manufactured in Switzerland and transported to Italy. The intelligent design mirrors a roman arch, with each component strategically placed to hold its form without additional support. What’s more? Its design uses zero adhesives, meaning unlike in traditional construction, it has the ability to be disassembled and reused in alternative locations.

Entirely 3D-printed projects allow engineers to design intricate details and structures that keep their form through precision rather than density. However, while 3DP concrete components can retain strength and durability when united, individually they are more susceptible to damage en-route. That’s why on-site printers will continue to play a larger role in construction, helping engineers to reduce the risk of damage and setbacks.

More flexibility in the aesthetics

Most building projects aim to use as many local materials as possible to minimize transportation costs and cut carbon emissions from lengthy and complicated supply chains. But what about local materials with an altogether new and disruptive aesthetic? This is where 3D printing is changing engineers’ and designers’ perspectives.

Clanwilliam cedar is one of the most endangered trees due to the extensive demand of its rot- and pet resistant timber and unique red and yellow colourings—which customers can choose between depending on their preference. But the future of construction must rely on alternative locally-sourced materials to avoid the overuse of traditional resources like cedar, while still maintaining consumers’ aesthetic demands. One example of how 3D printing is solving this dilemma is by employing local wood by-products such as sawdust. This stylish vine collection was 3D printed from the sawdust of previous builds. It used valuable by-products without any adhesives or extra connecting parts, ensuring that the end products were seamless, sustainable, and recyclable from start to finish.

Moreover, differently shaped 3D printing nozzles allow for different styles of brush strokes, curves, and angles. In fact, this technology can even recreate the appearance of multiple wood grains and reproduce these effects on recycled materials—in order to reduce our reliance on trees and other organic raw materials. The latest innovations in 3D printing can even add natural or vibrant tones to various grainless surfaces, expanding the capacity for experimentation, innovation, and style.

Beyond a shadow of a doubt, there is increasing pressure to innovate the industry with more sustainable materials, better structural designs, and new aesthetics. This is why engineers and designers should set their sights on 3D printing. This popular technology is alleviating previous restrictions and bringing flexible design to the world of construction.

Article by Ibon Iribar, Investment & Open Innovation Advisor at CEMEX Ventures.