Environmentally considerate Geotechnical Survey Drilling with Window Sampling

Geotechnical surveying investigations are never a one size-fits-all approach; there will always be varying situations and environments that call for several different approaches to be used effectively.

Large, open spaces, for example, will typically utilise drilling rigs, which are huge in scale with an unrivalled capacity, but with this they bring a sizeable environmental footprint. Narrower, restricted spaces, on the other hand, will tend to call for smaller rigs or hand operated tools – far more environmentally-conscious, but with a significantly diminished capacity.

As you would expect, there are several sampling methods which fit between both ends of the spectrum, yet window sampling comfortably sits above the rest. But what has been the driving force behind why this geotechnical methodology has become as popular as it is amongst drilling companies?

John Rodgman – managing director of the geotechnical drilling firm, Borehole Solutions – has shared his insight into this incredibly cost-effective drilling technique and the role it plays in working towards an environmentally-considerate future:

What is Window Sampling?

“Window sampling is primarily implemented in situations when geotechnical and environmental assessment is deemed necessary. It involves using a hydraulic drop-hammer to drive cylindrical rods and sample tubes (50mm-80mm in diameter) into the earth to form a borehole. In the side of these tubes, a square is cut out in the shape of a window. As the rods and sample tubes delve deeper into the ground, soil enters this opening, and once the required sampling depth has been reached, they are then extracted. Especially in less consolidated formations, however, care must be taken here to prevent the risk of borehole collapse.

“This cost-effective sampling method enables you to obtain high-quality, almost entirely undisturbed samples at a high degree of reliability within smaller scale investigations and those jobs which require a more environmentally conscious approach to be taken.”

What’s the difference between Window and Windowless Sampling?

“Where window sampling has sections cut out of the side of the tube to conduct soil sampling, should an instance arise where the core sample is required to be isolated due to the presence of contamination, for example, a uPVC liner system is used to extract the soil profile at its full length (either 1 or 2m), rather than the smaller samples collected through the window of the sample tube when conducting window sampling. This significantly reduces the risk of cross contamination when sampling.”

When is best to perform a Window Sample investigation?

“In ideal circumstances, this technique is used for smaller scale investigations, soil sampling, and in areas where site access is restricted. It is perhaps at its most effective, however, in sand and more cohesive formations where geotechnical investigations, chemical investigations, and contaminant logging are intended.

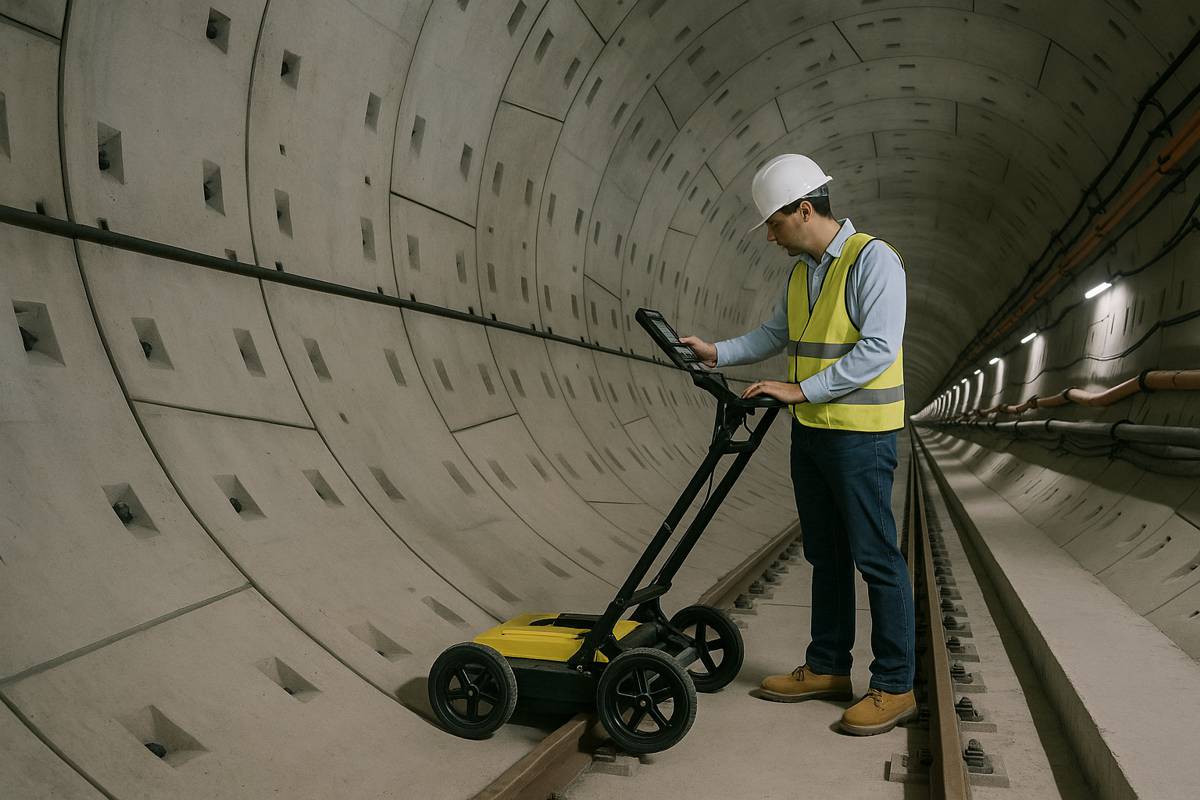

“Typically, the rigs you’ll employ during window sampling are highly manoeuvrable due to being mounted on rubber tracks, which when combined with their small and lightweight frames (these rigs tend to weigh somewhere between 150Kg and 200Kg), makes window sampling the ideal drilling technique for areas where environmental sensitivity is of the upmost importance.”

How does Window Sampling differ from other soil sampling methods?

“Where window sampling is primarily used on a smaller scale, rotary drilling suits projects both large and small. Rotary drilling is often used in quarrying and mining settings, as its rotary drill bit bores through rock with ease. This is similar to other investigative techniques – such as cable percussion, for example – which is versatile across consolidated and unconsolidated substrates.

“Deeper boreholes than window samplings 5m depth limit are possible, however shallow formations remain its speciality – offering high-quality sample results both economically, and whilst maintaining its environmental focus.”

The Benefits & Limitations of Window Sampling

“Of course, there’s a reason why this technique has become so popular amongst the geotechnical drilling sector. Primarily, it comes down to the fact that it remains cost-effective whilst still providing high quality, and almost entirely undisturbed samples. It requires minimal maintenance, and offers an incredibly high degree of reliability?

“As is the case with any other sampling or drilling method, however, window sampling does come with its drawbacks. Whilst its certainly a popular sampling method, it isn’t designed for coring in harder ground formations, and can typically only be used in shallow formations with a depth of up to 5 meters. It also requires two people to operate the rig safely, however, for most larger drilling companies, this isn’t an issue and is just something to keep in mind.”