Coal Mine Digital Elevation Models with the CHCNav AlphaAir 450

CHC Navigation (CHCNav) has shared with us the remarkable capabilities of their AlphaAir 450 LiDAR Aerial Survey Drone for creating highly accurate and detailed Digital Elevation Models (DEMs) for coal mine projects.

With the state-of-the-art technology, CHCNav aims to revolutionize the way elevation data is collected, processed, and utilized, ensuring optimal outcomes.

The AlphaAir 450

The AlphaAir 450 represents a significant advancement in airborne LiDAR (Light Detection and Ranging) technology. It is a sophisticated and versatile system meticulously designed to capture precise elevation data over large areas with exceptional speed and accuracy.

Combining cutting-edge sensors, advanced algorithms, and robust software, the AlphaAir 450 is perfectly suited to meet the demanding requirements of coal mine projects.

Unparalleled Accuracy

With the AlphaAir 450, CHCNav pushed the boundaries of accuracy in DEM generation. The system boasts a remarkable vertical accuracy of up to ±5 cm, enabling it to capture even the finest details of the terrain.

By providing highly reliable and precise elevation data, coal mine operators are empowered to make informed decisions with confidence, ensuring the safety and efficiency of their operations.

Rapid Data Acquisition

Time is of the essence in coal mining, and the AlphaAir 450 recognizes this need for efficiency.

Equipped with advanced scanning capabilities, the system can acquire vast amounts of elevation data at an unprecedented rate. Its high pulse repetition frequency and wide scan angle allow for efficient coverage of large areas in significantly reduced timeframes.

This means faster project completion, increased productivity, and improved overall project management.

Comprehensive Data Processing

Capturing the data is just the beginning. The AlphaAir 450 incorporates powerful data processing capabilities to extract valuable insights from the collected elevation data.

A team of experts developed state-of-the-art algorithms and software to meticulously process and analyse the raw LiDAR data, generating comprehensive Digital Elevation Models that accurately represent the topography of coal mine sites.

Advantages of Using DEMs for Coal Mine Projects

Digital Elevation Models offer a multitude of benefits when it comes to coal mine projects. By leveraging the precise and detailed information provided by DEMs, operators and engineers can optimize various aspects of their operations, resulting in enhanced safety, increased efficiency, and improved decision-making.

1. Site Planning and Design

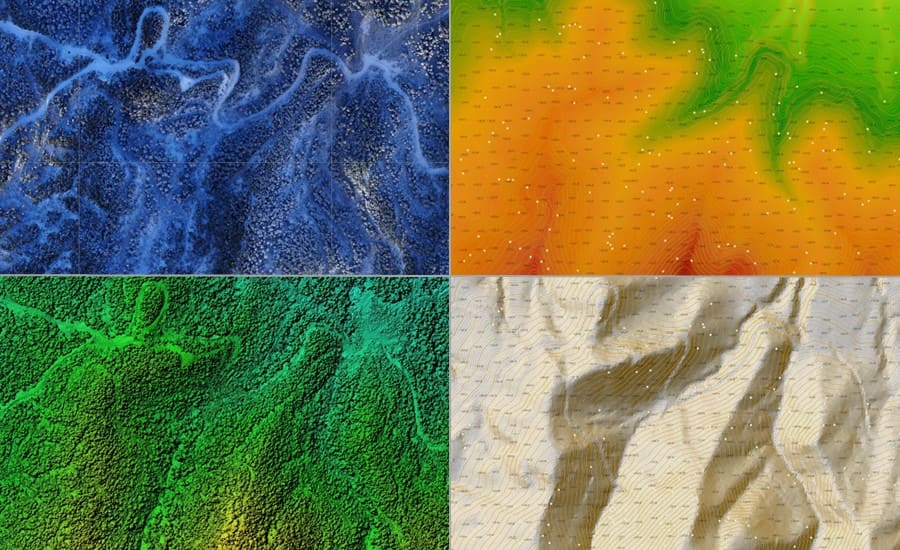

When planning a new coal mine project, having a thorough understanding of the terrain is crucial. DEMs provide detailed elevation data, allowing engineers to assess the topography and plan the layout of the mine accordingly.

By identifying potential challenges and optimizing the site design, operators can streamline operations, minimize risks, and ensure the most efficient use of resources.

2. Slope Analysis and Stability

The stability of slopes within coal mine sites is of paramount importance to prevent accidents and ensure the safety of personnel and equipment.

DEMs enable precise slope analysis by providing accurate elevation information. This allows engineers to identify potential areas of instability, implement appropriate measures, and maintain safe working conditions throughout the project lifecycle.

3. Drainage and Water Management

Water management is a critical aspect of coal mine projects, as excess water can disrupt operations and pose significant safety risks.

DEMs offer invaluable insights into the natural drainage patterns of the site, helping operators plan and implement effective water management systems. By understanding the flow of water and identifying optimal drainage channels, potential issues such as flooding or erosion can be mitigated, ensuring uninterrupted operations.

4. Environmental Impact Assessment

In today’s world, environmental considerations are of paramount importance in any industrial project, including coal mining. DEMs provide essential data for conducting comprehensive environmental impact assessments.

By accurately mapping the terrain and analysing the potential impact of mining activities on the surrounding ecosystem, operators can proactively develop mitigation strategies and ensure compliance with environmental regulations. This contributes to sustainable and responsible mining practices.

5. Haul Road Optimization

Efficient transportation of coal within a mine site requires well-designed haul roads. DEMs play a vital role in optimizing the layout and construction of these roads.

By analyzing the terrain’s elevation data, engineers can identify the most suitable routes, minimize the need for extensive earthwork, and reduce transportation costs. The precise elevation information provided by DEMs enables the creation of smooth and safe haul roads, enhancing overall operational efficiency.

6. Volumetric Calculations

Accurate volumetric calculations are essential in coal mining operations for inventory management and production planning.

DEMs enable precise measurement of stockpiles, excavation areas, and mine voids, providing operators with real-time data on the quantity of coal extracted. This information facilitates efficient resource allocation, helps monitor production targets, and enables effective decision-making throughout the mining process.

Optimizing Coal Mine Operations with AlphaAir 450

To illustrate the effectiveness of the AlphaAir 450 in coal mine projects, we looked at a case study that highlighted its impact on operational efficiency and safety.

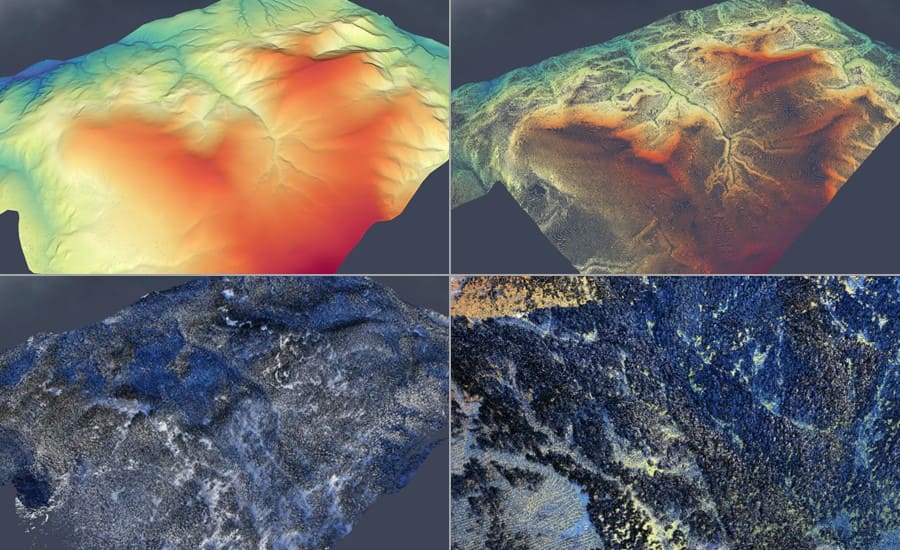

In collaboration with a leading coal mining company, CHCNav deployed the AlphaAir 450 system to survey and analyse a large coal mine site spanning several square kilometres. The objectives of the project were to create a highly accurate DEM, identify potential slope stability issues, optimize haul road design, and enhance environmental impact assessment.

Data Acquisition and Processing

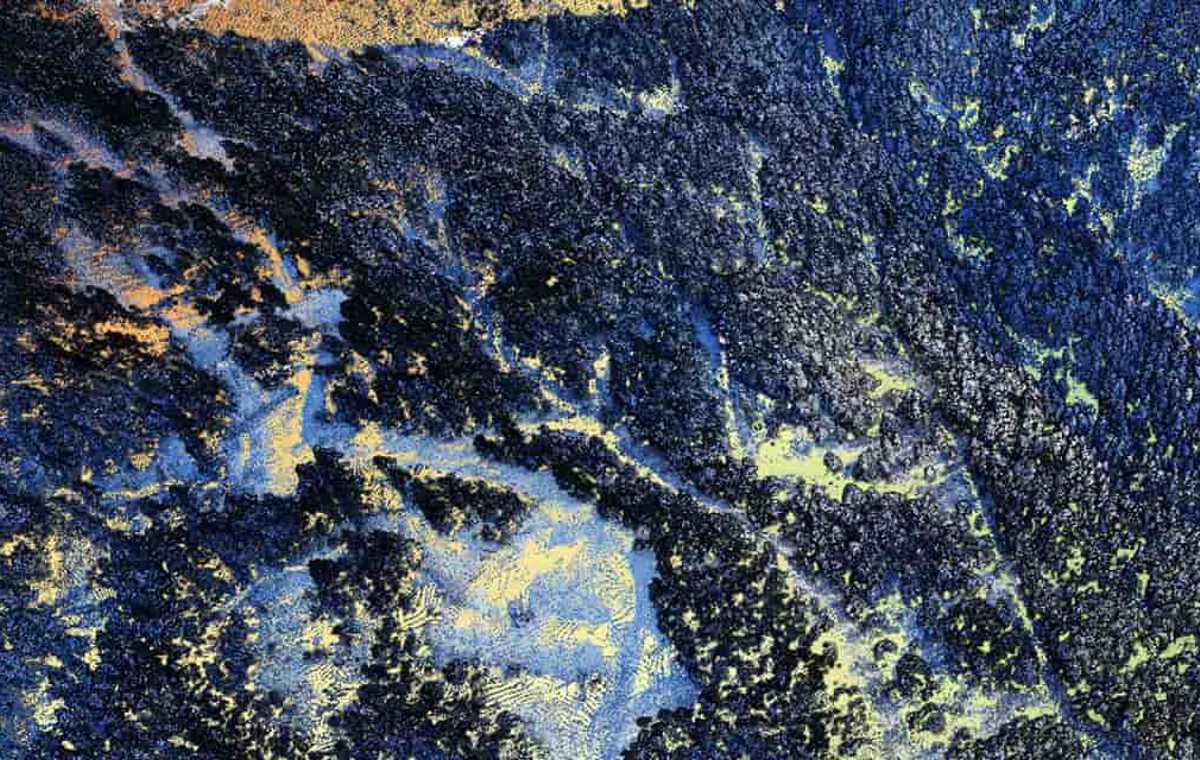

Using the AlphaAir 450, the project collected LiDAR data over the entire site, capturing millions of elevation points with remarkable precision.

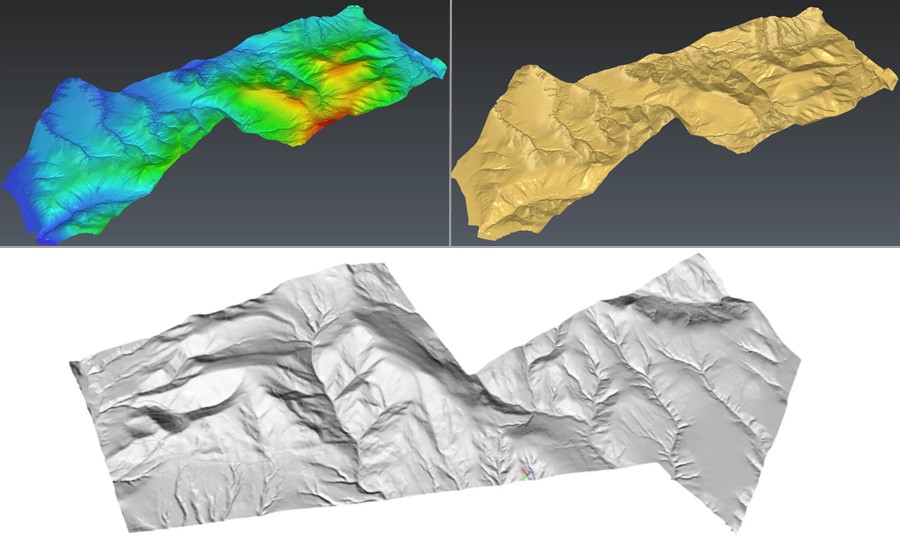

The collected data underwent meticulous processing and analysis, leveraging advanced algorithms and software specifically designed for DEM generation. This resulted in a comprehensive and detailed Digital Elevation Model, providing an accurate representation of the site’s topography.

Results and Benefits

The application of the AlphaAir 450 and the subsequent utilization of the DEM yielded significant benefits for the coal mine project:

1. Enhanced Safety

The detailed DEM enabled engineers to identify potential slope stability concerns and implement necessary measures promptly. This contributed to a safer working environment and minimized the risk of slope failures or accidents.

2. Optimized Haul Road Design

By analysing the elevation data from the DEM, engineers were able to design haul roads that minimized earthwork requirements and reduced transportation distances. This led to improved efficiency in coal transportation within the site.

3. Environmental Compliance

The accurate DEM facilitated a comprehensive assessment of the project’s environmental impact. By understanding the terrain’s characteristics, the mining company could develop effective strategies to mitigate potential environmental risks and ensure compliance with regulations.

4. Streamlined Operations

The precise volumetric calculations enabled by the DEM allowed for better inventory management, production planning, and resource allocation. This led to optimized mining operations, increased productivity, and improved overall project management.

The AlphaAir 450 represents a breakthrough in LiDAR technology, specifically tailored for coal mine projects. Through its exceptional accuracy, rapid data acquisition, and comprehensive data processing capabilities, it empowers operators and engineers to optimize their operations, ensure safety, and make informed decisions.

By utilizing the AlphaAir 450 to create highly accurate Digital Elevation Models, coal mine projects can benefit from improved site planning, slope stability analysis, efficient drainage and water management, comprehensive environmental impact assessments, optimized haul road design, and accurate volumetric calculations.

Setting new standards in LiDAR technology for coal mine projects

The AlphaAir 450 sets a new standard in LiDAR technology for coal mine projects with its remarkable accuracy, efficient data acquisition, and robust data processing capabilities that provide operators and engineers with the tools they need to optimize operations, ensure safety, and make informed decisions.

By harnessing the power of the AlphaAir 450 to create highly precise Digital Elevation Models, coal mine projects can unlock numerous benefits. These include improved site planning, enhanced slope stability analysis, efficient drainage and water management, comprehensive environmental impact assessments, optimized haul road design, and accurate volumetric calculations.

CHCNav are committed to delivering innovative solutions that drive success, and the AlphaAir 450, combined with mining industry expertise and dedication, empowers coal mine operators to achieve operational excellence, maximize efficiency, and uphold the highest standards of safety and environmental responsibility.

Contact CHCNav to learn more about the AlphaAir 450 and how our advanced technologies can revolutionize your coal mine projects.