Eaton supplying EV Battery Disconnect units for major global automaker

Intelligent power management company Eaton today announced its eMobility business has received a contract to supply its battery disconnect unit (BDU) in both 400- and 800-volt configurations to a global vehicle manufacturer for use in electrified passenger vehicles.

Eaton’s BDU integrates its Breaktor® circuit protection technology in electrified vehicles (EVs), which reduces complexity and cost. Eaton will be displaying this technology at The Battery Show in Stuttgart, Germany, May 23-25, 2023, and leading a discussion on functional safety in electric vehicle systems on May 25 at the conference.

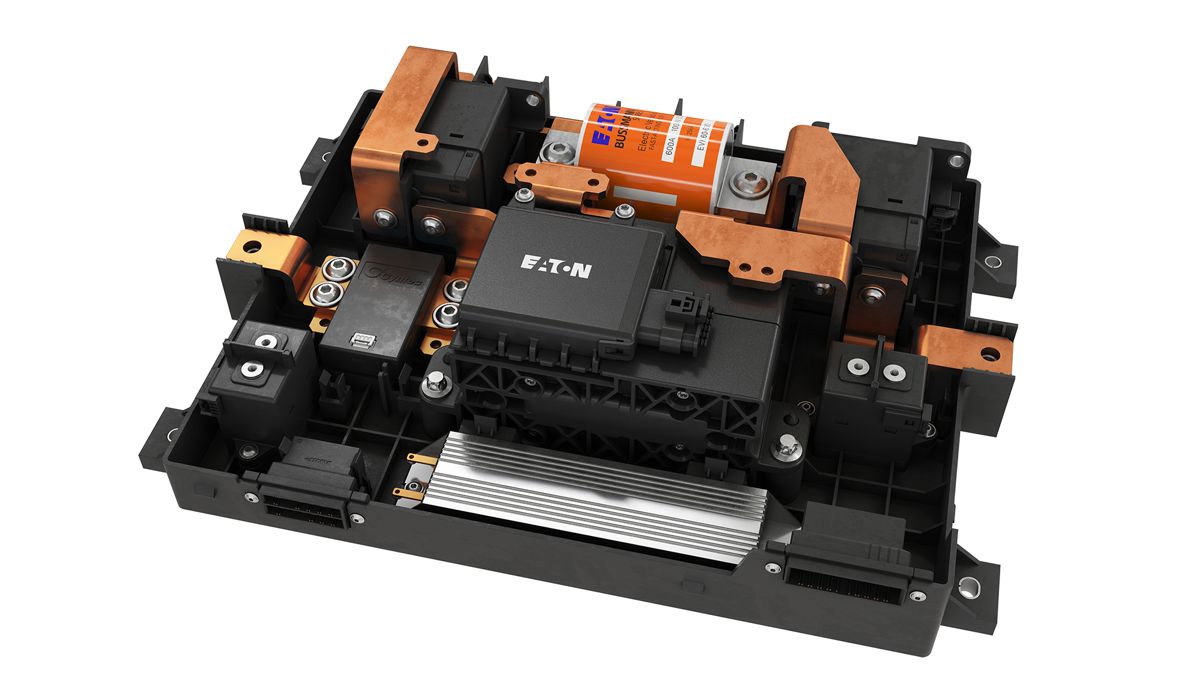

“We are excited to bring such a critical part of the EV system with industry-leading safety features and efficiency to this world-class vehicle manufacturer,” said Mark Schneider, president, eMobility. “Our BDU integrates our Breaktor® circuit protection technology, Bussmann™ fuses, and advanced Royal Power Solutions busbars to provide complete electrical protection for the EV system, in a compact and efficient package.”

The BDU’s primary function is to serve as an on/off switch to the battery depending on what mode the EV is operating in, such as charging or driving. Most of today’s EVs rely on one of three traditional circuit protection configurations in the BDU: fuse and contactor; pyro fuse and contactor; or fuse, pyro fuse and contactor all used together in a single BDU. While all provide switching and protection functions, they each have disadvantages, including overall system complexity, serviceability, coordination difficulties and susceptibility to fatigue under high current levels.

Adding Breaktor® circuit protection technology to Eaton’s BDU provides extra functionality and benefits, including replacing up to four high-voltage electrical components, which reduces complexity and system-level cost; active and passive actuation in a single device; and the ability to be reset after a high-energy fault. In total, Eaton’s BDU eliminates the need for up to 15 additional system components.

Innovative busbars with a low-profile enabling space-efficient design without heat sinks for weight savings were designed into the BDU. Eaton also leverages an automated assembly process to provide superior safety, reduce production time and offer maximum cost savings with little wasted material and nearly zero development time for production products. This power connections technology was designed by Royal Power Solutions, which Eaton acquired in 2022. Eaton’s Bussmann™ series fuses were also leveraged to ensure optimum BDU performance.

“With Breaktor and our Power Connections solutions, Eaton is uniquely positioned to create differentiated electrified vehicle solutions for its global customers,” Schneider said.