Thermal Conductivity of Materials tuned in real-time for more Energy-efficient Devices

A team led by University of Minnesota Twin Cities scientists and engineers discovered a new method for tuning the thermal conductivity of materials to control heat flow “on the fly.” Their tuning range is the highest ever recorded among one-step processes in the field, and will open a door to developing more energy-efficient and durable electronic devices.

The researchers’ paper is published in Nature Communications, a peer-reviewed scientific journal covering the natural sciences.

Just as electrical conductivity determines how well a material can transport electricity, thermal conductivity describes how well a material can transport heat. For example, many metals used to make frying pans have a high thermal conductivity so that they can transport heat efficiently to cook food.

Typically, the thermal conductivity of a material is a constant, unchanging value. However, the University of Minnesota team has discovered a simple process to “tune” this value in lanthanum strontium cobaltite, a material often used in fuel cells. Similar to the way a switch controls the flow of electricity to a light bulb, the researchers’ method provides a way to turn heat flow on and off in devices.

“Controlling how well a material can transfer heat is of great importance in daily life and in industry,” said Xiaojia Wang, co-corresponding author of the study and an associate professor in the University of Minnesota Department of Mechanical Engineering. “With this research, we have achieved a record-high tuning of thermal conductivity, showing promise for effective thermal management and energy consumption in the electronic devices people use every day. A well-designed and functioning thermal management system would enable better user experience and make devices more durable.”

Wang’s team worked in tandem with University of Minnesota Distinguished McKnight University Professor Chris Leighton, whose lab specializes in materials synthesis.

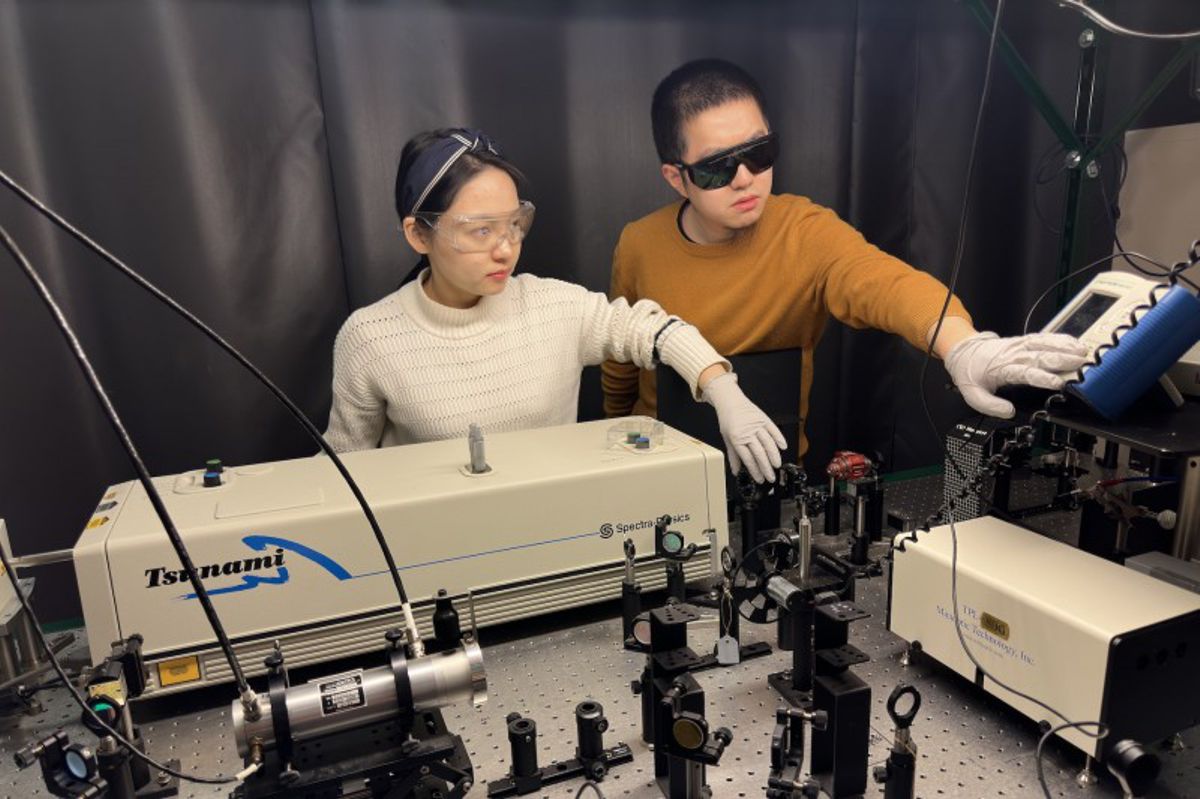

Leighton’s team fabricated the lanthanum strontium cobaltite devices using a process called electrolyte gating, in which ions (molecules with an electrical charge) are driven to the surface of the material. This allowed Wang and her research team to manipulate the material by applying a low voltage to it.

“Electrolyte gating is a tremendously powerful technique for controlling the properties of materials, and is well established for voltage-control of electronic, magnetic, and optical behaviour,” said Leighton, co-corresponding author of the study and a faculty member in the University of Minnesota Department of Chemical Engineering and Materials Science. “This new work applies this approach in the realm of thermal properties, where voltage-control of physical behaviour is less explored. Our results establish low-power, continuously tuneable thermal conductivity over an impressive range, opening up some pretty exciting potential device applications.”

“Although it was challenging to measure the thermal conductivity of lanthanum strontium cobaltite films because they are so ultrathin, it was quite exciting when we finally got the experiments to work,” said Yingying Zhang, first author of the paper and a University of Minnesota mechanical engineering Ph.D. alumnus. “This project not only provides a promising example of tuning materials’ thermal conductivity but also demonstrates the powerful approaches we use in our lab to push the experimental limit for challenging measurements.”

This research was funded primarily by the National Science Foundation through the University of Minnesota’s Materials Research Science and Engineering Center (MRSEC). Parts of the research were carried out at the University’s Characterization Facility and the Minnesota Nano Center.

In addition to Wang, Leighton, and Zhang, the research team included University of Minnesota Department of Mechanical Engineering Ph.D. student Chi Zhang; University of Minnesota Department of Chemical Engineering and Materials Science researchers William Postiglione, Vipul Chaturvedi, and Kei Heltemes; University of Utah, Salt Lake City researchers Rui Xie, Hao Zhou, and Tianli Feng; and Argonne National Laboratory physicist Hua Zhou.