Next generation of Flexible Magnetic Sensors boost performance

A giant leap of more than an order of magnitude improvement in the sensitivity of flexible magneto-resistive sensors heralds new opportunities for flexible sensors in medical devices, soft robotics and more

Flexible magnetic sensors have gained popularity due to their versatility and potential applications in major areas of flexible electronics, including soft robotics, consumer electronics, healthcare, automotive, and more. They are widely utilized for tasks such as navigation, strain and pressure sensing, posture and motion tracking.

A key advantage of flexible sensors compared to rigid ones, due to their bendability, is their conforming to a wide variety of surfaces including those that are soft and irregularly shaped. However, this advantage has come with a cost, as flexible magnetic sensors have exhibited significantly inferior capability of detecting small magnetic fields, which limits their potential use.

This may now change, as a group of researchers from Bar-Ilan University and Ben Gurion University has reported a giant leap of more than an order of magnitude improvement in the sensitivity of flexible magneto-resistive sensors.

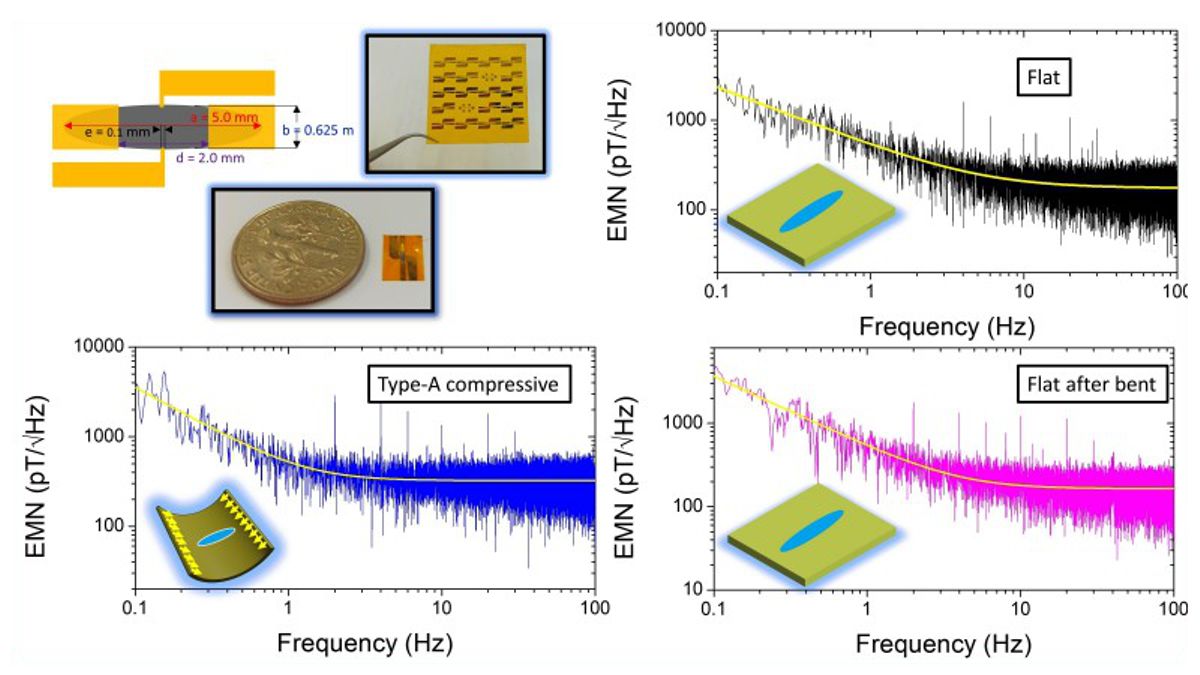

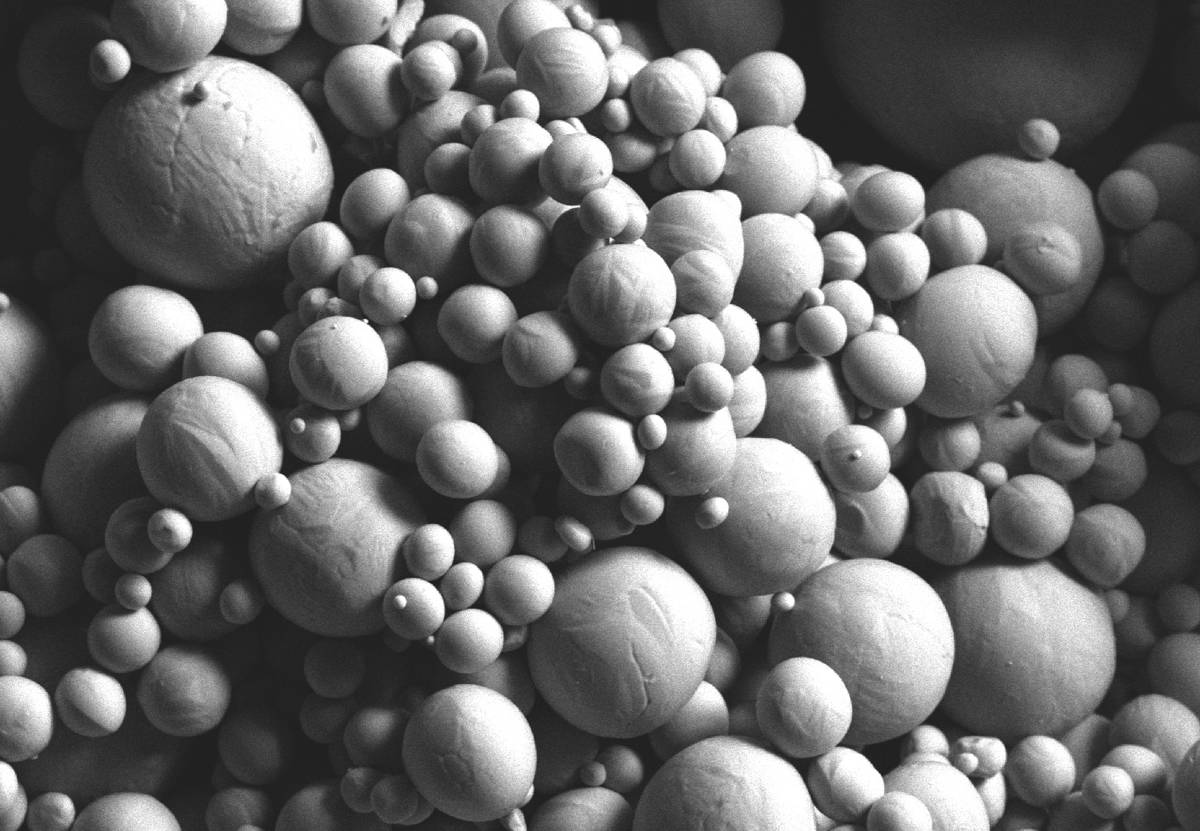

The sensors, elliptical in shape and grown on a polyimide tape, can detect low-frequency magnetic fields smaller than 200 pico-Tesla, which is more than 200,000 times smaller than the earth’s magnetic field. “These values are not only the best among all types of flexible magnetic sensors reported to date, but they also surpass those of many rigid counterparts,” says Prof. Lior Klein, of the Department of Physics at Bar-Ilan University, who led the research with Dr. Asaf Grosz from Ben Gurion University.

“The unprecedented sensitivity, accompanied by simple design, low cost and remarkable flexibility, make these sensors particularly attractive for being integrated in the next generation of flexible electronic devices.”

The recent development is reported in a paper co-authored by the group leaders, Dr. Hariharan Nhalil, Daniel Lahav, Shai Amrusi and Moty Schultz. The paper appears as an Editor’s Pick in the journal Applied Physics Letters.