The truth behind UK Construction Waste Compliance

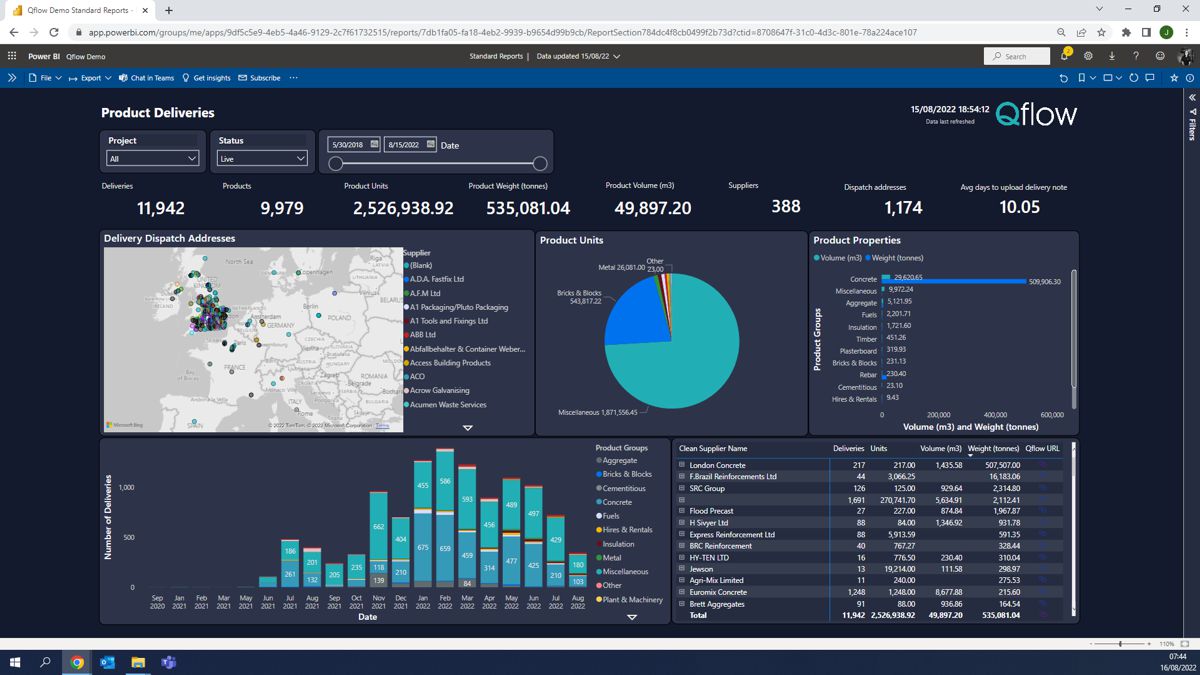

Qflow, a climate-focused construction tech company, released a comprehensive report analysing the state of waste management in the construction industry.

This industry-first report analyses over 90,000 legally required Waste Transfer Notes (WTNs) from June 2018 to April 2023, revealing a concerning average waste compliance rate of just 64 percent, meaning that one in three legally required fields go unchecked.

‘The UK Construction Industry Annual Waste Report 2023’ highlights that these omissions leave an incomplete picture of how waste is handled, where it is sent to, and what type of waste it is.

This lack of data makes it impossible to accurately quantify the cost involved and the physical waste produced in the process, and the resulting impact on our planet.

The Environment Agency is increasing its efforts to manage waste crime. Failure to produce complete documentation can result in a fixed penalty notice of £300 or prosecution and even imprisonment. If all the non-compliant WTNs analysed in this report incurred a fixed penalty charge, the resulting fines would exceed £13M.

Brittany Harris, Co-Founder & CEO of Qflow, said: “When we started this analysis, we knew it was going to highlight some pretty shocking practices, but I wasn’t prepared for this level of non-compliance! As an industry, construction consumes over 40% of the world’s raw resources and accounts for over 40% of landfill waste.

“Without good data on what’s happening to all this waste, we don’t have a chance of reducing it or improving material reuse and recycling. We hope that with the insights shared today, and by helping the industry get better data far more easily, we can work together with the regulators, industry bodies, developers and contractors to really transform construction from a linear and wasteful industry to one that is circular and low carbon.”

The report also uncovers the significant carbon footprint of waste management in construction. The average emissions associated with waste transport per project equates to over nine tonnes of CO2e, or more than 6,000 miles of travel. The current average carbon emissions associated with waste management during construction is 190 tonnes of CO2e per £1,000,000 of project spend.

Other key findings include:

- Average emissions associated with waste transport per project are over nine tonnes of CO2e, equating to more than 6,000 miles of travel.

- 93 percent of WTNs had missing facility permits/exemptions.

- 83 percent of WTNs had missing carrier licences.

- Seven percent had a missing EWC code (a six-digit code used to identify waste as listed in the European Waste Catalogue).

Ed Green, Sustainability Director at Grosvenor Property UK, explained: “Qflow’s waste report strikingly details the flaws in the construction waste sector, which have become apparent to us since we invested in and began using their platform. There are so many holes in the chain of custody that it’s hard for any developer, no matter how responsible, to reliably report on what is happening to 100 percent of its construction waste.

“It is of paramount importance that the entire industry takes responsibility and ownership of its waste cycle. Material circularity in the built environment can only be achieved when true accountability is taken for the waste from construction sites.”