Kleemann continues Sustainability drive for less noise and dust pollution

Excessive noise and dust emissions result in damage to health in the long term. To protect not only employees on building sites, but also human and animal life in the surrounding area, Kleemann continuously develops new measures for reducing and efficiently containing noise and dust emissions.

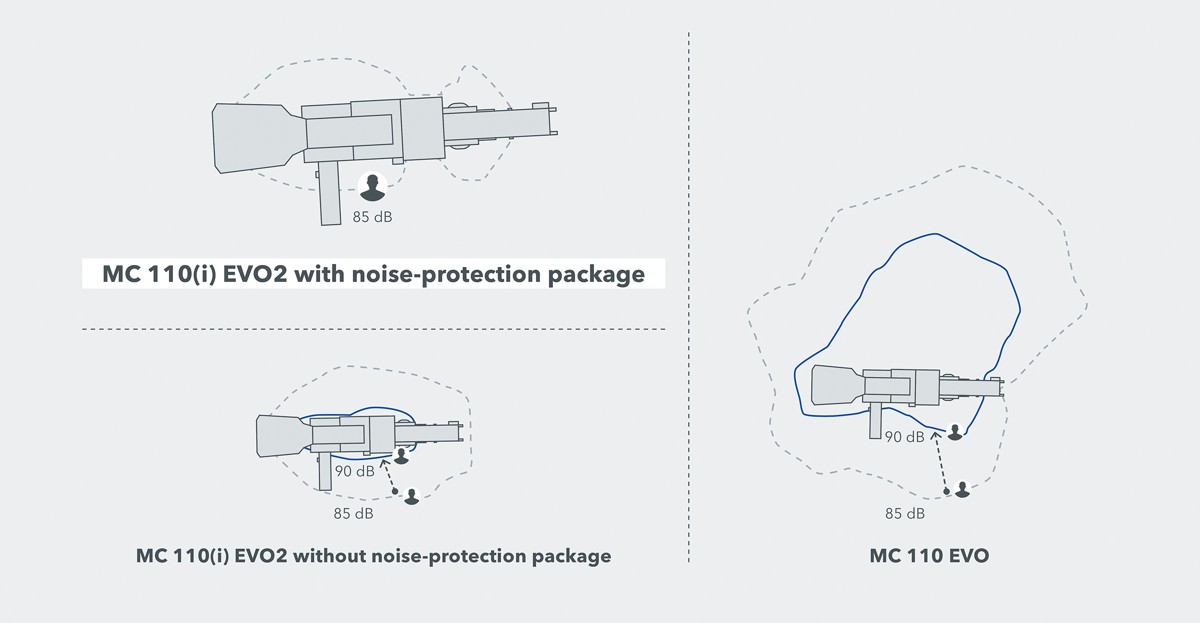

Kleemann machines of the latest EVO2 generation thus work with a lower sound power level than their predecessor models.

Less noise in urban areas

Particularly on building sites in intra-urban areas, many people are exposed to noise emissions. Comprehensive noise protection is therefore all the more important here. However, the regulations of local authorities with regard to the sound level on building sites are not standardised.

In order to optimise noise protection for residents and the building site team independently of this, in the past Kleemann has dedicated a lot of develop work into the emission reduction of its plants.

As a result, the basic versions of the current machines operate at sound power levels up to 6.2 dB lower than the predecessor models – the perceived noise is thus 75% lower. This is a clear improvement not only for users but also for residents.

Kleemann solutions

The standard version of the Kleemann machines of the latest EVO2 generation already operates at 87/88 decibels (dB) at the operator´s stand. Optional noise protection packages reduce the sound power level of the complete plant by a further 3 dB and halve the perceived noise level once again.

Categorisation aid: An average pneumatic drill reaches approx. 120 dB, a vacuum cleaner 70 dB.

Sustainability in the series

As the fan speed is regulated according to load, ambient temperature and degree of cooler contamination, even the basic configuration of the mobile jaw crusher MOBICAT MC 110(i) EVO2 is very low-noise.

With the additional noise-protection package, the plant can be operated without noise-damping headsets – depending on the ambient conditions and local regulations. Even without the noise protection package, only 90 dB are measured directly at the machine.

The noise protection package results in around 85 dB in the direct vicinity of the machine.

Effective dust containment

Not only efficient noise protection, but also containment of the dust development benefits employees, residents and the complete environment. This protects user and residents – and, ultimately, such measures also ensure greater acceptance of urban building sites.

Kleemann, with a special belt cover and a water spraying concept, has developed two measures that contribute to dust reduction. Water pump systems can be connected to the intelligently positioned water spraying system so that, among other things, standing water bodies or tanks can be used.

The cover means that the fine dust particles are no longer blown away but rather remain on the conveyor. The result is a clear reduction in dust emissions.