United States Steel Corp pioneers Battery-Powered Locomotives

United States Steel Corporation announced today a significant step in its ongoing commitment to sustainability, environmental excellence and the communities it serves.

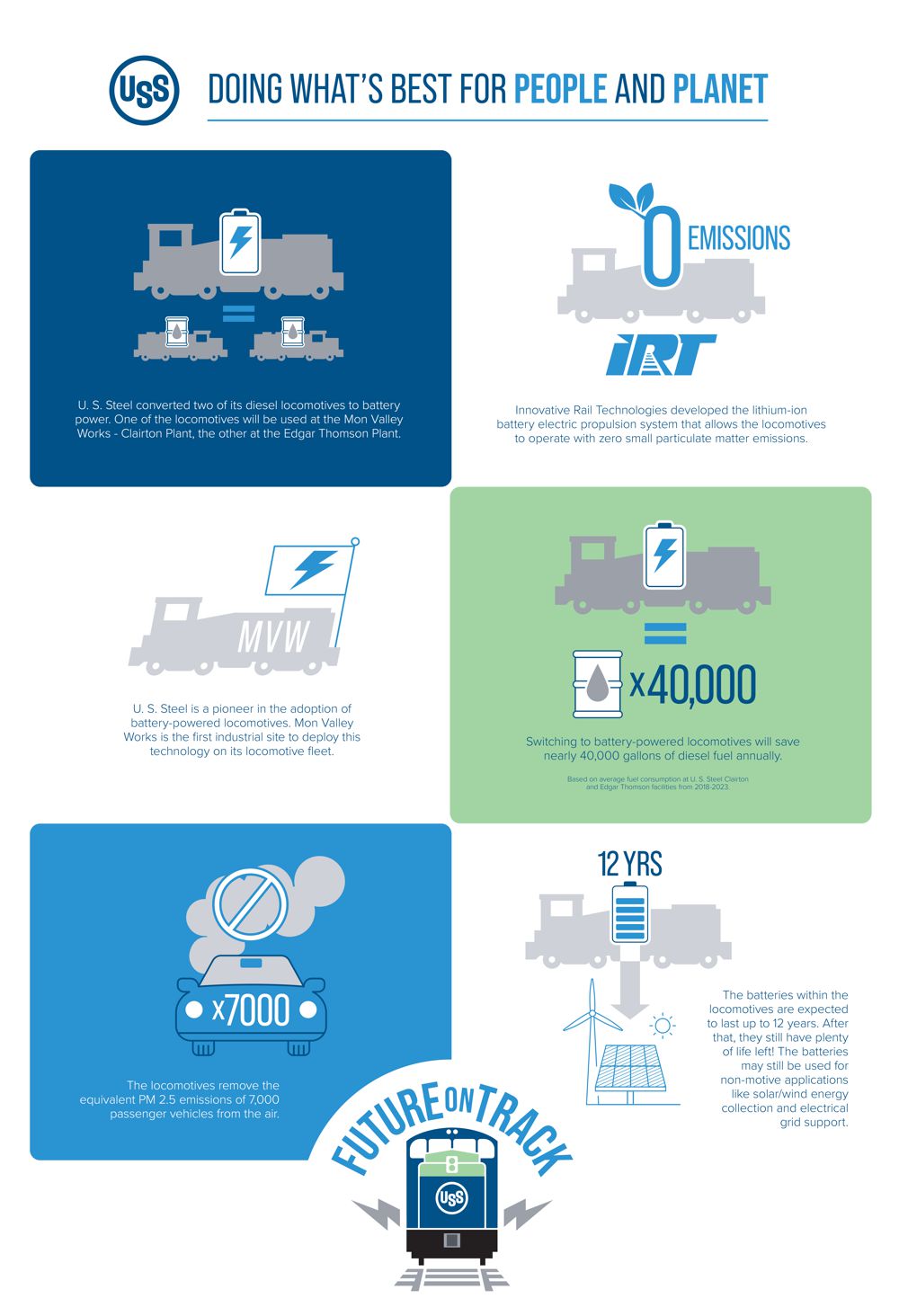

The company converted two of its diesel switcher locomotives at the Mon Valley Works’ Edgar Thomson and Clairton Plants to state-of-the-art battery-operated locomotives. The locomotives are built by Innovative Rail Technologies (IRT), a provider of customized lithium-ion propulsion solutions to the locomotive rail market. U. S. Steel invested more than $2.3 million in the locomotives while the remaining cost was offset through a partnership with the Pennsylvania Department of Environmental Protection (DEP).

The locomotives, which travel within the facilities carrying steel, coke, scrap metal, iron ore, and other materials necessary for production, are expected to reduce airborne particulate matter (PM2.5) emissions by .385 tons – the equivalent emissions of 7,000 gasoline-powered passenger vehicles.

“Mon Valley Works is the first industrial site to deploy this technology to reduce small particulate matter emissions from its locomotive fleet,” said Scott Buckiso, Senior Vice President and Chief Manufacturing Officer, U. S. Steel. “Advancing our Best for All® strategy means producing solutions that benefit our customers and communities, people and planet. This includes investing in technological advancements at our facilities.”

The switch to battery-powered locomotives will reduce the amount of diesel fuel consumed at the facilities by 40,000 gallons annually, reduce airborne particulate matter, and demonstrate the company’s use of emerging technology to help reach the goal of achieving net-zero emissions by 2050.

“We are proud to bring this innovative and sustainable technology to U. S. Steel’s Mon Valley Works,” said Ira Dorfman, Principal, IRT. “Battery propulsion technology is already in use throughout many modes of transportation, and rail transportation is the next step.”

U. S. Steel partnered with the Pennsylvania Department of Environmental Protection to utilize the agency’s Driving PA Forward – Marine and Rail Freight Movers Grant Program to offset the cost of the new battery-operated locomotives. The Driving PA Forward initiative improves air quality in Pennsylvania through the transformation from older diesel engines to cleaner technologies to help the state meet its diesel emissions reduction goals.

U. S. Steel unveiled the locomotives to the employees, members of the community, media, and elected officials at an event on October 30, 2023, at the Mon Valley Works – Clairton Plant.