Robotic Revolution advancing Nuclear Decommissioning safety at Sellafield

Sellafield’s deployment of robotic technology is achieving ground-breaking progress in nuclear decommissioning, with their insights benefiting the broader sector.

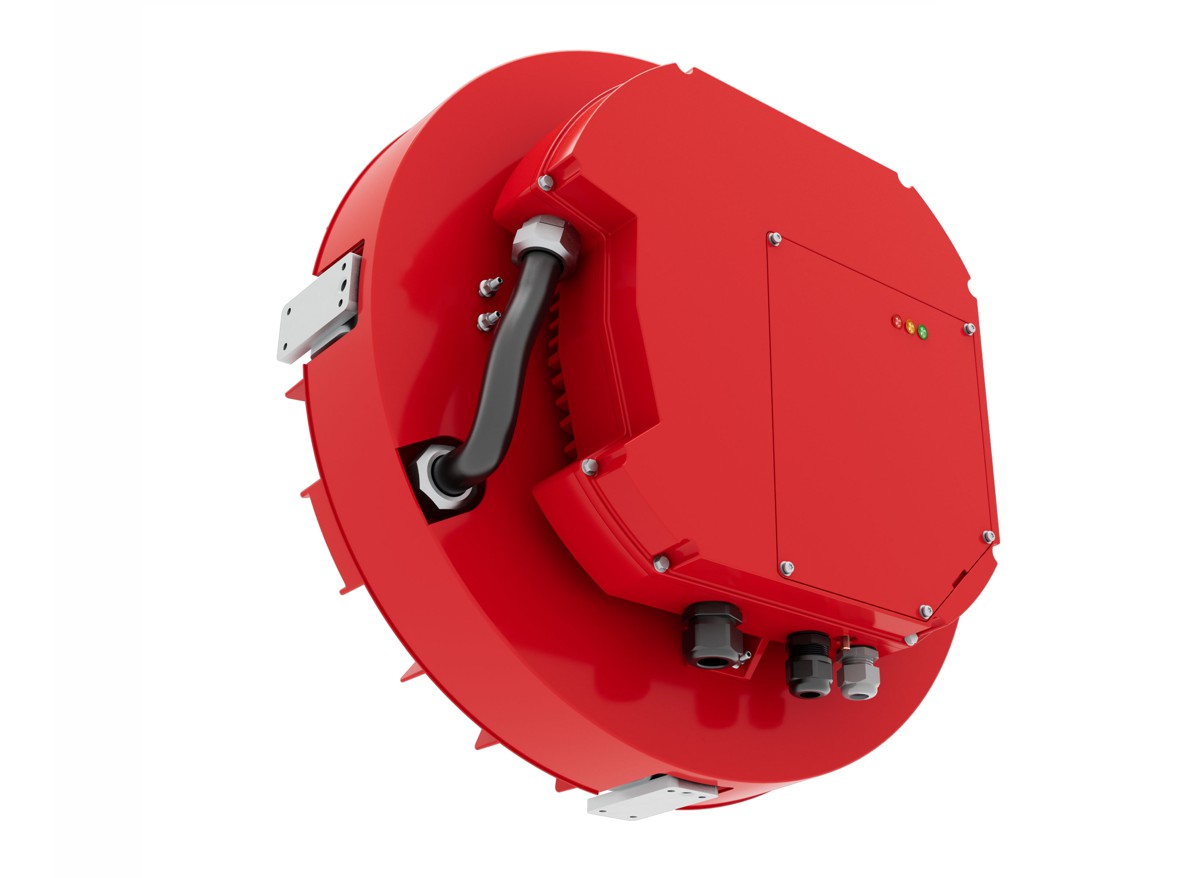

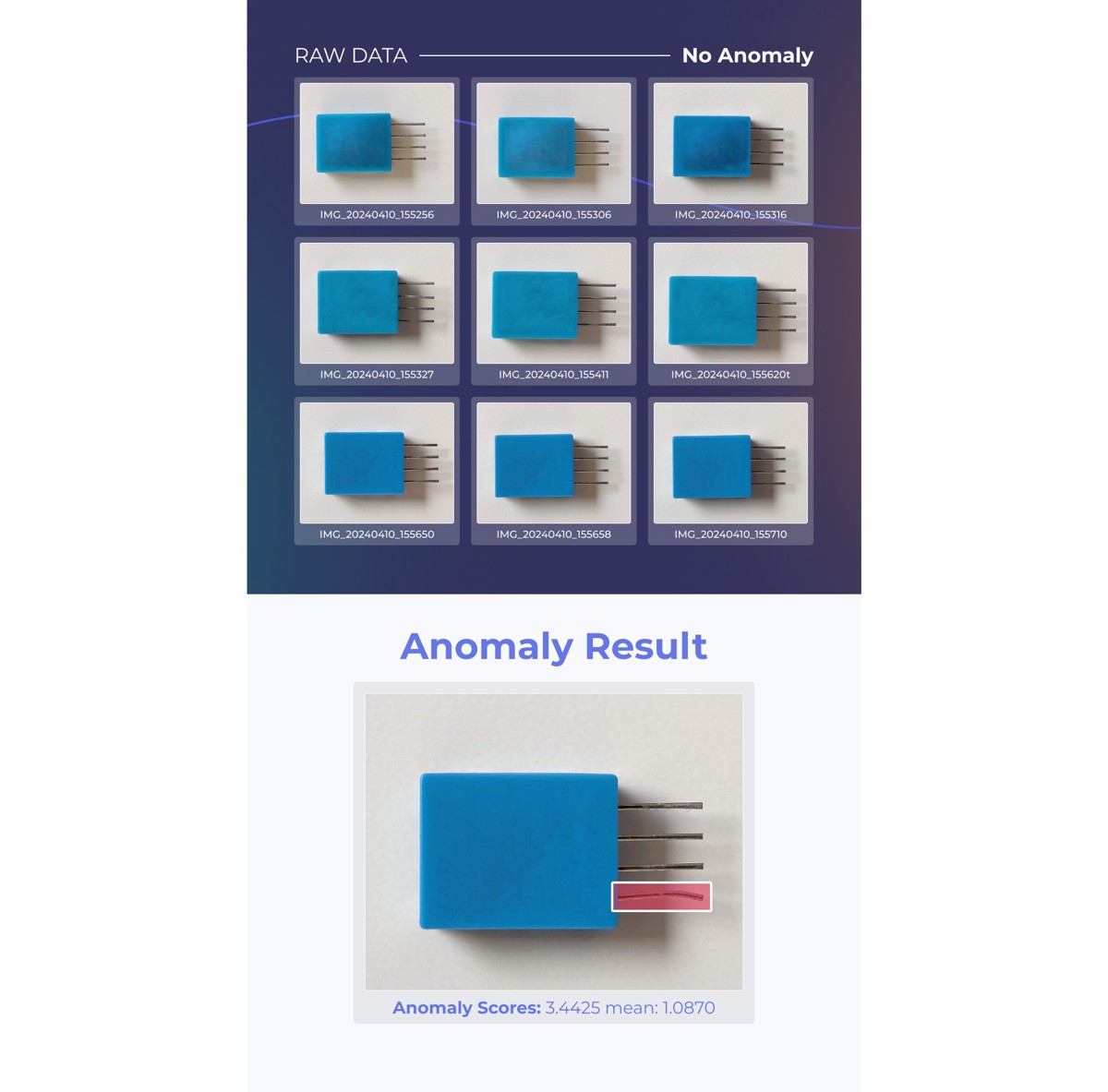

At the vanguard, Sellafield’s Engineering Centre of Excellence in Cleator Moor is redefining the application of standard robotics and software to meet unique on-site demands. The site’s recent innovation includes the world’s first adaptation of a LiDAR laser scanning device on a remote operated vehicle (ROV) within a high-radiation zone, thus pioneering a technique to visualize hazardous environments in 3D without exposing humans to risk.

Calvin Smye, ROV equipment engineer, said: “Everything we are using is off the shelf but by adding different payloads, like a LiDAR senor and a radiation monitor, we are adapting them to deliver for our business.

“Since the introduction of this technology we’ve really been at the forefront of testing it and adjusting it to our needs and are now leaders in the nuclear industry for applying it.

“We’ve seen supply chain colleagues deploying the same technology at other nuclear sites following our success.”

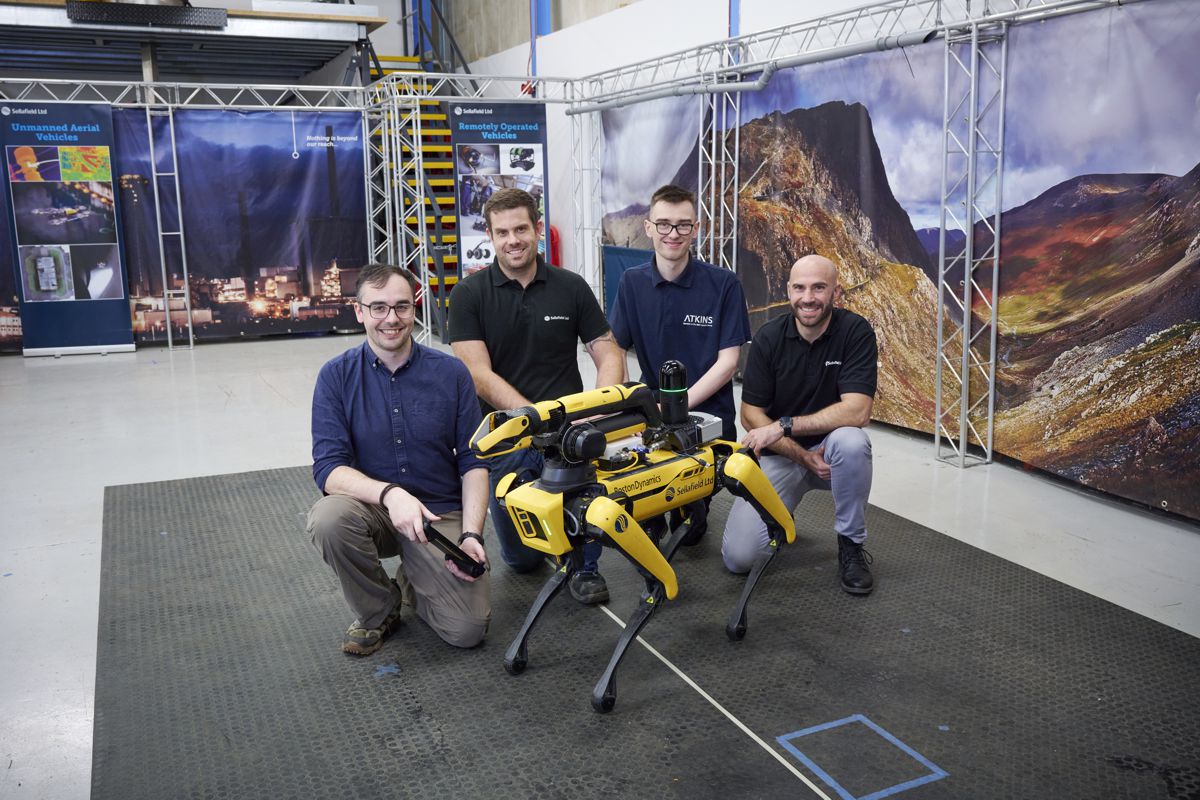

Spot, the robotic dog, has become an integral part of Sellafield’s operations, from building inspections to waste management. The robot’s functionalities were showcased during a live demo at Calder Hall, illustrating its capability to navigate areas with asbestos—a significant challenge in buildings from the 1950s.

The use of these robots has now extended to other UK Nuclear Decommissioning Authority (NDA) sites, such as Dounreay in Scotland.

Furthermore, Sellafield’s innovative efforts include deploying an IPEK crawler, traditionally used in sewer inspections, to evaluate the structural condition of pipelines. The organization is also exploring the potential of ROVs in gas detection, reminiscent of the historical use of canaries in coal mines.

Deon Bulman, ROV equipment programme lead, said: “The adoption of new technology is progressing at pace at Sellafield as people start to see the benefits. “

“The technology is here to support people, not replace them, and those that embrace it soon see the advantages.”

“If we can do one task that removes the need for a person to enter a hazardous area, that’s a win.”

Rav Chunilal, head of robotics and artificial intelligence, said: “The use of ROVs at Sellafield marks a significant milestone in our commitment to safety and efficiency.

“These cutting-edge robots allow us to access dangerous and challenging areas remotely, removing humans from harm’s way and saving time and costs for maintenance and inspections.

“By embracing remote technologies, Sellafield is pioneering a new era in the nuclear industry and setting a standard for excellence in decommissioning operations worldwide.”