Electrifying sustainability with Nouveau Monde Graphite’s Green Energy Leap

In line with its commitment to adopt clean energy sources and technologies, Nouveau Monde Graphite Inc. reports advancement on its electrification program for the Phase-2 Matawinie Mine and Bécancour Battery Material Plant.

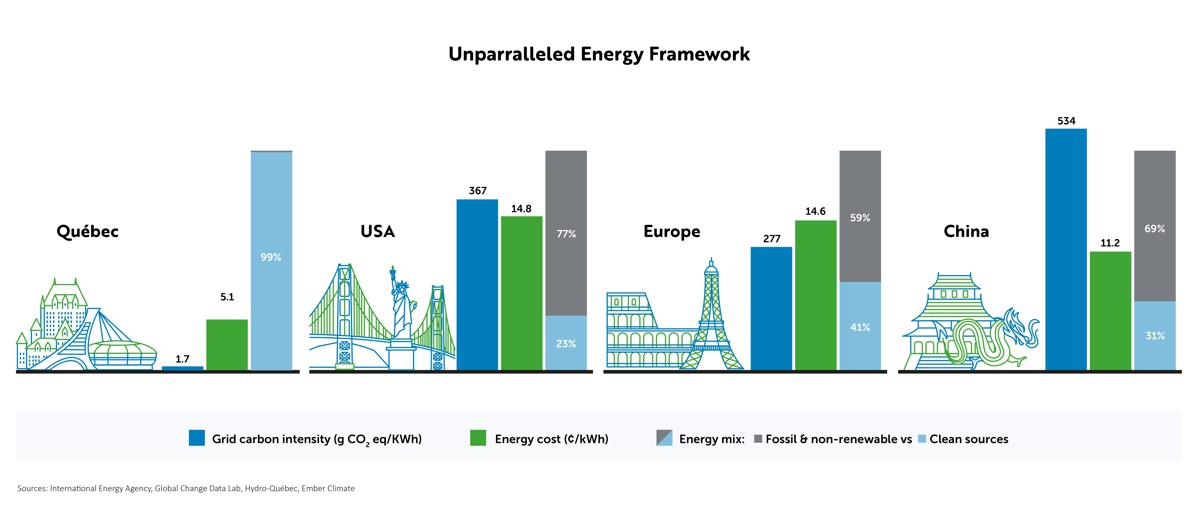

Leveraging Québec’s power grid, one of the greenest in the world, as the bedrock of its electrification strategy, NMG has confirmed electrical capacity and competitive rates, and defined zero-exhaust emission equipment deployment with Caterpillar Inc..

Arne H Frandsen, Chair of NMG, declared: “Clean energy is central to our operational, commercial, and ESG strategy. I am extremely pleased to see the progress made by our team and in collaboration with partners to translate our objectives into plans, technological design, and schedules. Québec is becoming North America’s green battery thanks to its vast hydropower network, and we, in turn, are leveraging this renewable energy and its multiple jurisdictional advantages to establish a new operational model, from ore to battery materials, fully electrified, fully integrated, fully traceable.”

Renewable Electricity Powering Clean Processing

Complementary to agreements in place for the Phase-2 Matawinie Mine which include the construction of a dedicated powerline, NMG obtained confirmation from Hydro-Québec – the government corporation that produces, transmits, and distributes electricity in Québec – of a 77 MW electricity block for the Phase-2 Bécancour Battery Material Plant. In the context of intense industrial development in the province, in part related to the expanding battery ecosystem, electricity allocations are now assessed on basis of technical connection capacities, economic and regional development benefits, environmental and social impact, and alignment with governmental orientations.

The allocated electricity block will enable the establishment of a fully integrated advanced manufacturing platform in Bécancour, in the heart of Québec’s battery valley, for refining graphite into active anode material.

NMG has received confirmation of its discounted industrial rate for hydroelectricity at both Phase-2 Matawinie Mine and Bécancour Battery Material Plant. Such favourable commercial electricity rate provides a cost-competitive environment for energy-intensive sectors such as mining and advanced manufacturing, an incentive for investment and continued upgrading of facilities, and operational visibility for the Company.

Electrifying Mining at Matawinie

Active technical work between Caterpillar and NMG’s teams have enabled the establishment of a calendar to deploy early learners and/or pilot models for the Phase 2 Matawinie Mine, to test equipment in actual terrain and weather, and to map the transition to future zero-exhaust-emission production models. The Cat® 950 GC-wheel loader would be the first battery-electric pilot machine to arrive at Matawinie.

These developments also support planning for the site’s charging infrastructure. Modelling and simulating the location of charging stations, equipment operations on site, as well as charging cycles in relation to operational schedules and the mining plan, help optimize site design and technology choices. The simulation of charging needs helps identify peak power demand and defining energy management strategies.

Denise Johnson, Caterpillar Group President, commented: “The Matawinie project highlights the complex questions miners are faced with when determining the amount of energy required to run a fully electric site. This is part of the learning NMG and Caterpillar are navigating together as we work through the realities of supporting the mine site of the future. I’m proud of the work our teams are accomplishing together to propel this project forward.”

Eric Desaulniers, Founder, President and CEO of NMG, said: “It started with a bold vision. Going all-electric at our Matawinie Mine is the way to go; environmentally to limit our carbon footprint, socially to rally the community behind a new mining development and to reduce the sound level of our operations, and commercially to engage with battery/EV manufacturers and tap into consumers’ responsible purchasing desires. Now, Caterpillar is providing us with a comprehensive solution, de-risking the adoption of new technologies and optimizing operational excellence through integrated infrastructure.”

Through definitive agreements signed earlier this year, Caterpillar is set to be NMG’s supplier of heavy mining equipment, supporting the progressive transition from traditional models to Cat® zero-exhaust emission machines as they become available. Moreover, NMG and Caterpillar signed a non-binding memorandum of understanding to advance commercial discussions targeting NMG’s active anode material. Hence, a full circular value chain could be established whereas NMG would supply carbon-neutral graphite materials to Caterpillar for the development of its secure, resilient, and sustainable battery supply chain that would serve to electrify heavy vehicles, including NMG’s Matawinie fleet.

Clean Energy to Support Decarbonization

Québec’s energy grid is among the greenest in the world. Hydro-Québec generates over 99% of its electricity from renewable energy sources, mainly through hydroelectric generating stations, for an emission factor of 0.6 kg CO2 eq/MWh (Hydro-Québec, 2021).

NMG’s confirmed capacity to tap into this electricity network provides a solid foundation for deploying new equipment and proprietary technologies with a view to produce advanced materials with a very low climate change impact, in line with global decarbonization efforts. An independently conducted cradle-to-gate life cycle assessment for the Company’s portfolio of graphite-based materials, confirmed the minimal and industry-leading environmental footprint of its production. NMG’s full commercial-scale Phase-2 all-electric facilities are forecasted to produce active anode material for lithium-ion batteries with a Global Warming Potential of 1.23 kg CO2 equivalent per kg, an impact up to 11 times smaller than that of benchmarked production.

Advancement of electrification initiatives aligns with NMG’s objective of reaching Net Zero by 2030 as detailed in the Company’s Climate Action Plan. NMG has placed environmental stewardship at the heart of its business strategy. Maintaining a carbon-neutral footprint and bringing to market Net Zero products provide a competitive advantage in the battery and electric vehicle sector as manufacturers actively seek to reduce their Scope 3 emissions, comply with regulatory requirements, and respond to consumer demands for sustainable, responsible production.