Robotic LaserWeeder upgraded to evolve Agriculture

Carbon Robotics today announced the Track LaserWeeder, a new model of its proven LaserWeeder, and two software enhancements: spatial data intelligence in the Carbon Ops Center and multi-language support in the iPad operator app.

By incorporating these advancements, Carbon Robotics not only addresses the diverse needs of farmers in various regions but also empowers them with actionable farm data, aligning seamlessly with the evolving demands of agriculture.

“We are excited to introduce the new Track LaserWeeder unit and software upgrades that will further improve the efficiency and capabilities of our industry-leading LaserWeeder for growers,” said Paul Mikesell, CEO and founder of Carbon Robotics. “Our customers laser weeded for more than 50,000 total hours last year across more than 100 different crops, capturing major savings in weed control costs and reporting substantial increases in crop yield and quality.”

The Track LaserWeeder offers a custom track system built in collaboration with Soucy and GK Machine and was designed with growers to extend the LaserWeeder’s usability across diverse soil types, including muck soil. By equally distributing the LaserWeeder’s weight, the tracks minimize compaction and allow the machine to enter fields earlier in the season despite challenging conditions. The first Track LaserWeeders are complete and staged for delivery beginning in March 2024.

“Custom tracks extend the versatility and flexibility of the LaserWeeder and open up laserweeding to more regions and farms with varying soil types,” said John Mey, vice president of product at Carbon Robotics. “By improving ground pressure to 6.5 p.s.i. and supporting row spacing of 64” to 90”, growers in muck regions now can use LaserWeeder to do the work of a 75-person hand weeding crew, have an alternative to herbicides, and gain the production benefits resulting from no soil disruption.”

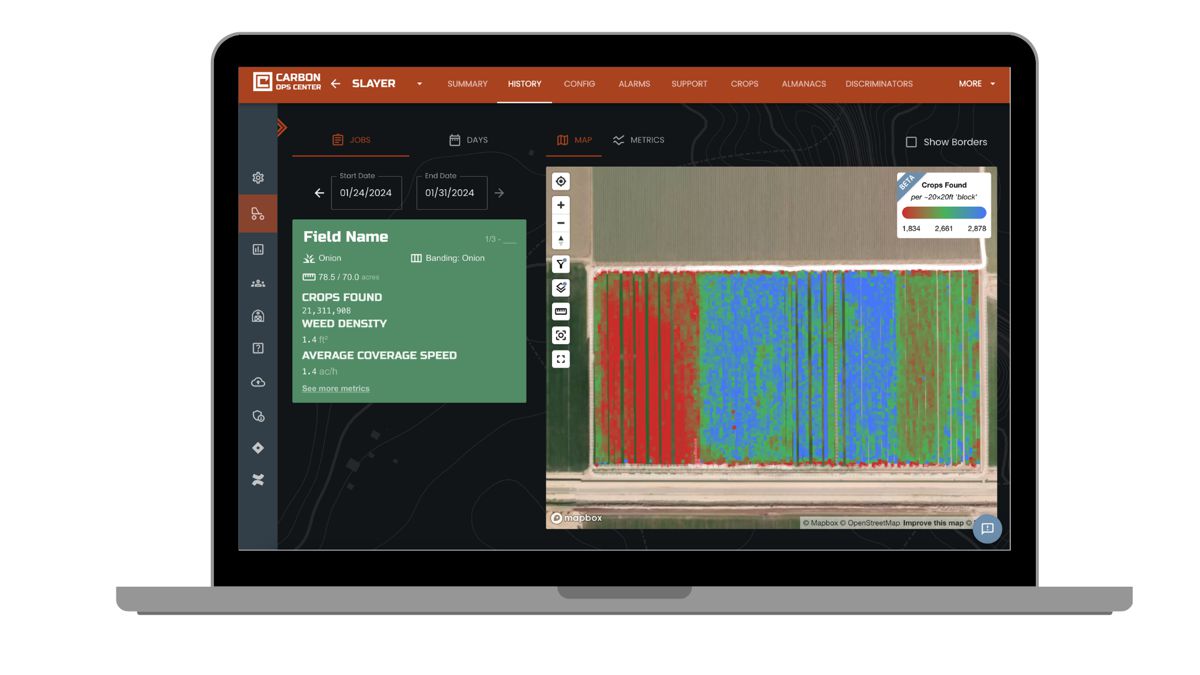

Carbon Robotics also introduced visualized spatial data available to all LaserWeeder customers. This innovative offering allows growers to access field, crop and weed metrics using the Carbon Ops Center, including stand count, density, type, average size and distribution.

This data allows growers to identify and address areas with inconsistencies or surprising results and provides them with quantitative crop stand counts early after planting and well before harvest.

Carbon Robotics has also incorporated multi-language support into its intuitive iPad operator app, now supporting seven additional languages, including Spanish, French, German, Danish, Dutch, Polish and Romanian. This feature allows field operators to utilize the app, alerts, and Carbon support more effectively by reducing language barriers.

2023 was a record year for Carbon Robotics, with a tripling number of LaserWeeders shipped to growers and rapid expansion into Europe and Australia. To support continued growth and rapid new product development, Carbon Robotics raised $43 million in new capital in 2023, bringing its total funding to $80 million since its founding in 2018.