Detecting Structural Cracks with Circular Vibration Mode Ultrasound

A high-efficiency circular vibration/polarization ultrasonic conversion technology capable of detecting cracks, which can occur in various directions within a structure, has been developed for the first time in the world.

For the first time in the world, the joint research team led by Senior Researcher Min-woo Kweun of the Department of Nano Devices & Displays of the Korea Institute of Machinery and Materials (President Seok-hyun Ryu, hereinafter referred to as KIMM) and Distinguished Professor Yoon Young Kim of the Department of Mechanical Engineering of the Seoul National University (SNU) College of Engineering (Dean Yoo-seok Hong) has succeeded in developing a metamaterial which is theoretically capable of completely converting the linear vibration of ultrasonic waves into circular vibration and has a three-dimensional microstructure.

The team announced the outcome of this research on “Nature Communications,” a renowned international science journal.

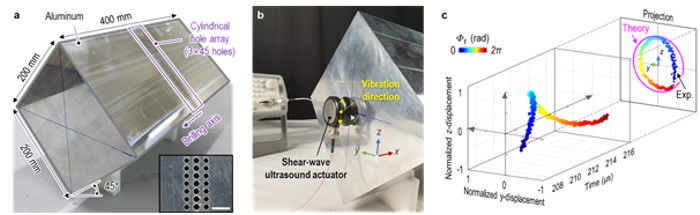

The joint research team of the KIMM and SNU first identified the unique anisotropic physical properties of the ultrasonic medium that converts the easily generatable linear vibration mode ultrasonic waves into circular vibration mode ultrasonic waves which has been more difficult to generate. Then, a metamaterial that satisfies this feature was designed by arranging a microstructure that has three-dimensional cylindrical holes. The joint research team then successfully measured the converted circular vibration mode ultrasound by conducting ultrasonic experiments.

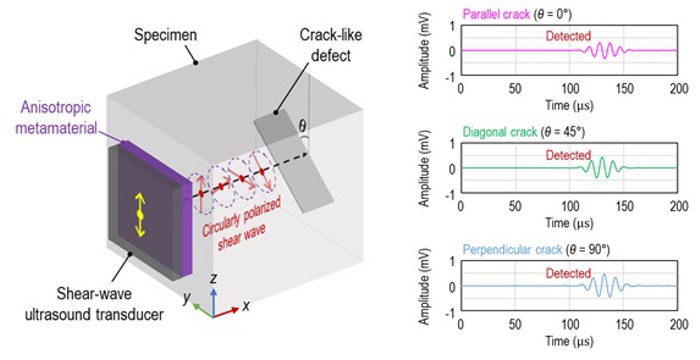

Linear vibration mode ultrasound, which is commonly known as shear ultrasound, is widely used for ultrasonic non-destructive testing to detect weld defects and plate defects. However, in cases where the direction of the defect is parallel to the direction of the linear vibration, the reflectivity of the defect in ultrasonic waves becomes extremely low, making it difficult to detect the returning ultrasonic signal.

On the contrary, the newly developed technology using metamaterials is, in theory, capable of completely converting the linear shear ultrasonic waves into circular shear ultrasonic waves. Moreover, as a small number of simplified cylindrical microstructures and low-loss metal materials are used for producing these metamaterials, it is possible to generate circular vibration mode ultrasonic waves with substantially high efficiency.

Senior Researcher Min-woo Kweun of the KIMM was quoted as saying, “We have developed a new ultrasonic mode capable of further improving the defect detection functionality of existing ultrasonic technologies.” He added: “We will make our utmost efforts so that this new technology can be used in the fields of industrial ultrasonic non-destructive testing and ultrasound imaging in the future.”

Meanwhile, this research was conducted with the support of the “Global Frontier Project – Center for Advanced Meta-Materials” sponsored by the Ministry of Science and ICT, and the “Global PhD Fellowship Program” sponsored by the Ministry of Education.