Mammoet showcases sustainability on Tunnel Section Transport Project in Belgium

What began as a standard skidding operation became a unique opportunity for Mammoet to demonstrate how it could lower the carbon impact of civil projects while still keeping disruption to a minimum.

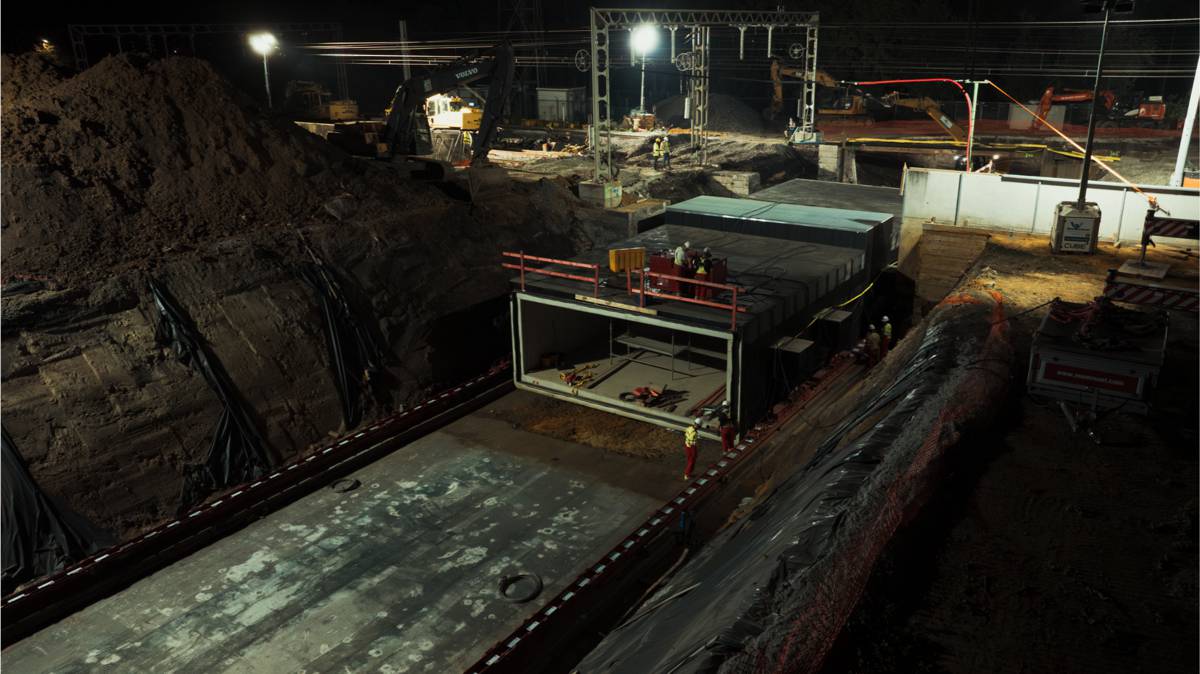

When Mammoet was approached by STADSBADER CONTRACTORS to lift and skid an 850t concrete tunnel section 40 meters underneath railway lines in Belgium, it assessed that the project could be achieved with zero emissions.

So, its engineers set to work combining existing skidding equipment with new battery-powered technology.

Planning for power

The project required precise calculations and implementation to lift and skid the 850t tunnel section, measuring 25m x 8.5m, across 40 meters to reach its destination: below a railway track near Brussels.

The operation also had to be carried out to a time-critical deadline, with minimum disruption to train users and before the Monday morning commute began.

Using Mammoet’s specialized tunnel adaptors and skidding system, hydraulic jacks were put into place to manoeuvre and lift the concrete tunnel section from the ground.

When enough ground clearance was created, hydraulic cylinders pushed the tunnel section across 40 meters of Teflon pad-equipped skid tracks to its destination.

The hydraulic power used to achieve this was generated using an electric powerpack, combined with a battery, to supply the power needed.

To determine what was needed to carry out the job, Mammoet engineers executed several smaller scale projects, such as transformer installations, which served as feasibility tests before moving on to the large-scale Belgian project.

After preparations for the operation were put in place, the skidding procedure was completed in under an hour and 2.5 hours ahead of the estimated schedule.

The electric powerpack, or Mobile Power Unit, is powered by recycled batteries, with a maximum capacity of 50kWh. It weighs 1,460kg and has loading capacity for an additional 1,000kg of auxiliary equipment via its roof rack. It accepts standard inputs and outputs at 16, 32 or 63A.

Its battery can also be charged using solar energy, further increasing the sustainability of operations.

The sustainable mobile power source enabled Mammoet to not only perform the special device skidding operation with zero emission, but also off the grid. This means the solution is transferable to even relatively remote locations.

Safety through sustainability

The combined technologies used for the all-electric tunnel skidding process is a prime example of how Mammoet leads the market in making heavy lifting safer and more sustainable.

It resulted in many positive gains for the customer, including improved on-site safety due to reduced noise levels during the operation; less impact on the surrounding environment due to the absence of on-site emissions – all while maintaining the same strict timescale as normal.

The improved working environment received a positive response from the field experts working with these newly combined technologies.

“We have demonstrated that through innovative engineering and combining new and existing technology we have the ability to execute zero emission heavy lift projects for our customers – and that’s the future,” said Pascal Eeken, Manager Improvement and Innovation, Mammoet Europe.

The operation sets a new standard for carrying out heavy lifting projects using specialist equipment for jacking and skidding, in a safer, sustainable, and more eco-friendly way.

By proving out the switch to zero emissions electricity for civil projects, Mammoet is leading the way in helping customers to reduce the carbon footprint of their operations and to support more sustainable development – both for civil projects and elsewhere.