Conveyor Safety in Construction to Ensure a Secure Work Environment

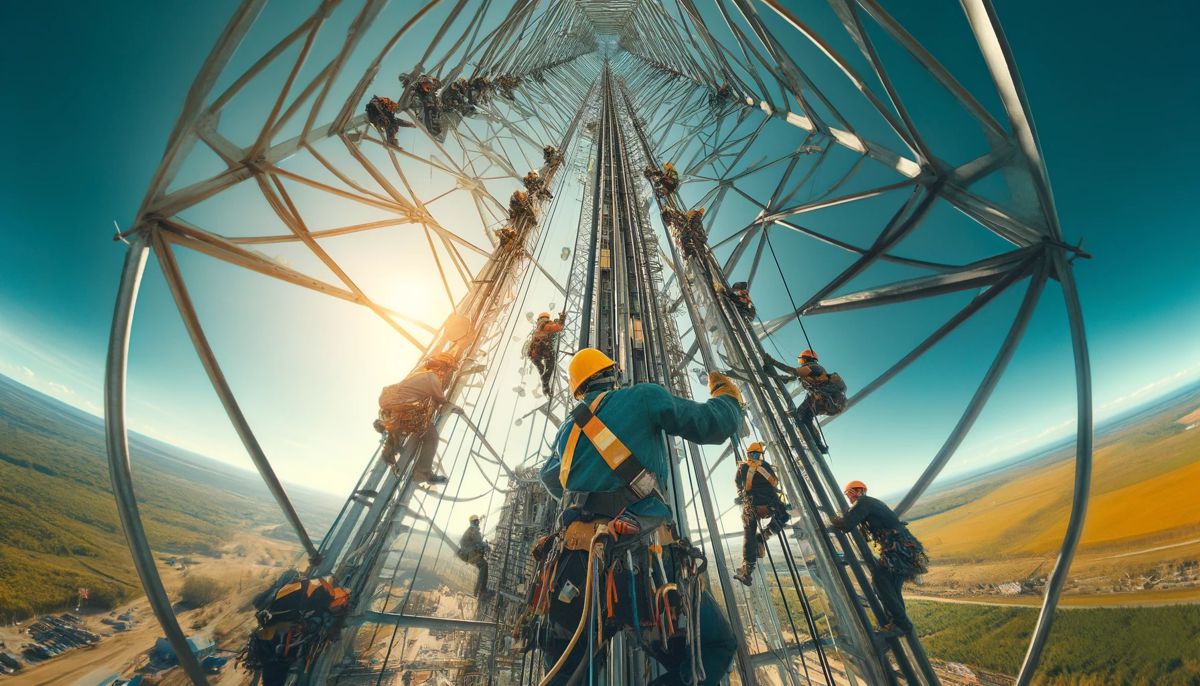

Across many different sectors of the construction industry, conveyors are used. This machinery provides an efficient way to transport materials in bulk across a building site.

Hundreds of tonnes of building materials can be moved using this equipment, and it is recognized as one of the safest and most cost-effective ways to move at volume. However, it is important to recognize that this equipment can still pose a risk to the staff that operate it. If improperly sited, poorly maintained, or overburdened with materials, the machinery can cause severe injuries (such as crushing or even entrapment of the workforce).

This article focuses on conveyor safety in the construction industry. Advice is provided that will allow construction managers and safety staff to create a secure working environment where the risk of accidents and hazards from the machinery can be kept at minimal levels.

Staff training and education

The importance of staff training and education cannot be underestimated in the construction industry, and this should also apply to the operation of conveyor systems. There is an inherent risk with any heavy machinery, and this is true of conveyors.

This risk is amplified if workers do not have a thorough understanding of how to operate it safely and the precautions that should be put in place while it is in operation. Operators should understand all aspects of the design and operation of the conveyor, paying specific attention to emergency shutdown procedures and what to do if they witness an issue or malfunction with the machinery.

Ideally, this training should be rolled out to all staff members who use the equipment or need to work on a site where a conveyor is used. It should form part of their mandatory training when being onboarded into the company and will ideally be refreshed annually as part of an ongoing comprehensive training program.

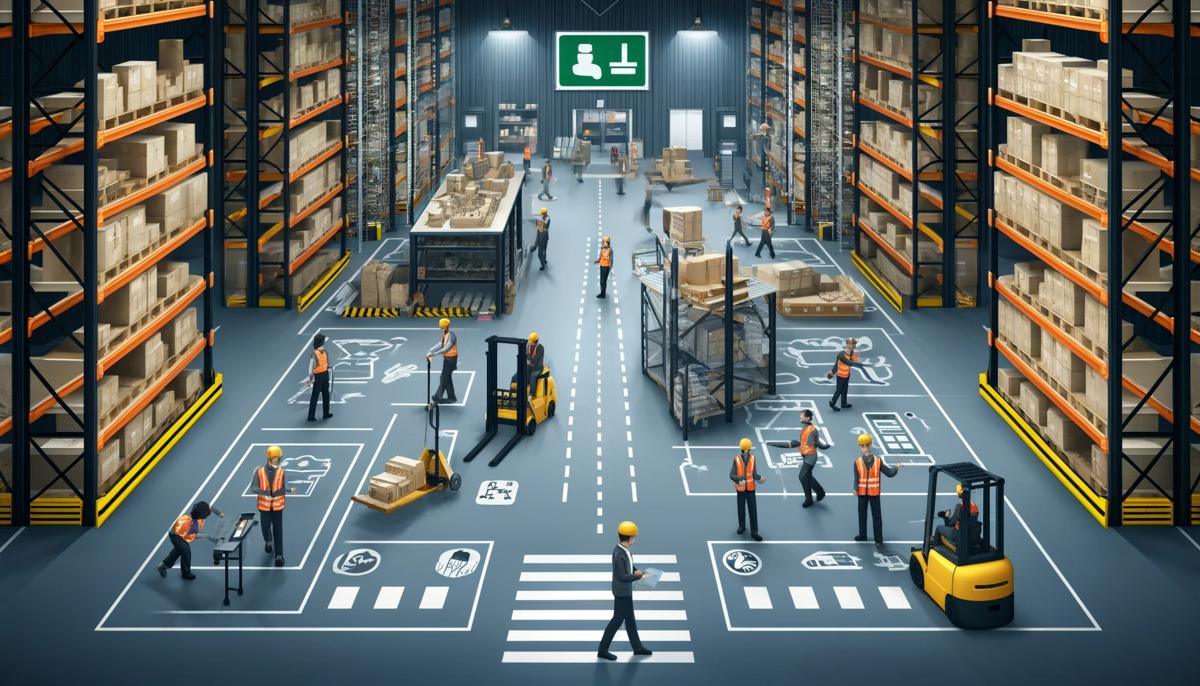

The use of PPE

Personal protective equipment (or PPE) should be used for all construction processes, and this is no different when operating a conveyor. Key PPE in this working environment includes high visibility jackets, goggles, and suitable footwear (such as steel toe-capped boots).

High visibility jackets will alert the conveyor operator to the fact that there are other workers in the vicinity. This is especially important when moving or operating a conveyor in low light conditions such as early morning or when darkness falls.

Goggles will minimize the risk of eye damage when the conveyor is in operation (such as when dust or debris falls from the machinery), and strong boots will ensure that crushing injuries to workers’ feet will not occur if any materials fall from the conveyor.

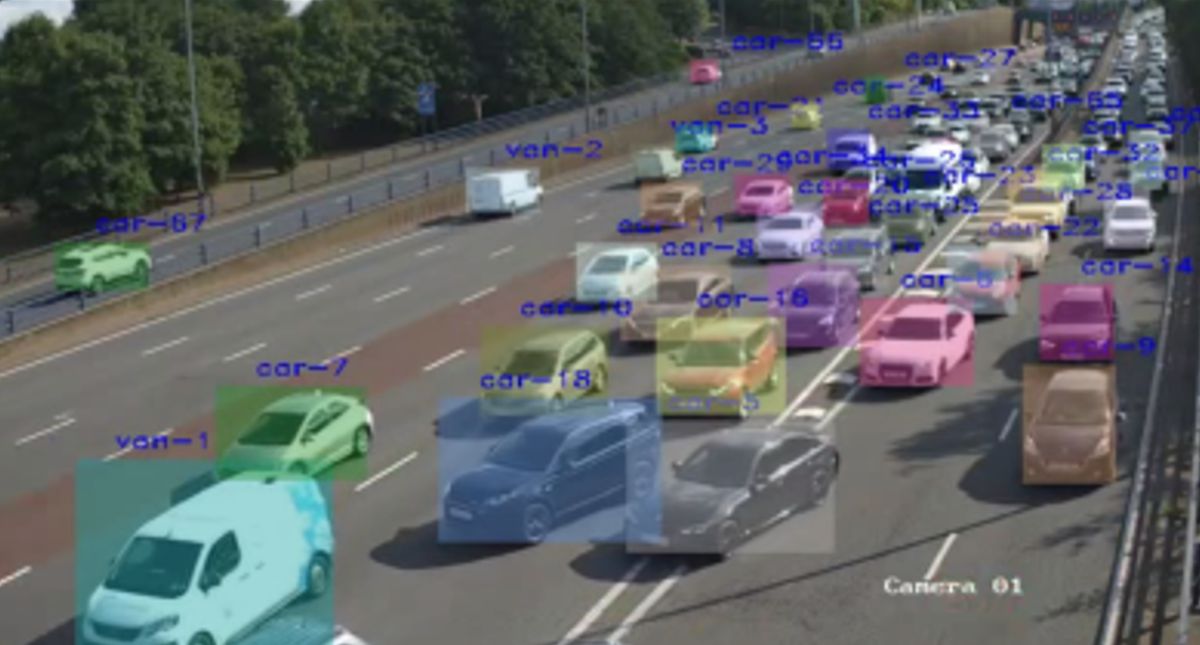

Risk assessment and reporting adverse incidents

Finally, a thorough risk assessment should be undertaken before the machinery is in operation in any environment where a conveyor is used.

Consider the terrain on which the conveyor is placed. Is the surface suitable to secure this heavy machinery and operate it safely? Is there potential for objects to fall from the conveyor while it is in operation? Is there a risk of entrapment to the workforce, and are there any pinch points that can be identified?

This risk assessment should be backed up with a reporting system for adverse incidents and “near misses.” Such systems allow a construction firm to accurately map risks in their operations, giving them the information needed to take steps that will minimize future reoccurrences.