The Role of Metalworking Fluids in the Railway Sector

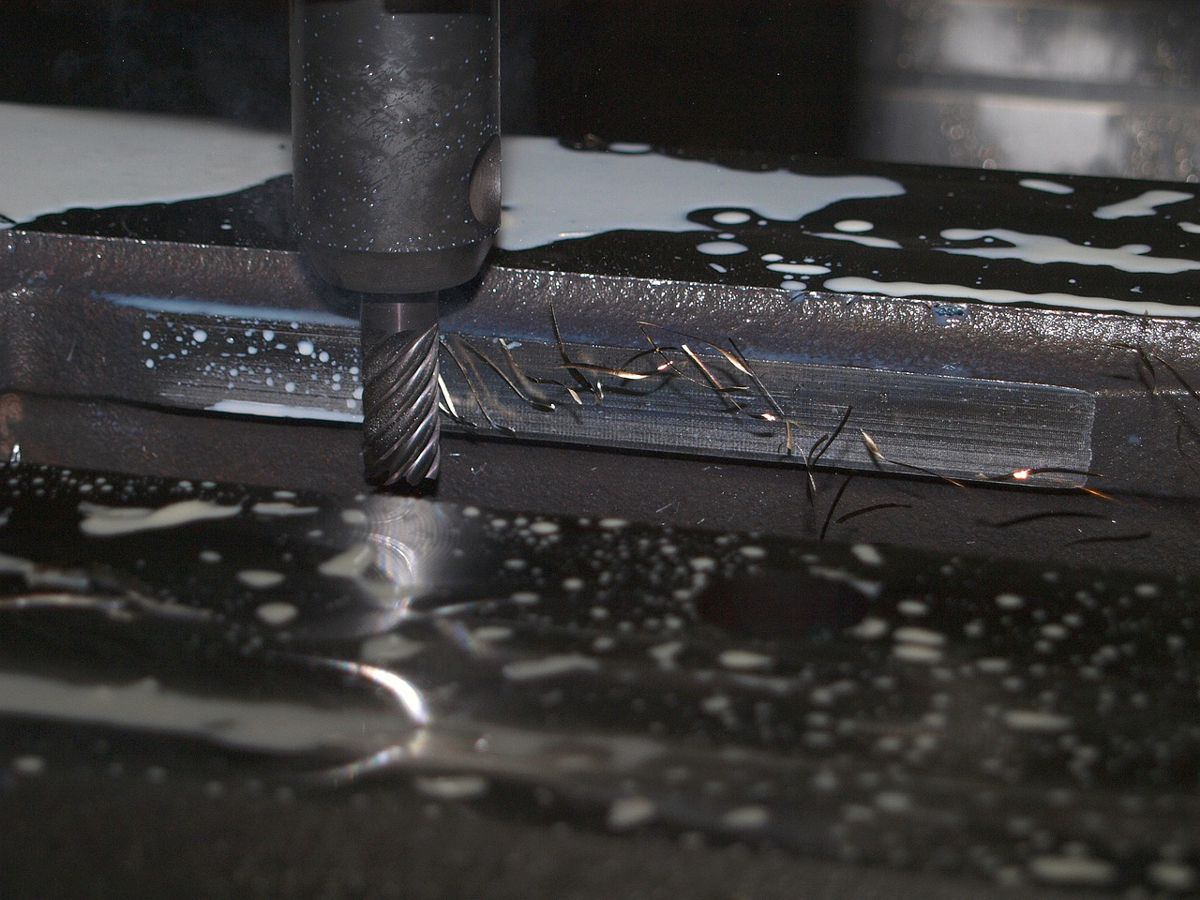

Metalworking fluids (MWFs) are an indispensable product within the railway industry, facilitating the machining and shaping of metals by providing lubrication and cooling properties.

Often referred to as suds, coolants, slurry, or soap, these fluids find their application primarily in machine shops or maintenance areas where intricate tools such as lathes, CNCs, or drills are utilised to shape metal components essential for railway operations.

Concerns Surrounding MWFs

While MWFs offer significant utility in metalworking processes, they also present notable health concerns for railway workers. Prolonged exposure to these fluids can lead to various adverse health effects, including skin irritation, dermatitis, and significant respiratory ailments such as occupational asthma and bronchitis.

The potential for debilitating and long-term health impacts on railway personnel underscores the critical importance of addressing MWF-related hazards effectively.

Routes of Exposure to MWFs

Workers in the railway sector face exposure to MWFs through multiple routes, depending on their roles and the nature of their activities.

Inhalation of mist generated during machining processes, direct skin contact with unprotected areas, and ingestion due to inadequate hygiene practices represent primary routes of exposure that necessitate careful consideration.

Implementing Effective Controls for MWF Exposure Mitigation

To mitigate the risks associated with MWF exposure, the adoption of robust control measures is imperative:

- Prevention and Control of Airborne Mists: Employing enclosed machinery, implementing local exhaust ventilation (LEV) systems, avoiding using compressed air and ensuring adequate clearance times for mist dispersal are vital strategies.

- Maintaining Fluid Quality: Regular monitoring and logging of MWF characteristics, stringent control of pH and concentration levels, and proactive measures to prevent bacterial contamination are essential.

- Minimising Skin Exposure: Implementing measures to limit direct skin contact, utilising enclosed machines or splash guards, and adopting low-pressure application techniques can significantly reduce the risk of skin-related health issues.

- Health Surveillance: Consistent health surveillance protocols, even in the presence of preventive controls, serves as a crucial step in monitoring and safeguarding the well-being of railway employees.

Additional Considerations and Resources

Beyond direct exposure during machining activities, attention must also be directed towards associated processes such as storage, dilution, cleaning, and disposal of MWFs. Comprehensive management strategies should encompass these areas to ensure adequate risk mitigation and regulatory compliance.

A wealth of resources, including guidance materials from the Health and Safety Executive (HSE) and industry associations such as the United Kingdom Lubricants Association, offer invaluable insights into best practices for MWF safety and compliance.

SOCOTEC can help

SOCOTEC’s team specialises in occupational hygiene and offers tailored support to enhance Metalworking Fluids safety in the railway sector.

Their expertise ensures comprehensive coverage of hazards, proactive measures, and worker awareness, fostering a safer work environment, so working with railway companies can prioritise safety while maintaining operational efficiency.