Oerlikon elevating Electric Vehicle Battery Safety

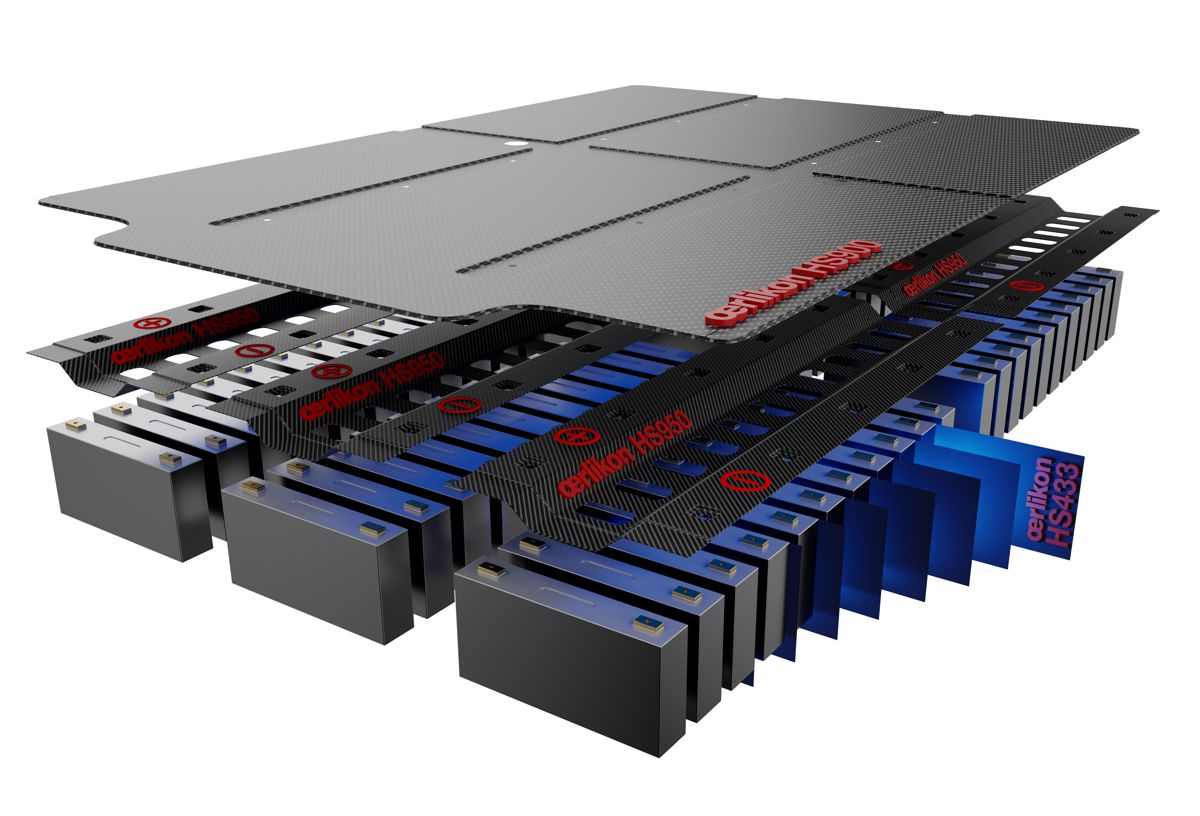

Oerlikon presents a full range of innovative customized safety components for Battery Electric Vehicles (BEVs), including pioneering heat shields, gas guidance systems, and cell separators. In the event of a battery fire, they improve the heat protection and electrical and mechanical strength of the batteries, which can save passengers’ lives.

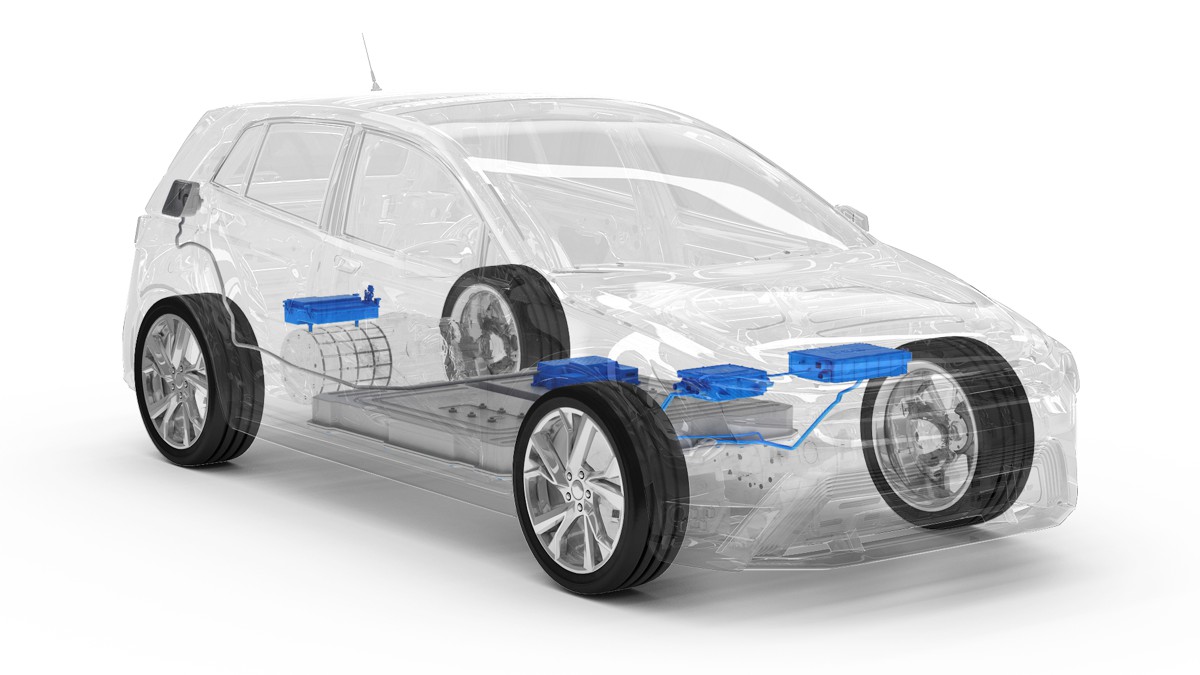

Thermal runaway poses a significant challenge in high-performance battery systems and can potentially cause extensive vehicle damage or endanger passengers.

“Oerlikon is renowned in the automotive market for its engineering expertise and materials innovation. Now we combine carefully engineered cutting-edge heat-resistant materials with an intelligent design to create thermal insulation systems that are redefining industry standards,” said Marcus Spreckels, Head of Technology TIS.

Highly heat-resistance yet thin and lightweight

The portfolio covers all critical components, from heat shields and gas guidance components to cell separators, to address the needs of any battery system and risk level. They are highly heat-resistant, mechanically durable, and yet ultra-light and thin. They insulate the critical high-voltage infrastructure of the batteries electrically and thermally, thus reducing the likelihood of battery fires spreading to the passenger area at an early stage.

From meeting the basic regulatory standards of the UN Electric Vehicle Safety Regulation (GTR 20) and their often more stringent adoption in individual countries, to exceeding the advanced requirements with Stop/Zero TP and limp-home functionality, the components are both versatile and reliable.

Customized solutions for any requirement

Unlike other manufacturers, Oerlikon does not offer standard products. Marcus Spreckels: “We develop customized solutions in terms of material and design, taking into account the specific safety requirements of each battery concept without compromising on space or weight.”

This is where Oerlikon’s experience in automotive engineering comes into play: all components are 3D-moldable, so they can be optimally tailored to the design of the battery system and the vehicle, for maximum protection. Each solution is fully customized and ready to install according to individual requirements.

Combining materials science know-how and automotive experience

Oerlikon’s thermal insulation solutions across all safety concepts and battery types on the market represent a new standard in the industry. With their deep knowledge in material science, Oerlikon’s engineers have created heat-resistant materials with new properties. Furthermore, Oerlikon’s decade-long experience in the automotive market allows customers to benefit from customized solutions from a certified manufacturer who is well-versed in the challenges associated with designing vehicles.

Series production for the entire portfolio has started at the Bremen site in the first quarter of 2024.

IATF 16949 certified and using only mica-free materials in its solutions, Oerlikon is committed not only to advancing vehicle safety, but also to environmental responsibility and ethical materials sourcing.

Visit Oerlikon at the Battery Show Europe in Stuttgart, Hall 8, Booth G85! Come by to explore our pioneering multifunctional thermal insulation solutions and meet the developers.