Prevent Corrosion in Data Centers for reliable Server operations

The digital age is booming with no signs of slowing down. That means additional servers and data centers will be needed all the time to store data, support e-commerce, perform cloud computing, and much more.

However, one small but significant issue sometimes stands in the way of a smooth server or data center launch: Corrosion. Cortec® shares several easy ways—from manufacturing to installation and beyond—to clear this obstacle out of the way and start computing!

Server Racks at Risk During Export

Industrial rackmount servers and computer systems pass through many uncontrollable environments as they are shipped around the world.

Fluctuating temperatures and humidities can create condensation within a package, leading to corrosion that may or may not be discovered before the servers malfunction.

Packaging Strategy for Computer Racks

Fortunately, this problem is easy to solve. One supplier did so by tightly covering computer system racks with VpCI®-126 Bags and placing VpCI®-132 Foam pads inside. Both materials emit Vapor phase Corrosion Inhibitor (VpCI®) molecules that diffuse throughout enclosures and form a protective molecular layer on metal surfaces.

This invisible hydrophobic barrier interrupts the interaction of moisture, oxygen, and chlorides with the metal, inhibiting corrosion.

Compostable, Biobased Packaging Options

For a more sustainable version of the same packaging strategy, computer system manufacturers and distributors can use Eco-Corr Film® (a TÜV Austria certified industrial compostable film) to shroud the racks and insert BioPads (small VpCI®-emitting pads that contain 58% USDA Certified Biobased Content) between server shelves.

These packaging materials can remain in place for continued protection until server installation.

Hydrotesting Data Center Cooling Systems

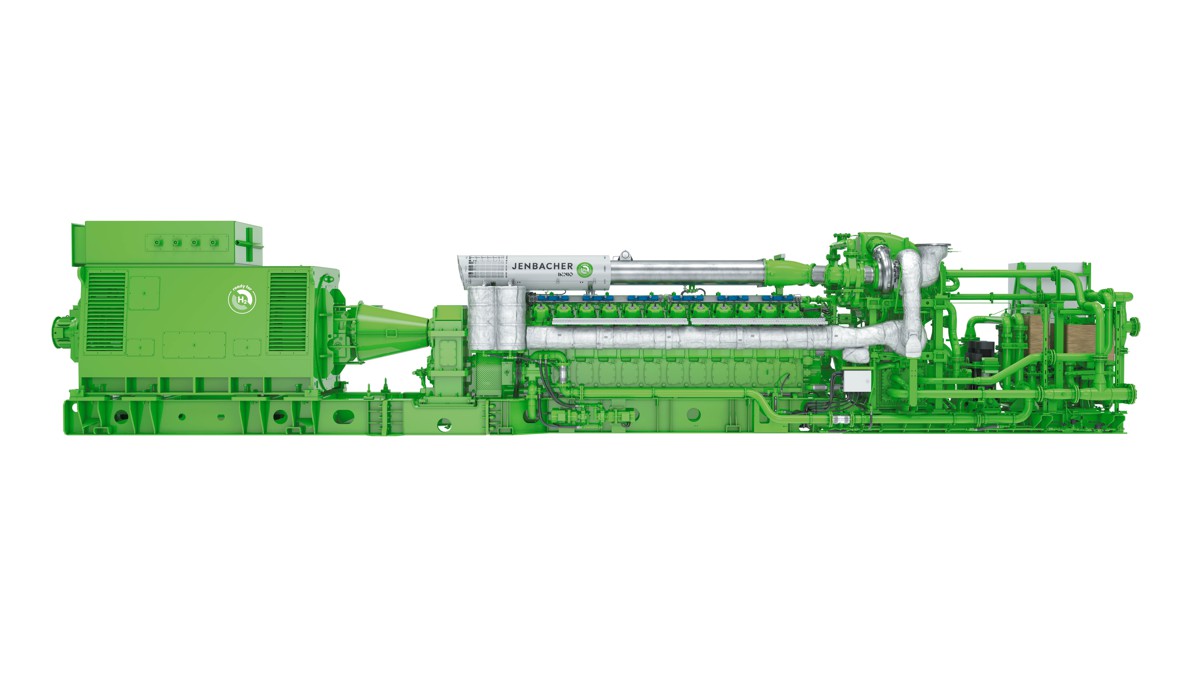

Servers generate so much heat that data centers rely on cooling systems to keep the temperature in check, especially during the summer or in hot, humid regions. Hydrotesting is a routine activity to check for leaks prior to commissioning, but it can also be a catalyst for rust formation and subsequent clogging or other rust complications.

By adding a corrosion inhibitor such as VpCI®-649 to the hydrotest water, contractors can protect cooling system piping during hydrotesting and (with the right concentration) during the interim period until data center commissioning.

Chiller Dry Layup

Depending on the corrosiveness of the environment and the length of the wait, associated chiller bundles may need protection even before the piping system is completed. Dry layup is easy to perform by placing a Cooling Tower Frog® in the void space and slitting the water-soluble bag open to allow Vapor phase Corrosion Inhibitors to condition the enclosure with protective vapours.

At start-up time, the commissioning crew can leave the Cooling Tower Frog™ in the chiller bundle and fill the system up as normal, allowing the makeup water to dissolve the Cooling Tower Frog™ and flush it away. VpCI®-648 or 649 can then be added to the chiller system for corrosion protection as part of the normal operational water treatment program.

Avoid Corrosion in the Digital Age

Corrosion is an unwelcome and unnecessary delay to getting a server started or a data center up and running.

By applying Vapor phase Corrosion Inhibitors at a few key points, distributors can ship computer racks safely to customers and contractors can commission their data center cooling systems without a corrosion delay.