The Essential Guide to Energy-Efficient Industrial Battery Chargers

Industrial battery chargers are pivotal components in various sectors, powering everything from large machinery to backup systems. In today’s environmentally conscious world, the energy efficiency of these chargers is not just a matter of reducing electricity bills but also a crucial element in sustainable industrial practices.

What are Industrial Battery Chargers?

Industrial battery chargers are devices designed to convert AC input into DC output to charge batteries efficiently and safely. They vary in type based on the application, ranging from simple transformers to sophisticated electronic systems. Key varieties include standard, multi-stage, and smart chargers, each catering to different industrial needs.

Why is Energy Efficiency Important for Industrial Battery Chargers?

Energy efficiency in industrial battery chargers brings multiple benefits:

- Environmental Impact: Efficient chargers reduce energy consumption, thereby decreasing the carbon footprint of industrial operations.

- Economic Savings: Lower energy use translates to reduced operating costs over the lifespan of the charger.

- Operational Efficiency: Efficient chargers optimize the charging time and enhance the longevity of the battery itself.

How is Energy Efficiency Measured in Industrial Battery Chargers?

To understand and improve the energy efficiency of battery chargers, several metrics are crucial:

- Charging Efficiency: The percentage of input energy converted into stored energy.

- Power Factor: The effectiveness with which the charger uses electricity.

- Energy Consumption: The total energy used by the charger during a complete charging cycle.

- Standby Power Usage: The energy consumed when the charger is plugged in but not actively charging.

What Technologies Improve the Energy Efficiency of Industrial Battery Chargers?

Several technologies have been developed to enhance the efficiency of battery chargers, including:

- Switch Mode Power Supplies (SMPS): SMPS technology offers high efficiency by converting electrical power without excessive heat generation. Pros: Reduces energy loss and improves charging speed. Cons: More complex and potentially costlier upfront.

- Pulse Width Modulation (PWM): PWM controls the energy flow to the battery by switching the power supply on and off rapidly. Pros: Precise control over charging rate, enhancing battery life. Cons: Can generate electromagnetic interference if not properly shielded.

- High-Frequency Chargers: These chargers operate at higher frequencies than traditional models. Pros: Smaller, lighter, and more efficient. Cons: Higher initial costs and may require more sophisticated maintenance.

How Do Different Industrial Battery Chargers Compare in Energy Efficiency?

When comparing industrial battery chargers, consider these aspects:

- Efficiency Rating: How effectively the charger converts AC to DC power.

- Power Output: The amount of power the charger can deliver to the battery.

- Cost-effectiveness: Balancing the upfront costs with long-term energy savings.

- Durability: Chargers designed to withstand industrial environments offer better long-term efficiency.

What are the Main Factors Affecting the Energy Efficiency of Battery Chargers?

Factors impacting efficiency include:

- Design: Advanced designs incorporate more precise control mechanisms.

- Usage Patterns: Frequent starts and stops can decrease efficiency.

- Environmental Conditions: Extreme temperatures can affect charger performance.

What are the Advantages of Using Energy-Efficient Industrial Battery Chargers?

Key benefits include:

- Reduced Energy Costs: Significant savings on energy expenses.

- Lower Environmental Impact: Contributes to a greener operation.

- Extended Battery Life: Efficient charging typically leads to longer battery life.

- Improved Performance: Optimized energy use enhances overall operational efficiency.

What Industries Benefit the Most from Energy-Efficient Battery Chargers?

Industries that gain significantly from efficient charging systems include:

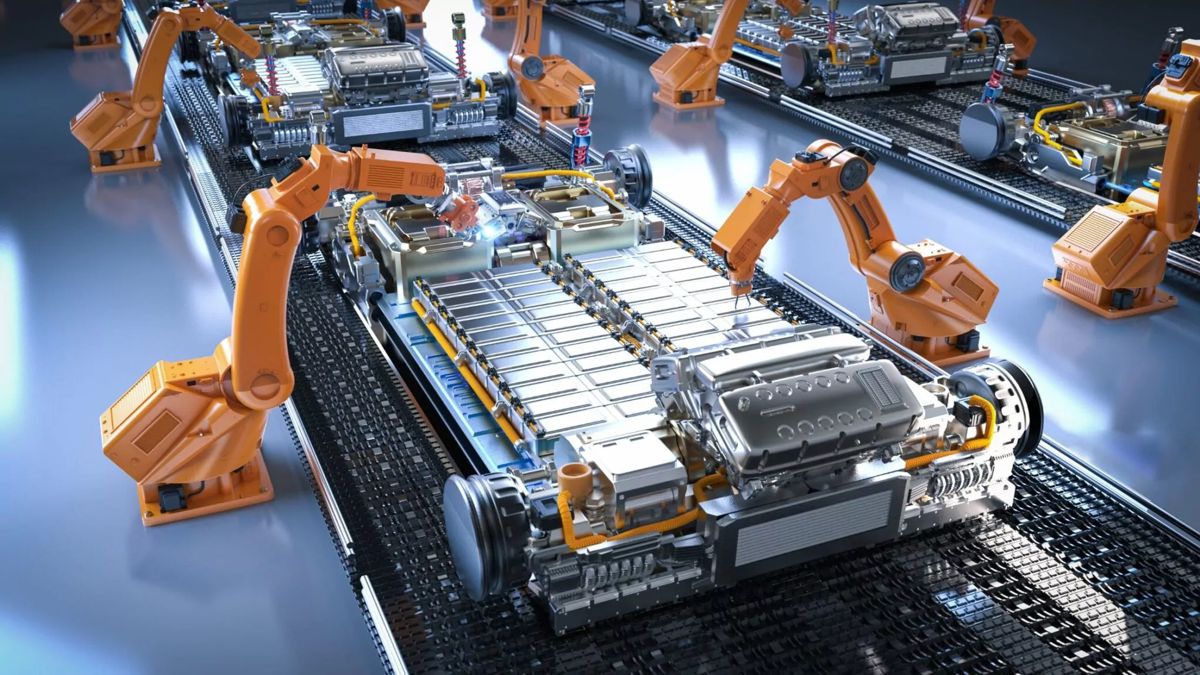

- Manufacturing: For operational machinery and automated lines.

- Warehousing and Logistics: In equipment like forklifts and transport vehicles.

- Telecommunications: Critical for maintaining communications infrastructure.

- Renewable Energy Sectors: Integral to managing storage of generated energy.

How to Choose the Right Energy-Efficient Industrial Battery Charger?

Assess Your Energy Needs

Considerations include:

- Battery Type and Capacity: Different batteries require specific chargers.

- Charging Frequency and Duration: Determines the scale and type of charger needed.

Compare Efficiency Ratings

Efficiency ratings, such as those provided by Energy Star, offer a benchmark for comparing charger performance.

Evaluate Total Cost of Ownership

Weigh the initial purchase cost against expected energy savings and maintenance expenses over the charger’s operational life.

What are the Best Practices for Using Energy-Efficient Battery Chargers?

Effective practices include:

- Regular Maintenance: Ensures optimal performance.

- Optimal Charging Cycles: Extends battery life and maintains efficiency.

- Proper Storage and Handling: Protects the charger’s operational integrity.

What are the Potential Drawbacks of Energy-Efficient Battery Chargers?

While they offer many advantages, potential drawbacks include:

- Higher Upfront Costs: More sophisticated technology often comes at a higher initial price.

- Complexity in Integration: Adapting new chargers into existing systems can be challenging.

How to Maintain Energy Efficiency in Industrial Battery Chargers Over Time?

Maintaining efficiency involves:

- Regular Inspections: To catch and fix any emerging issues.

- Firmware Updates: To keep software-driven chargers operating efficiently.

- Cleaning and Cooling: To prevent overheating and maintain efficiency.

Are There Any Regulations and Standards for Energy Efficiency in Industrial Battery Chargers?

Relevant standards include:

- Energy Star: Provides guidelines for energy efficiency.

- IEC Standards: International standards that ensure safety and efficiency.

- Local Regulations: Compliance with local energy codes and regulations.

How to Calculate the Return on Investment (ROI) for Energy-Efficient Battery Chargers?

ROI calculations should factor in:

- Initial Costs: Compared against long-term energy savings.

- Operational Improvements: Such as reduced downtime and maintenance.

What are the Future Trends in Energy-Efficient Industrial Battery Chargers?

Anticipated advancements include:

- Smart Charging Systems: Incorporate AI to optimize charging rates and patterns.

- Integration with Renewable Energy Sources: To further reduce carbon footprints.

- Advances in Battery Technology: Continuously improving efficiency and capacity.

Conclusion

Selecting the right energy-efficient industrial battery charger is not merely a cost-saving measure, but a critical step towards sustainable industrial operations.

By understanding the technologies, benefits, and considerations involved, industries can make informed decisions that lead to substantial economic and environmental benefits.