New Cat Track Wear Sensor delivers Remote Wear Monitoring and Alerts

With 120 years of undercarriage experience, Caterpillar continues to innovate, so customers get the most from their investment. Exclusive to Cat® machines and undercarriages, the proprietary Cat Track Wear Sensor remotely monitors undercarriage wear to better predict wear out, plan maintenance and increase machine uptime.

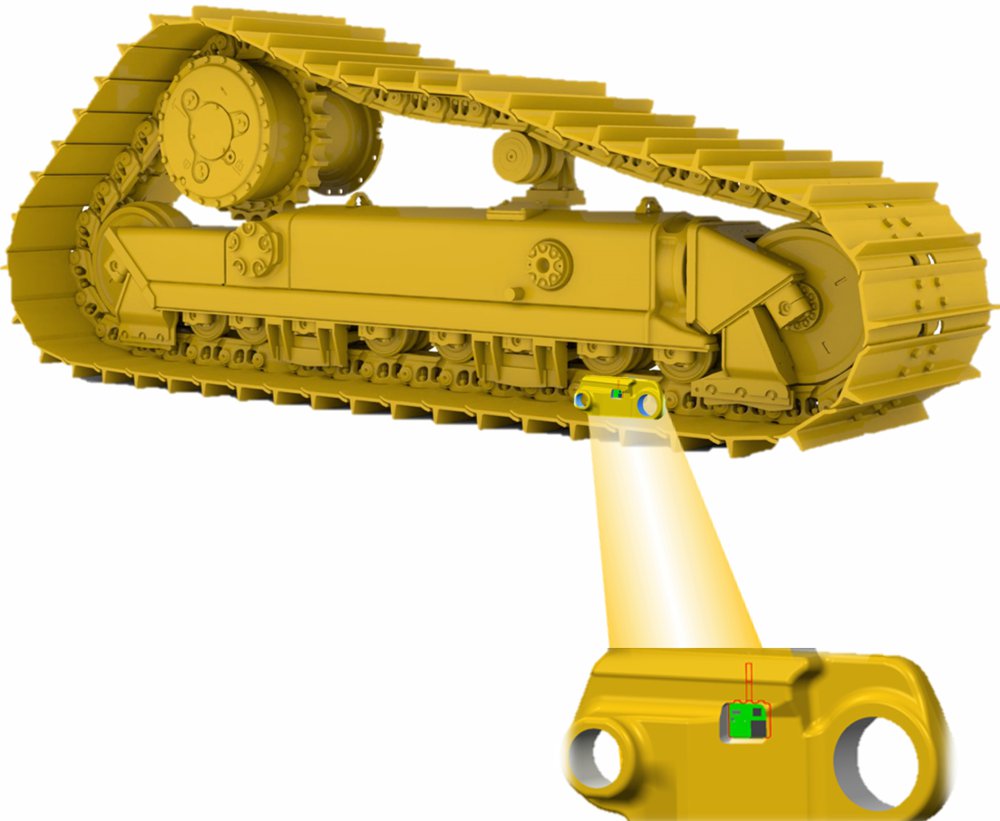

Monitored within the Cat Wear Management System, the new Cat Track Wear Sensor wirelessly communicates critical track link wear information from the machine to the dealer for monitoring.

Timed alert intervals – a 40% wear alert for possible bushing turns, 70% to signal for measuring and replacement part ordering, and 100% for required replacement – improve inspection scheduling and streamline ordering of replacement parts.

The real-time track wear status enables no-touch track link measurements, increases fleet coverage by automating inspections, provides visibility to track wear when operating in remote locations and allows for prioritized timing of service visits by helping optimize manual inspections.

Field tested for proven reliability throughout the expected track life, more than 2,000 Cat machines have been shipped with the innovative sensor technology. The small electronic sensor installs in a customized pocket in the track link for protection.

Each link assembly includes a smart link, resulting in two sensors on a machine, one on each side.

The Cat Track Wear Sensor survives high frequency shock loads and meets sensor functional and environmental tests. Subject to operating conditions, sensor battery life has been shown to last up to seven (7) years.

The wear sensor is standard on new Cat D5, D6 and D8 dozers, and 953 and 963 track loader models in select regions with planned expansion to models in the dozer line in the future. It can be retrofitted on eligible dozer undercarriages.