Vögele Dash 5 Asphalt Paver delivers safer and healthier paving

Stricter directives are bringing accident and health protection in road construction into sharper focus worldwide. Vögele has consistently geared the new “Dash 5” generation of pavers towards the health and safety of the operator: With new functions such as commissioning from ground level, integrated lighting and a revised ventilation system.

In recent years, risk awareness and safety standards in asphalt paving have increased worldwide – and with them the demands on road pavers. Depending on the country, construction companies must comply with different regulations and occupational exposure limits. For paver specialist Vögele, operator protection is therefore always at the heart of its developments.

“The road paver is not just a machine that has to function at the highest technical level, but first and foremost, it is a workplace,” says Bastian Fleischer, Product Manager at Vögele. “High-quality and efficient paving can only be guaranteed if operators can work with the paver in a safe and ergonomic manner and in compliance with health and safety standards. Good working conditions reduce illnesses and accidents. Regardless of country-specific regulations, operator safety is therefore at the forefront of all our developments, especially with the new Dash 5 generation.”

Commissioning at the press of a button

Vögele has developed the automatic Paver Access Control (PAC) function to make preparations for paving even safer. The control unit positioned on the screed allows operators to start all the initial steps – such as switching on lights, starting the diesel engine, booting up the machine control system, putting up the hardtop and locking it in position, as well as lowering the screed – at the push of a button from ground level. At the end of work, the paver can be moved to the transport position in the same way.

This makes commissioning and decommissioning as well as loading onto a low-bed trailer safer and more convenient. In the dark, the operator starts the lighting before climbing onto the paver and thus has optimum visibility. Functions such as automatic hardtop locking prevent the operator from forgetting important steps during commissioning. “PAC avoids mistakes caused by carelessness and ensures absolute reliability thanks to the clear sequence of the initial steps,” says Fleischer.

Targeted illumination without mounting

Adequate lighting on and around the road paver is another safety factor on night-time jobsites, in poor visibility or in tunnels. Therefore, Vögele has optimised the lighting concept of the Dash 5 generation: Integrated LED lighting illuminates the operator’s platform and all service points accessible from there even better. The illumination of the tow point cylinders and freely positionable spotlights guarantee a good view of all relevant areas.

Instead of the light balloons, the new models can also be equipped with additional LED spotlights that are permanently installed in the hardtop extension. They evenly illuminate the entire working area up to four metres behind the screed and up to a pave width of ten metres. At the end of work, the lighting switches off automatically using the timer function, giving the operator enough time to leave the jobsite safely.

“Our new lighting concept reduces the risk of accidents and operating errors because the powerful LEDs illuminate precisely those areas that are relevant for commissioning, paving or servicing,” says Fleischer. “What is more, the paving team does not need to transport separate light sources and install them on the jobsite. This minimises the risk of accidents and saves time by eliminating setup and idle times.”

Less noise, lower emissions

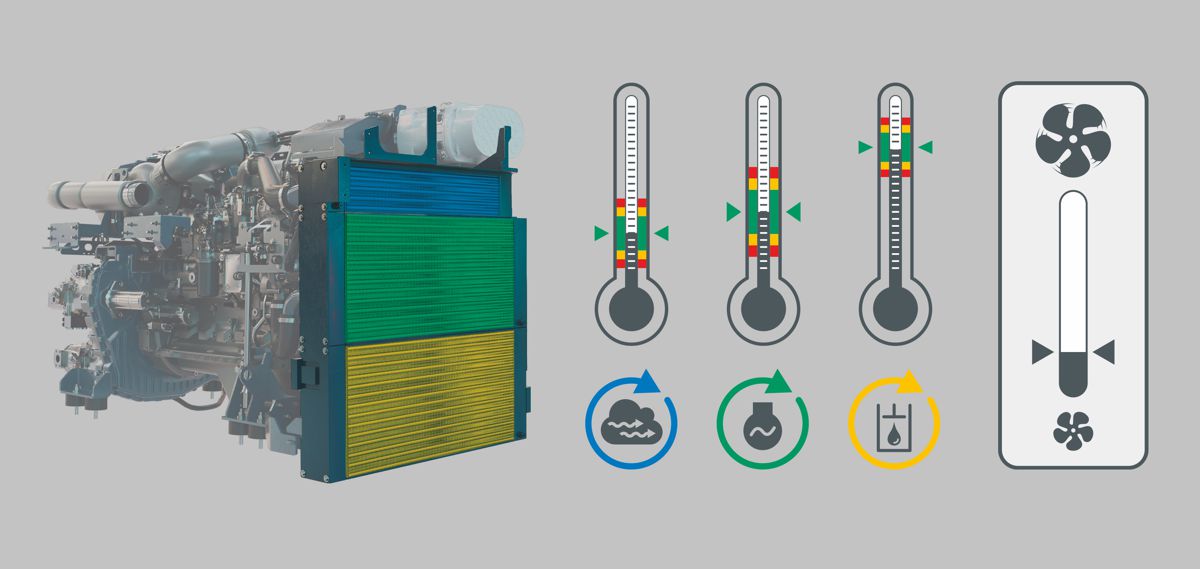

The Dash 5 road pavers also offer operators better health protection and road construction companies a better sustainability footprint. This is because Vögele has further reduced noise and CO₂ emissions with the same engine power. This is achieved by the revised drive with the optimised EcoPlus emission reduction package: As with the previous generation, various technical features ensure lower consumption and emissions.

In the Dash 5 generation, however, Vögele has optimised the variable-speed fan so that the fan speed is calculated even more precisely and is only increased to the extent necessary to operate the machine safely. This significantly reduces noise and CO₂ emissions as well as consumption.

Less noise, lower emissions

The Dash 5 road pavers also offer operators better health protection and road construction companies a better sustainability footprint. This is because Vögele has further reduced noise and CO₂ emissions with the same engine power. This is achieved by the revised drive with the optimised EcoPlus emission reduction package:

As with the previous generation, various technical features ensure lower consumption and emissions. In the Dash 5 generation, however, Vögele has optimised the variable-speed fan so that the fan speed is calculated even more precisely and is only increased to the extent necessary to operate the machine safely. This significantly reduces noise and CO₂ emissions as well as consumption.

Reduced exposure

In order to protect operators from aerosols even more efficiently during asphalt paving, Vögele is also continuously enhancing the ventilation system of its road pavers.

“We have been offering a NIOSH-certified extraction system for our machines for many years,” says Steffen Fickeisen, Head of Special Machinery at Vögele. “With the Dash 5generation, we have now significantly increased the extraction performance once again and optimised the outlet: It is now integrated in the paver hardtop instead of at the rear of the operator’s platform, which further reduces the driver’s exposure.”

Further optimisations are currently being implemented. “We will then not only equip our latest machines with these, but also offer a retrofit package for our Dash 3 models,” says Fickeisen.

Better ergonomics, better organisation

In addition to technical solutions for reduced exposure to emissions, better illumination and new automatic functions, Vögele supports the health and safety of operators by improving ergonomics and organisation.

With the enhanced ErgoPlus 5 operating concept, new comfort functions, pivot-mounted driver’s seats, two-stage seat heating, insulated sunshades, luggage nets and cup holders, the Dash 5 road pavers are consistently geared towards the needs of the operators. Pluggable tool holders, new transport solutions such as Logistic Plus and mounting and positioning aids ensure a tidy workplace, safe transport and fewer errors during assembly.

“Our aim is to create all the conditions for optimum working conditions with the new road pavers and thus increase the quality of paving jobs and the productivity of road construction companies,” says Fleischer.