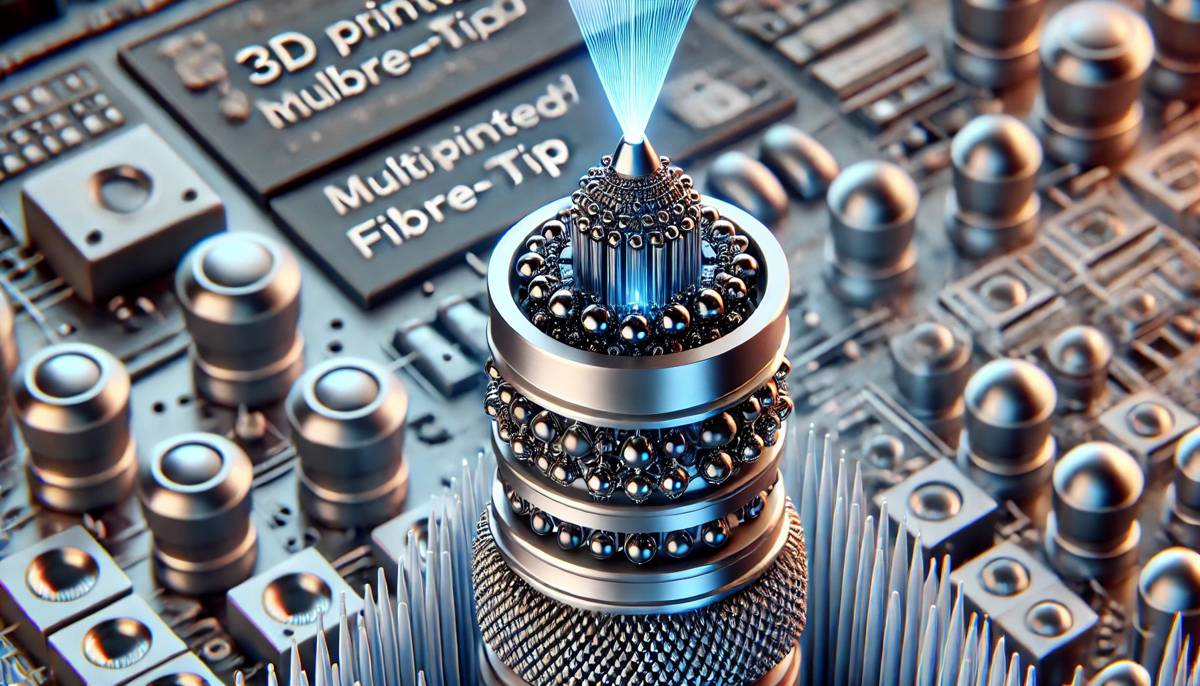

3D Printed Multicore Fibre Sensors for Magnetic and Temperature Measurements

In a world increasingly reliant on smart technologies and precise measurement systems, the demand for ultra-compact, highly sensitive sensors has never been higher. Enter the ground-breaking 3D printed multicore fibre (MCF) sensors—tiny yet powerful devices that could reshape how we measure magnetic fields and temperature in fields as varied as medical diagnostics, transportation, and aerospace.

These sensors, developed by a team of scientists led by Professor Limin Xiao from Fudan University in China, are not just innovations; they are game-changers. Let’s dive into what makes these sensors tick and why they are capturing the attention of the scientific and industrial communities alike.

The Challenges of Traditional Fibre-Based Sensors

Magnetic field sensors have become essential tools in numerous industries. They’re used to monitor everything from medical equipment and transport systems to advanced aerospace technologies. Optical fibre-based magnetic field sensors, in particular, are valued for their compact design, high sensitivity, long-distance data transmission, and relatively low cost. But there’s a catch.

Temperature fluctuations can significantly interfere with the accuracy of these sensors, leading to measurement errors. While some workarounds, like integrating multiple sensing elements, can mitigate temperature crosstalk, these solutions typically result in bulkier setups and a higher potential for spatial measurement errors. The increased size of these multi-element sensors makes them less practical for space-constrained applications, limiting their overall effectiveness.

Breaking New Ground with 3D Printed Multicore Fibre Sensors

Addressing these challenges head-on, Professor Limin Xiao’s team has developed an innovative solution that combines 3D printing technology with multicore fibre optics. As detailed in their recent publication in Light: Advanced Manufacturing, this approach promises to change the game by offering discriminative sensing of magnetic fields and temperature without the usual trade-offs in size and accuracy.

Using a cutting-edge two-photon polymerisation (TPP) technique, the team crafted two distinct microstructures onto different cores of an MCF. One core features a bowl-shaped microcantilever incorporating an iron ball, specifically designed to be sensitive to magnetic fields.

The second core contains a microfluid-infiltrated microcavity that serves as a highly sensitive temperature sensor. Together, these elements work seamlessly to provide reliable, accurate measurements by utilising a sensitivity coefficient matrix that distinguishes between magnetic and thermal influences.

Key Benefits of the 3D Printed MCF Sensors

- Ultracompact Design: By integrating multiple sensing capabilities within the tiny tip of a single fibre, the new MCF sensors offer a level of miniaturisation that was previously unattainable. This is particularly valuable in applications where space is at a premium, such as inside medical devices or aerospace components.

- Enhanced Sensitivity and Accuracy: The MCF sensors excel at providing discriminative measurements of magnetic fields and temperature, eliminating the temperature crosstalk that plagues conventional sensors. This ensures higher reliability and precision, making them ideal for critical applications.

- On-Demand Customisation: One of the most exciting aspects of this technology is the ability to print these sensors on demand. Customised probes can be manufactured quickly and adapted to specific environments or experimental needs, opening the door to rapid prototyping and specialised applications.

- Reduced Error in Multi-Parameter Sensing: By keeping all sensing elements within a single, compact structure, the MCF sensors avoid the spatial discrepancies that often cause errors in multi-parameter systems. This design not only simplifies the sensing setup but also improves overall performance.

Paving the Way for Future Applications

This breakthrough technology is more than just a new type of sensor; it’s a versatile platform that can be adapted for various future applications. The bowl-shaped microcantilever, for example, isn’t just a magnetic field detector. Its design offers potential for incorporating other functional materials and microstructures, extending its utility far beyond what was previously possible.

“The bowl-shaped microcantilever can also provide a useful platform for incorporating microstructures with fruitful functional materials, extending the multi-parameters sensing scenarios, and promoting applications of MCFs,” the scientists predict. This foresight hints at an exciting future where these sensors could be adapted for even more complex measurement tasks, further enhancing their value across multiple industries.

Expanding the Potential of Sensing Technology

The advent of 3D printed MCF-tip sensors marks a significant leap forward in the field of optical sensing technology. By combining magnetic field and temperature measurements into a single, ultra-compact sensor, these devices offer a solution that is not only more efficient but also more practical for a wide range of applications. From enhancing safety in transportation to improving diagnostic capabilities in healthcare, the potential uses for this technology are vast.

Moreover, the ability to print these sensors on demand means that the technology can be quickly adapted and scaled, responding to the evolving needs of various sectors. This flexibility could accelerate research and development, providing faster paths to market for new sensing solutions.

Industry Implications: A Bright Future for High-Precision Sensors

The introduction of 3D printed multicore fibre-tip sensors represents a promising advancement with broad implications for industries that rely on precise measurements. For construction professionals, industry investors, and policymakers, this technology could mean improved safety, greater efficiency, and new possibilities for innovation.

As industries continue to push the boundaries of what’s possible with smart technologies, the need for reliable, accurate, and compact sensors will only grow. The work of Professor Xiao and his team not only addresses current challenges but also lays the groundwork for future advancements in sensor technology.

These sensors could soon become an indispensable tool in environments where space is limited, precision is critical, and adaptability is a must. In an increasingly connected and data-driven world, such innovations aren’t just welcome—they’re essential.